Lamp part subpackaging equipment

A technology of packaging and parts, which is applied in the field of lighting parts packaging equipment, can solve the problem that there is no way to adjust the size of lighting parts according to the actual use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

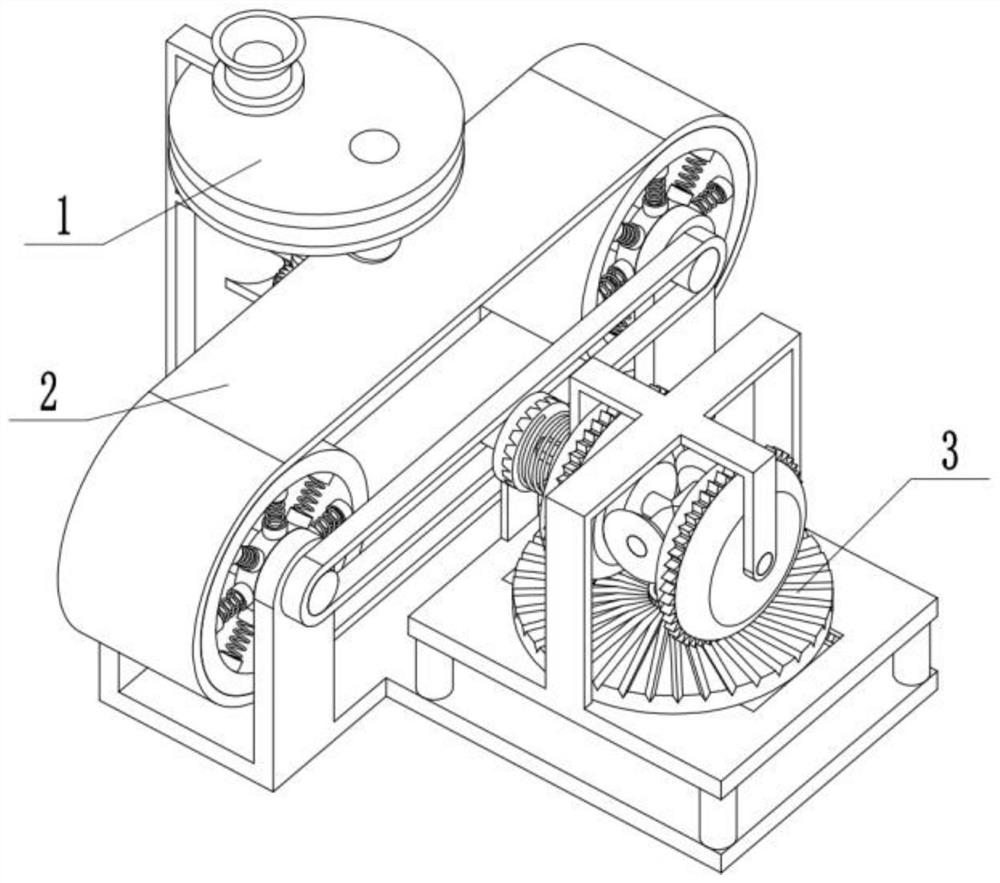

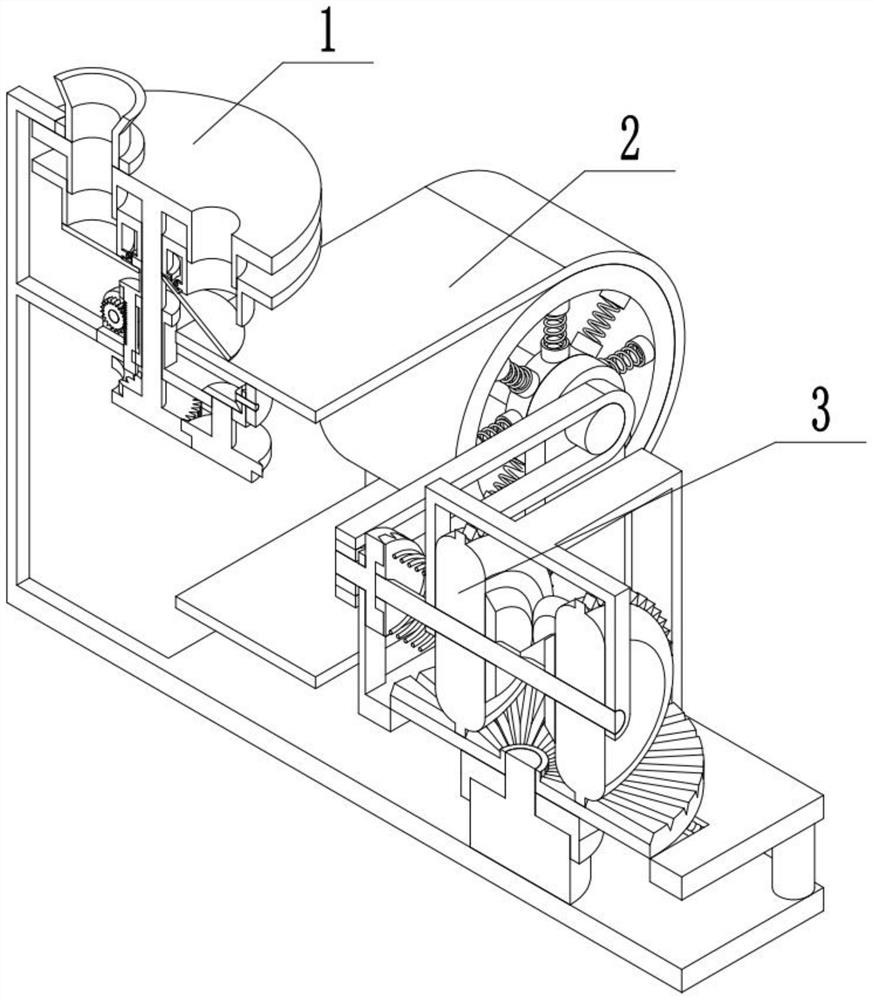

[0029] Combine below Figure 1-12In this embodiment, a lamp parts subpackaging device includes a subpackaging assembly 1 , a carrying assembly 2 , and a driving assembly 3 . The subpackaging assembly 1 is connected to the carrying assembly 2 , and the carrying assembly 2 is connected to the driving assembly 3 .

specific Embodiment approach 2

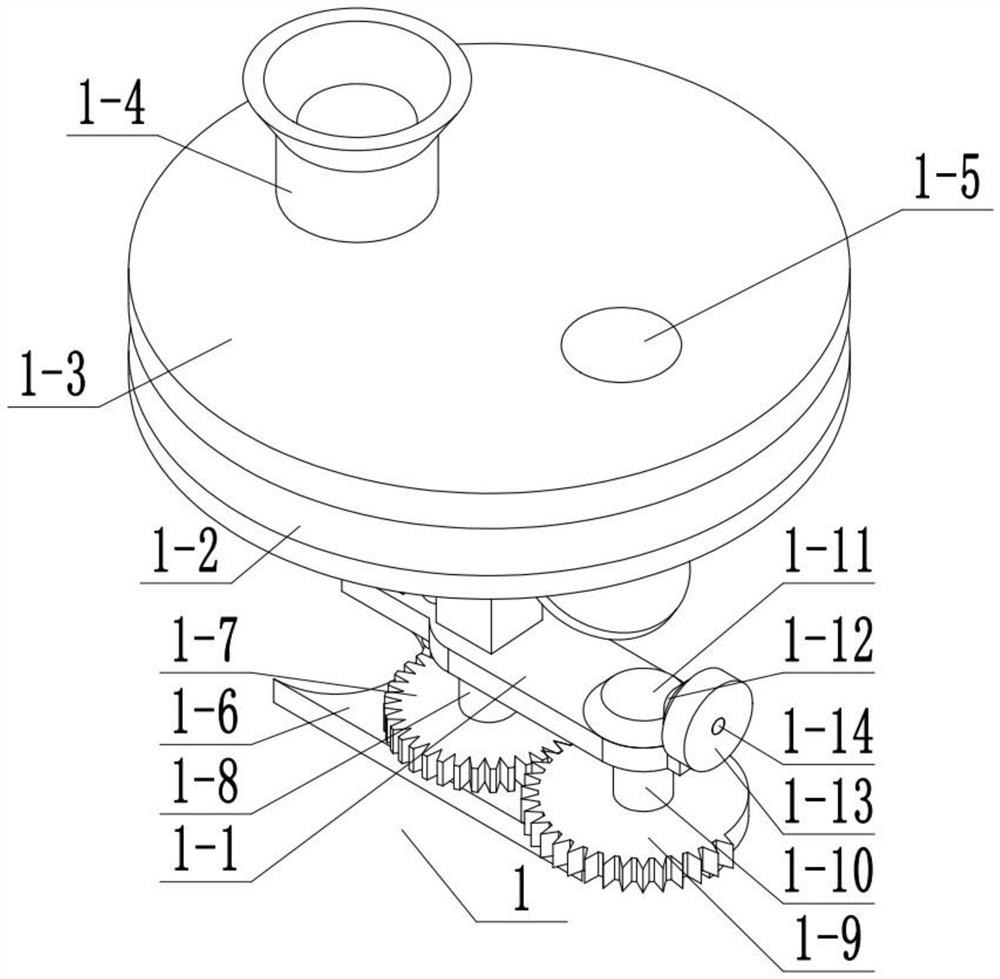

[0031] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 1, the subpackage assembly 1 includes a subpackage bracket 1-1, a middle drive plate 1-2, an upper drive plate 1-3, and a feed pipe 1-4 , Feeding casing 1-5, matching plate 1-6, straight gear one 1-7, straight gear shaft one 1-8, half straight gear two 1-9, straight gear shaft two 1-10, bevel gear one 1 -11, bevel gear 2 1-12, driving friction wheel 1-13, bevel gear shaft 1 1-14, driving rotating rod 1-15, adjusting straight gear 1-16, flipping cover 1-17, passive matching rod 1 -18, expansion sleeve 1-19, driving boss 1-20, driving groove 1-21, adjusting rack 1-22, manual rotating rod 1-23, inner end clamping rod 1-24, inner end clamping Rod push spring one 1-25, inner end card slot one 1-26, semicircular boss 1-27, the material casing 1-5 is arranged on the upper end drive plate 1-3, and the feeding pipe 1-4 Connected with the material sleeve 1-5, the spur shaft 1-8 ...

specific Embodiment approach 3

[0034] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 1, the contact surface between the middle end drive plate 1-2 and the spur shaft 1-8 is non-circular, and the turning cover 1-17 and the expansion sleeve 1 The specification of -19 is adapted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com