Construction method of rigid primary support of mould-building concrete of plateau permafrost tunnel

A technology of primary support and construction method, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as unguaranteed construction safety and quality, high rebound rate of shotcrete, and difficulties in tunnel construction, and achieve high-quality and efficient construction Requirements, excellent engineering quality, low cost of maintenance and later rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

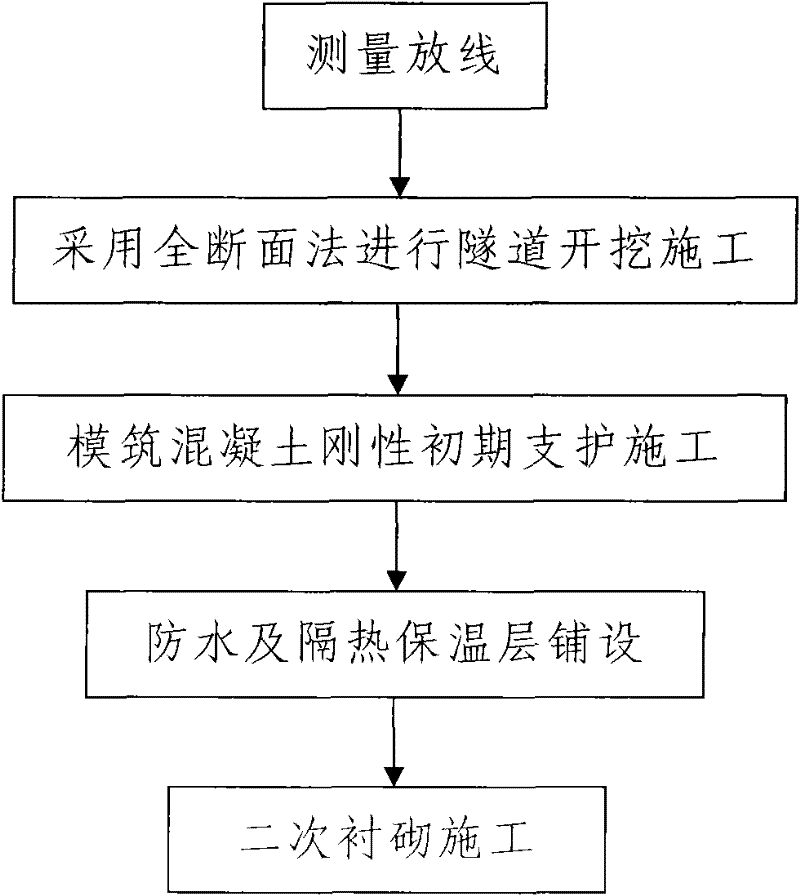

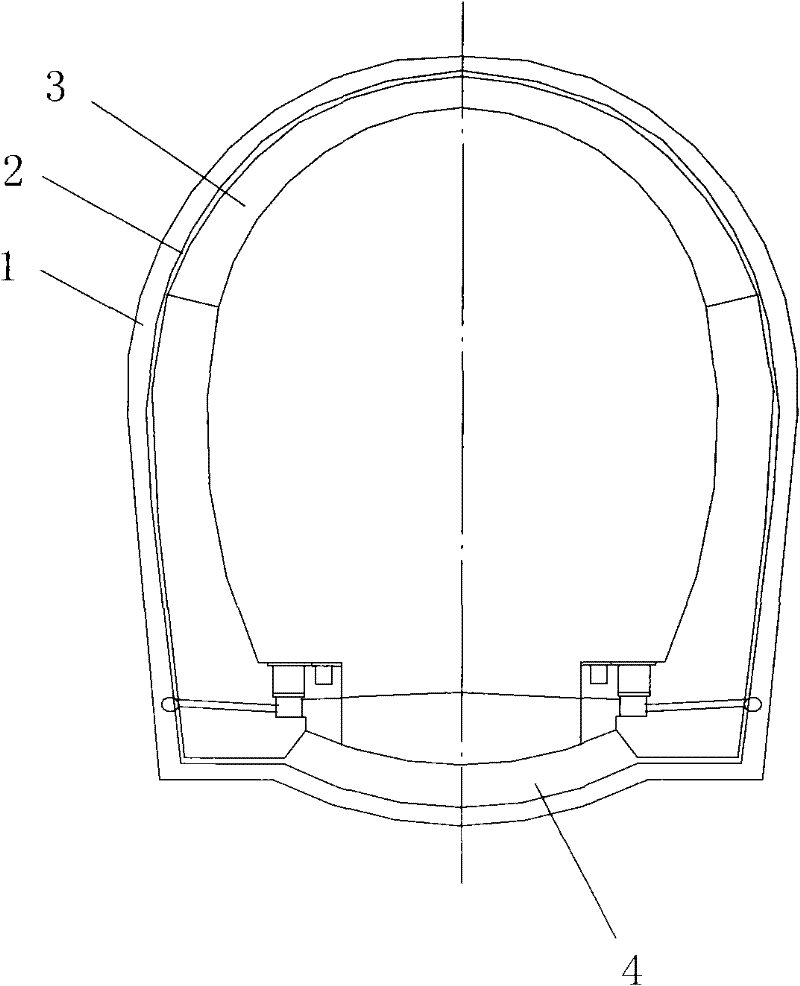

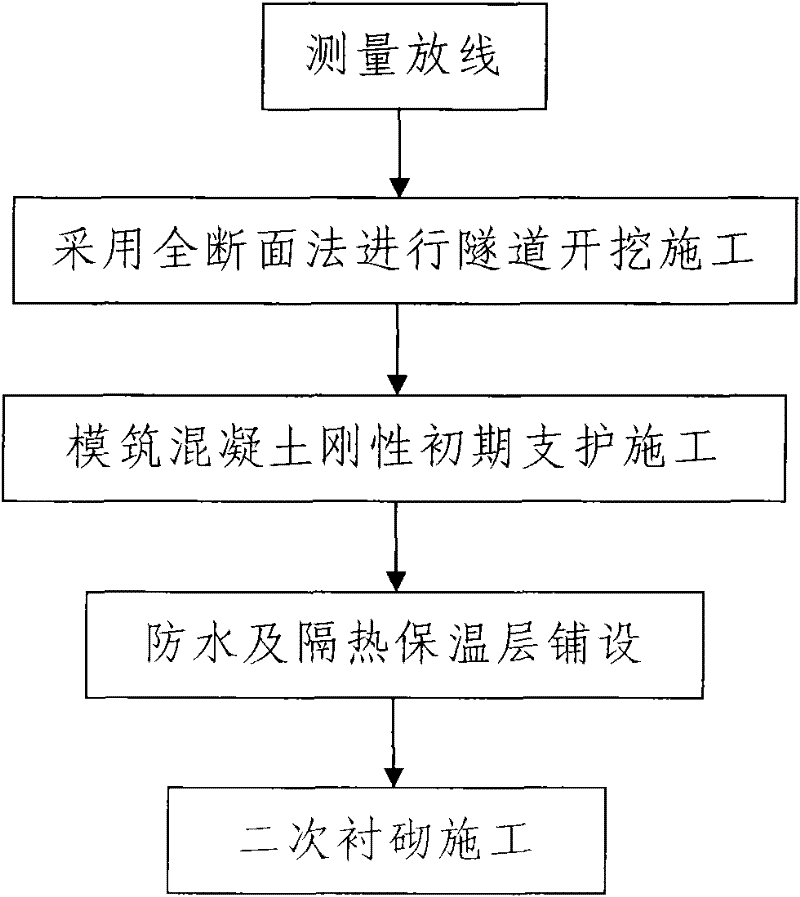

[0043] Such as figure 1 A construction method for the molded concrete rigid primary support of a plateau permafrost tunnel shown comprises the following steps:

[0044] Step 1, measurement and setting out: carry out construction measurement at the construction site according to the design drawings, and measure the center line and peripheral sideline of the plateau frozen soil tunnel 4 to be constructed at the tunnel entrance of the plateau frozen soil tunnel 4 to be constructed.

[0045] Step 2. Tunnel excavation construction: use the full-section excavation method to excavate the plateau permafrost tunnel 4 to be constructed and divide it into multiple sections; and during the excavation process of each section, synchronously excavate Complete the inner wall of the tunnel body by evenly spraying a layer of concrete mixed with concrete early strength agent inside, and correspondingly form a layer of primary sprayed concrete layer with a thickness of 3cm to 5cm.

[0046] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com