Mechanical part fault diagnosis method based on SVD and VMD

A fault diagnosis and mechanical technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as information omission, impact of decomposition results, failure to consider the correlation between modal components and original signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

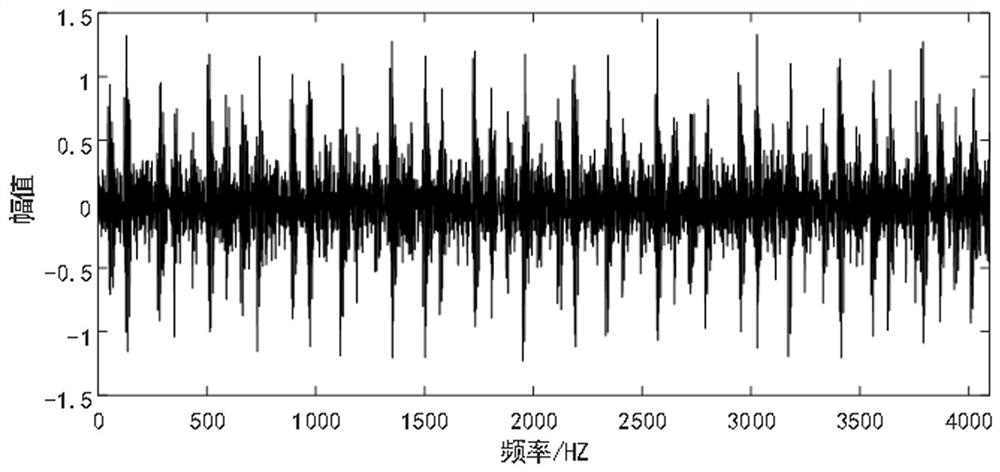

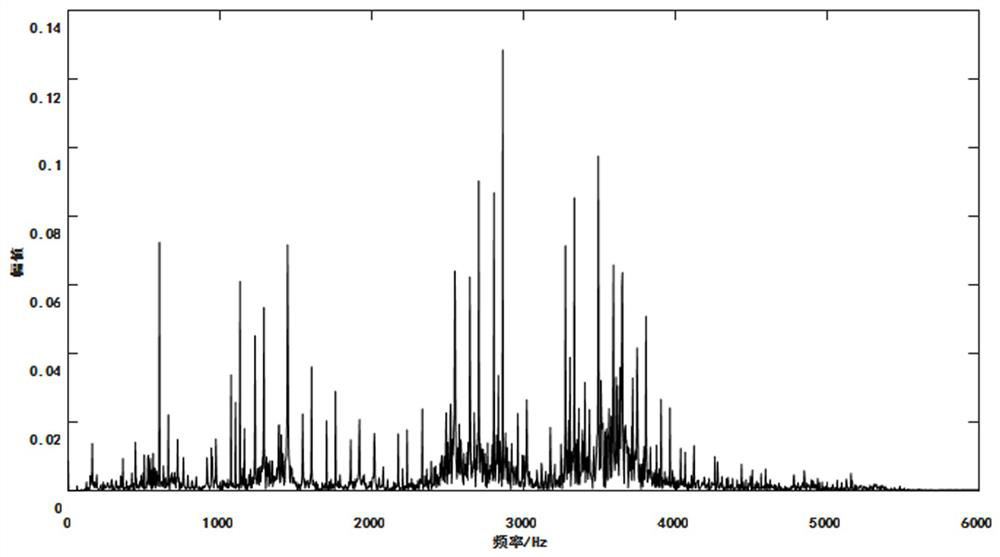

[0070] In the embodiment, the mechanical part for fault diagnosis is a bearing, the bearing type is 6205-2RS deep groove ball bearing, the number of rolling elements is 9, the contact angle is 65°, the diameter of the rolling elements is 7.94004mm, the pitch diameter is 39.04mm, the inside and outside of the bearing The diameter and thickness are 25mm, 52mm and 15mm respectively. The bearing experimental device of the embodiment includes a torque sensor / decoder, a motor, a power tester and an electronic controller. The fault type of the bearing is local slight damage, which is mainly formed by artificial spark pitting. The damage size is 0.18mm*0.28mm. The vibration signal of the bearing is measured by the acceleration sensor installed on the induction motor. The signal sampling frequency is 12000Hz, the motor speed is 1750r / min, and the number of data points is 4096.

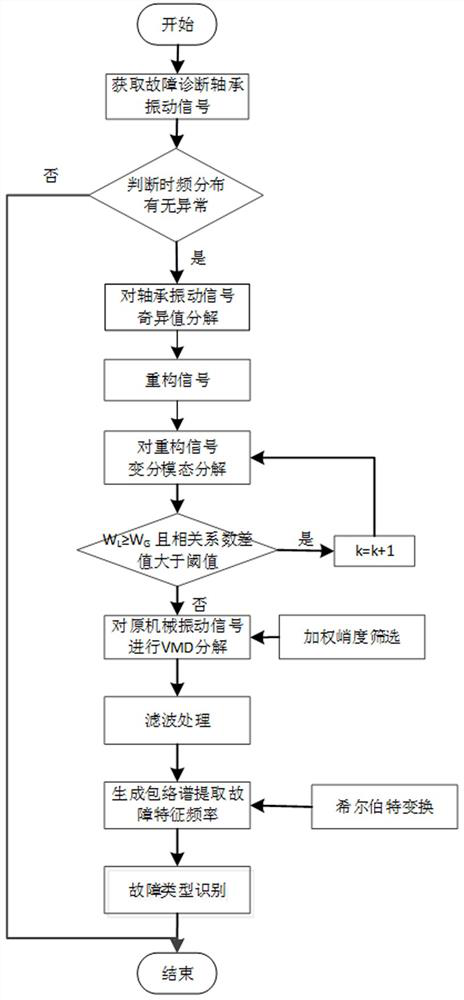

[0071] Such as figure 1 As shown, the fault diagnosis method of mechanical parts based on SVD and VMD incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com