Drying box capable of facilitating batch placement and used for electronic product production

A technology for electronic products and drying boxes, which is applied in drying, drying machines, drying solid materials, etc., and can solve problems such as low work efficiency and long waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

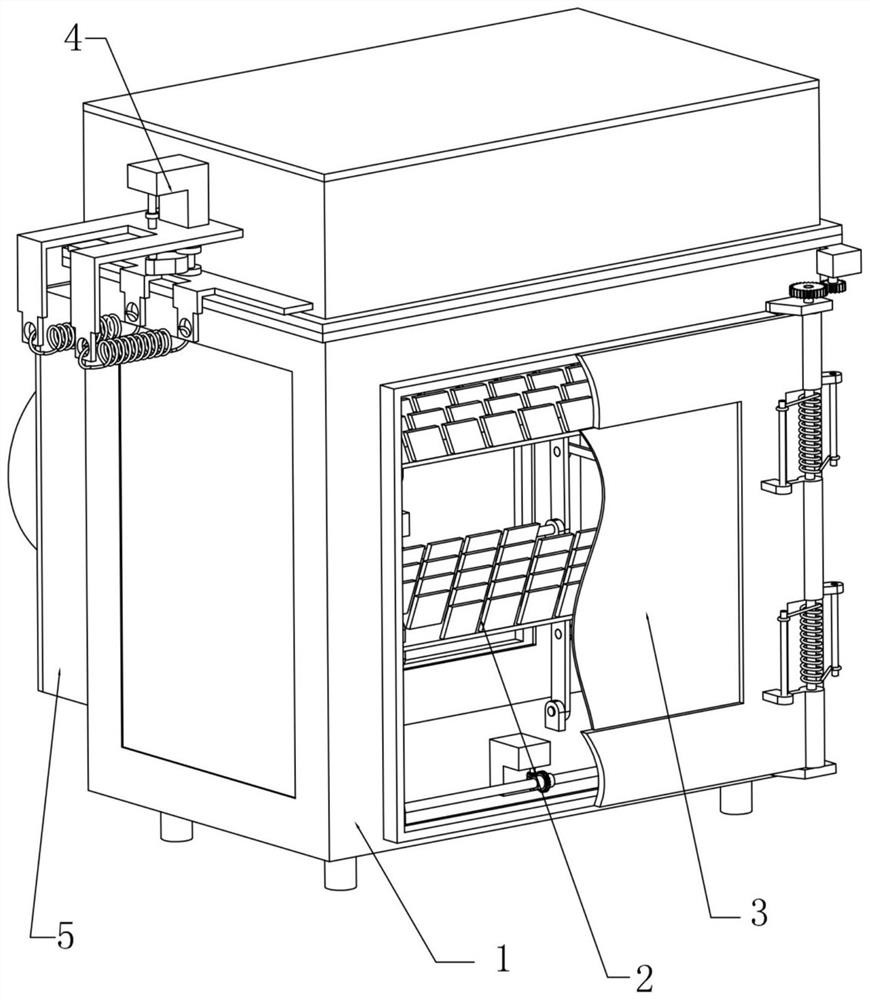

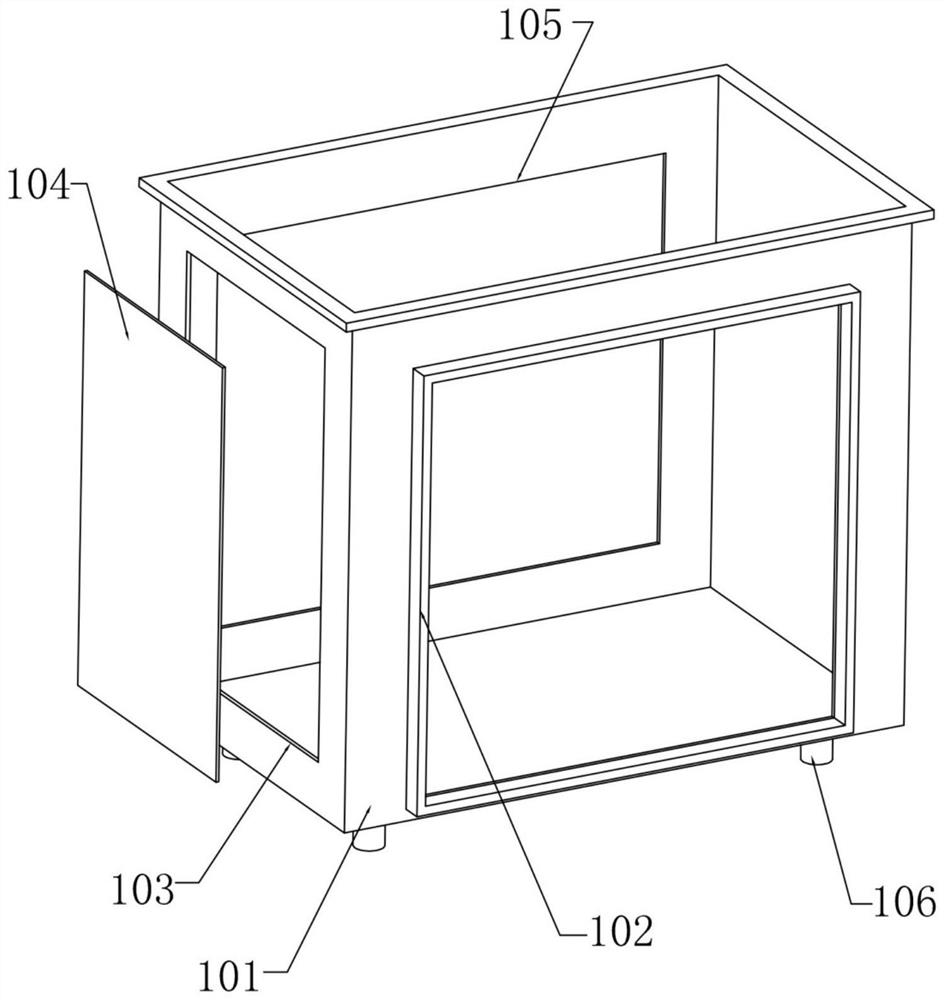

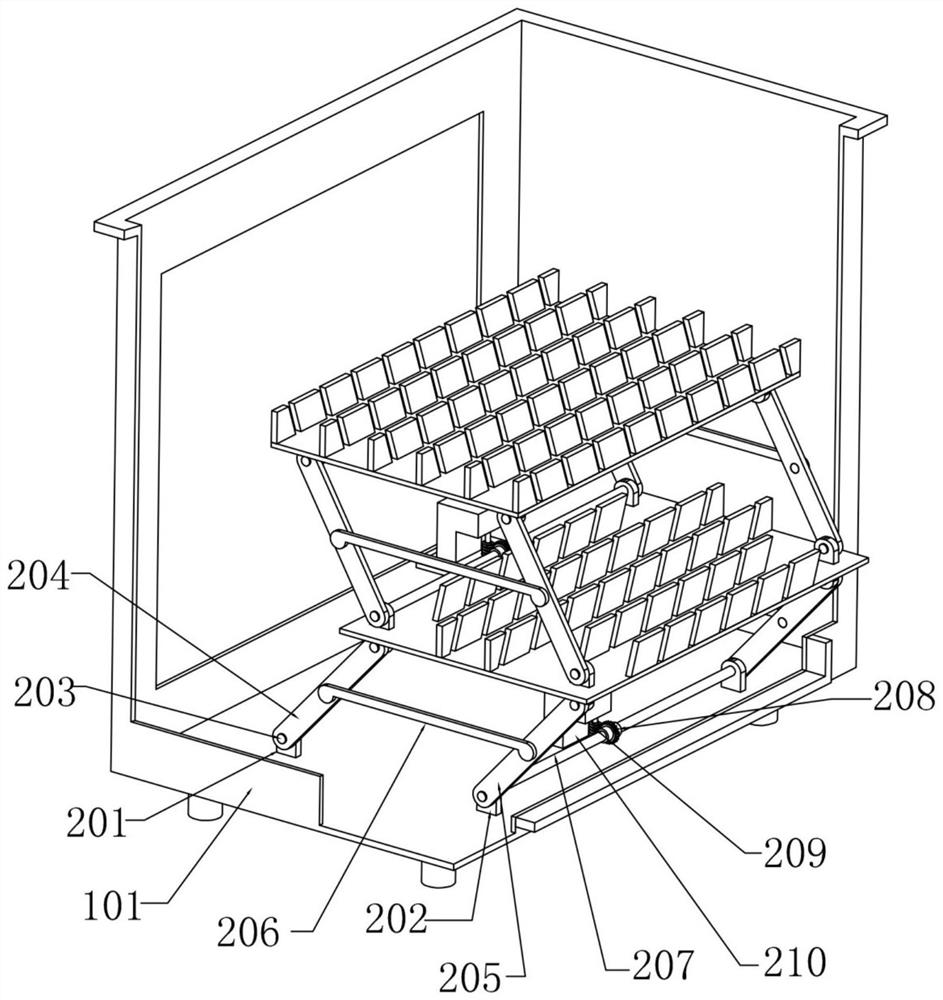

[0046] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 Shown is a drying box for the production of electronic products that is convenient to be placed in batches. The main box 101 in the box assembly 1 is the main body for placement, and is a cavity structure with an open top. The main front of the main box 101 is provided with a main box 102, the main rear of the main box body 101 is provided with a heat dissipation installation position 105, the lower substrate 211 and the upper layer plate 223 of the multi-layer clamping assembly 2 are arranged in the inner cavity of the main box body 101, and the door leaf 301 of the door leaf assembly 3 is located The front end of the main box opening 102, the drying box 401 in the drying assembly 4 is fixedly installed on the top of the main box 101, the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com