Non-excavation capacity expansion method for urban old pipelines

A trenchless, pipeline technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as suboptimal solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A trenchless expansion method for urban old pipelines, comprising the steps of:

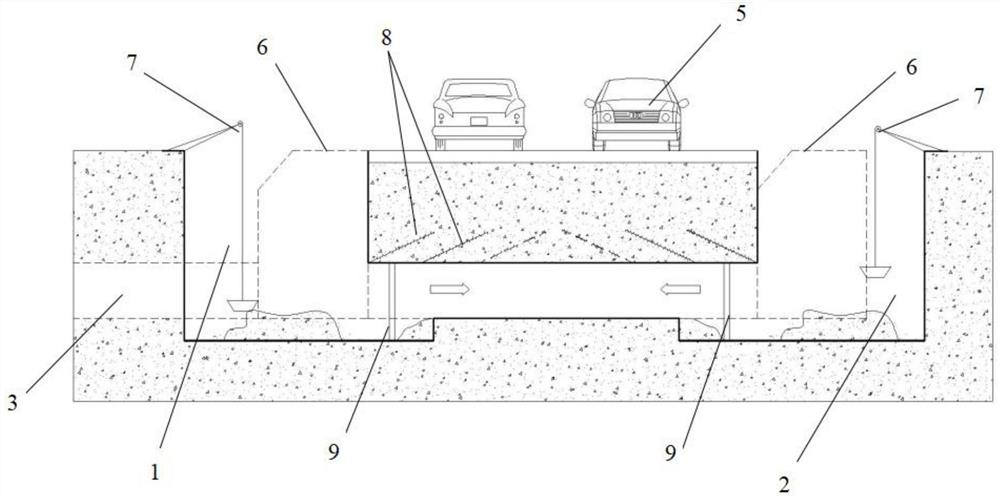

[0024] S1. If figure 1 As shown, after determining the target old pipe 3 that needs to be transformed, the old inspection wells 6 at both ends of the old pipe 3 are temporarily blocked to block drainage, and the water in the old pipe 3 is drained to create dry construction conditions; then, Transform the old inspection wells 6 at both ends into working pit 1 and receiving pit 2;

[0025] Under normal circumstances, the working pit 1 and the receiving pit 2 are located on both sides of the current road, do not occupy the motorway, and do not affect the normal passage of road vehicles 5 during the trenchless expansion construction;

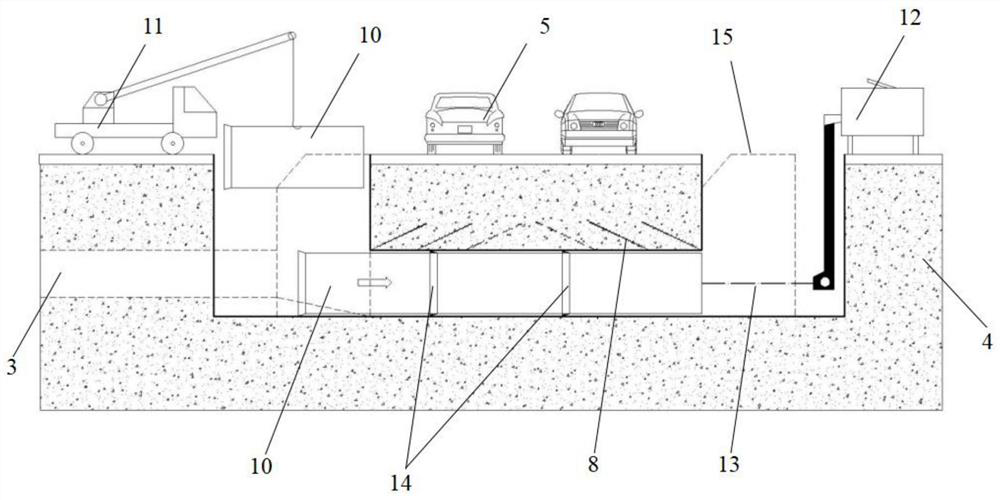

[0026] The size of the working pit 1 meets the hoisting requirements of the new pipe joint 10. If the length of the new pipe joint 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com