Drying device used for kit

A technology of drying device and kit, which is applied to drying, drying machine, heating device and other directions, can solve the problems such as failure to put the kit into use in time, reducing the drying efficiency of the kit, and inability to dry the kit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

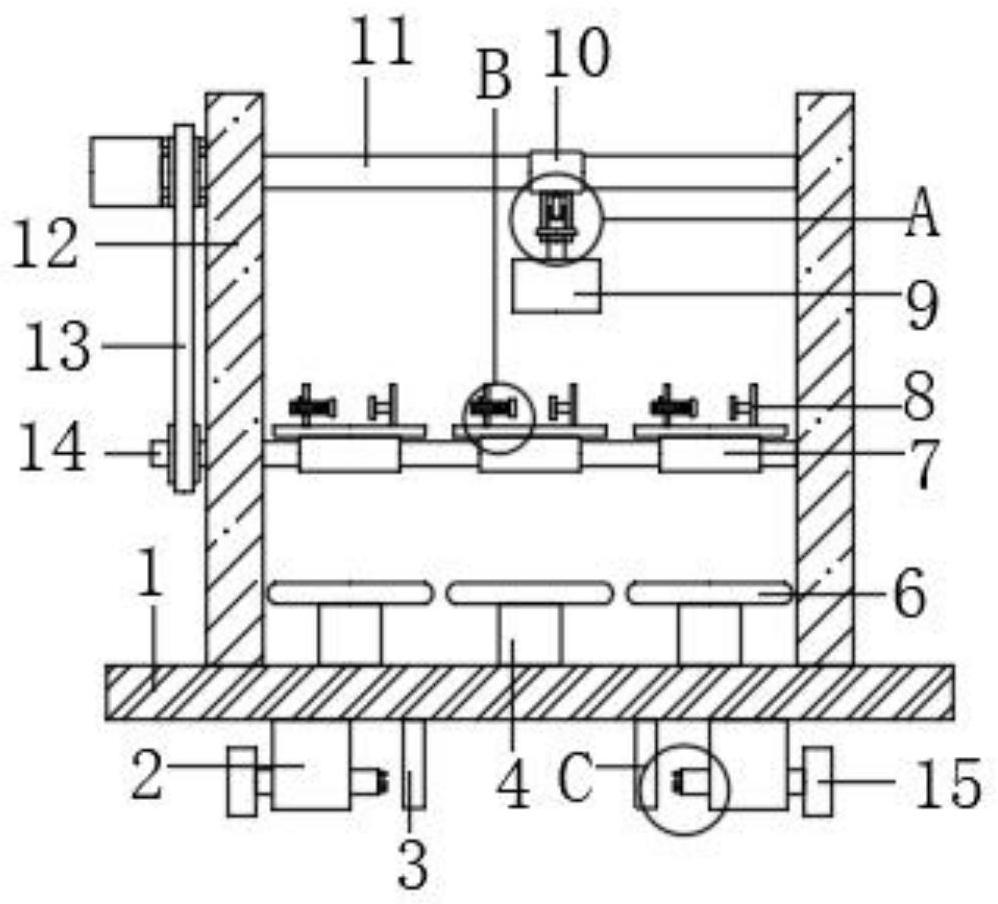

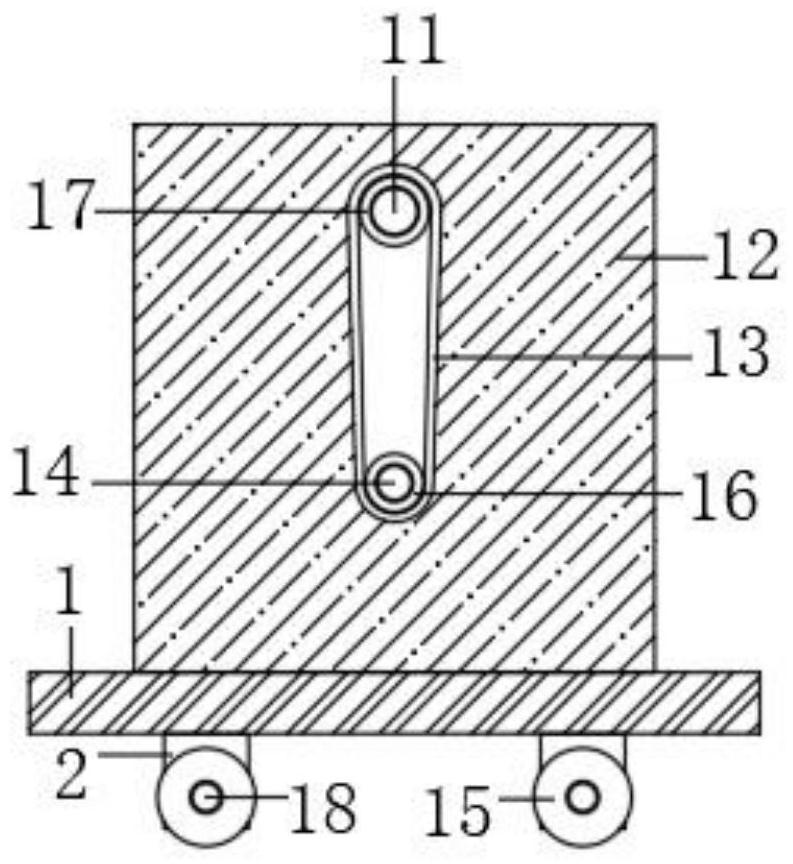

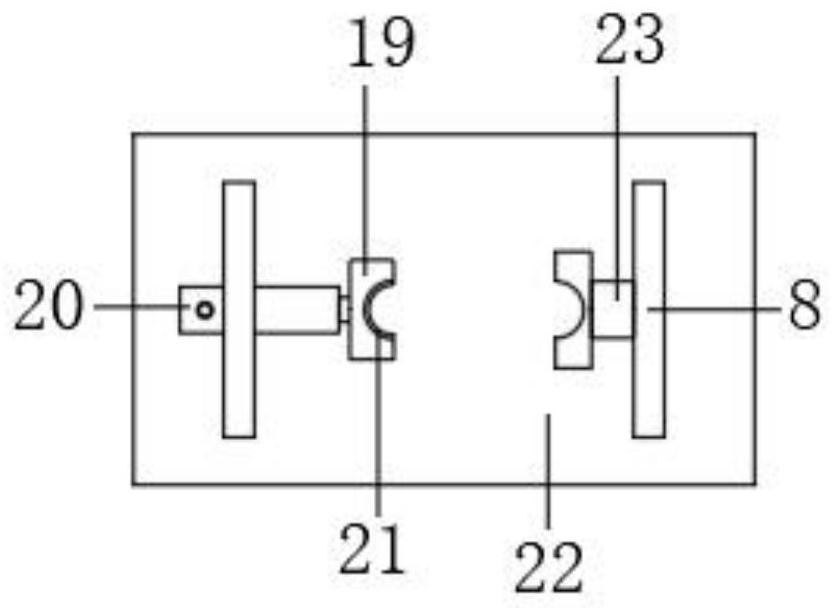

[0026] Refer Figure 1-6 A kit for drying device, comprising a base plate, the base plate 1 fixed symmetrically connected to two fixing plates 12, 12 is provided between the two fixed plates disposed transversely reciprocating screw 11 and the rotary shaft 14, each fixed plate 12 are rotated and the reciprocating screw 11 and the connecting shaft 14 is rotated, the reciprocating screw 11 is connected to the threaded sleeve 10 slides, a fixed block 27 is fixedly connected to the sliding sleeve 10, the fixed block 27 is provided for drying the kit of heat lamp 9, the fixing block 27 is provided with a heat lamp and rotation mechanism for use with 9, is fixedly connected for reciprocall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com