Multi-material 3D printing method and micro-flow extrusion type printer based on multi-material 3D printing method

A 3D printing, multi-material technology, applied in the field of 3D printing, can solve problems such as printing delay error, material delay, printing deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

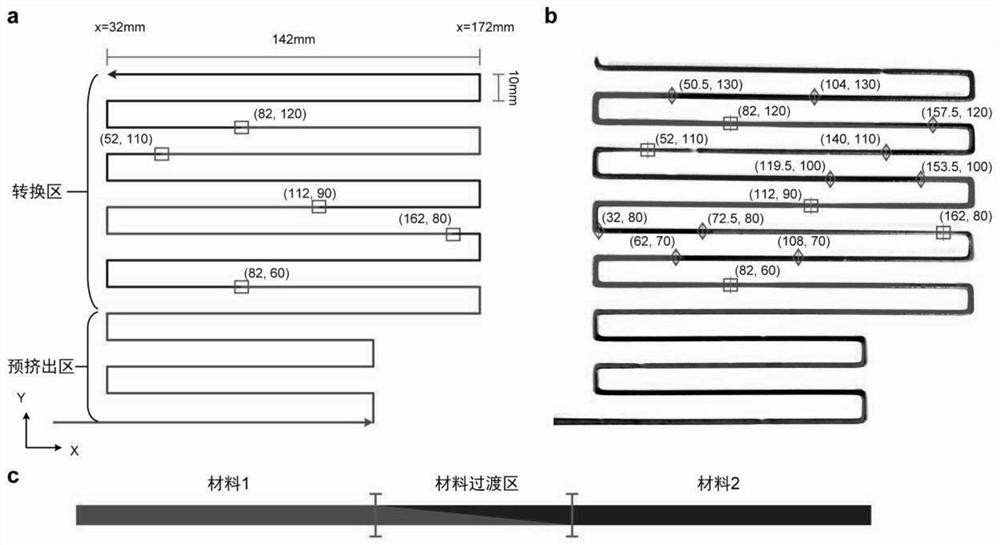

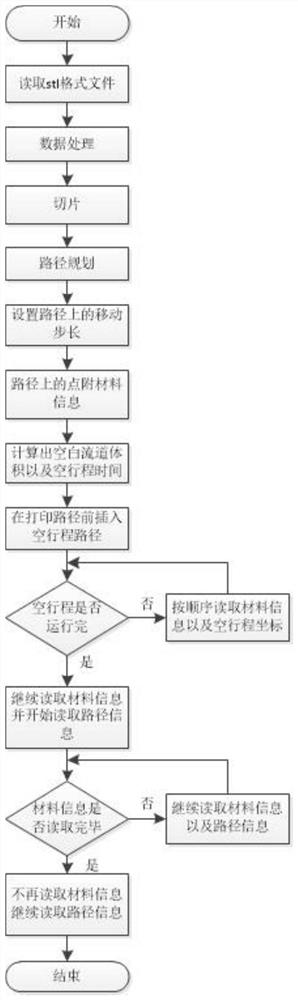

[0032] The present invention is a multi-material 3D printing method (method for short, see Figure 2-3 ), including the following:

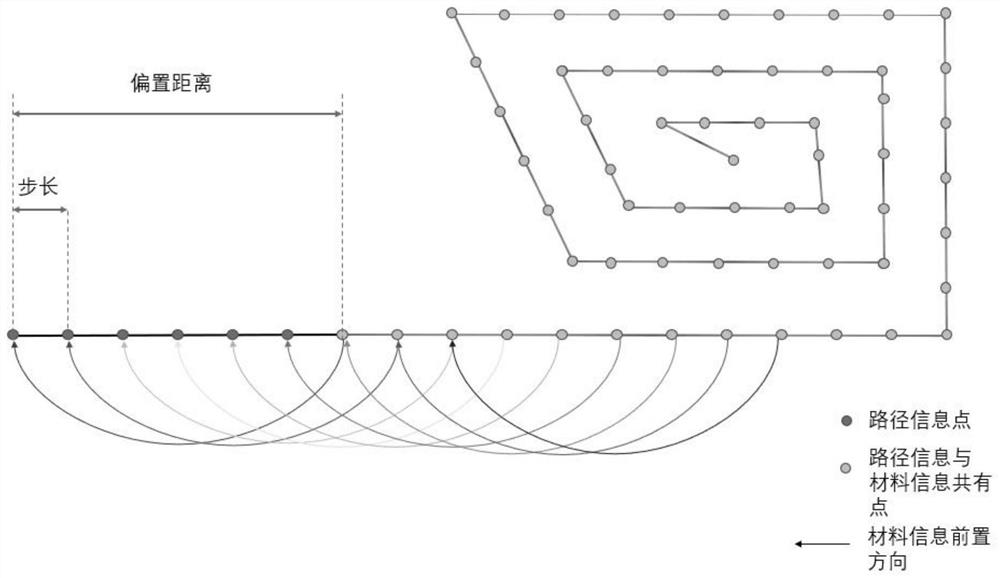

[0033] 1. Read the stl format file of the object to be printed, perform data processing on the stl format file, and then slice the processed object to be printed; plan the path of the print head according to the structure of the object to be printed, and obtain the path information of the print head , that is, the path information of the forming platform; set the moving step on the path, and add material information to the points on the path; the moving step refers to the distance that the print nozzle moves each time, and set the movement according to the color change after mixing multiple materials step si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com