Black iron sand spraying device for mud blank slices of dark-red enameled pottery

A technology of purple sand pot and purple sand mud, applied in ceramic molding machines, manufacturing tools, etc., can solve the problem of incomplete mixing of purple sand mud and black sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

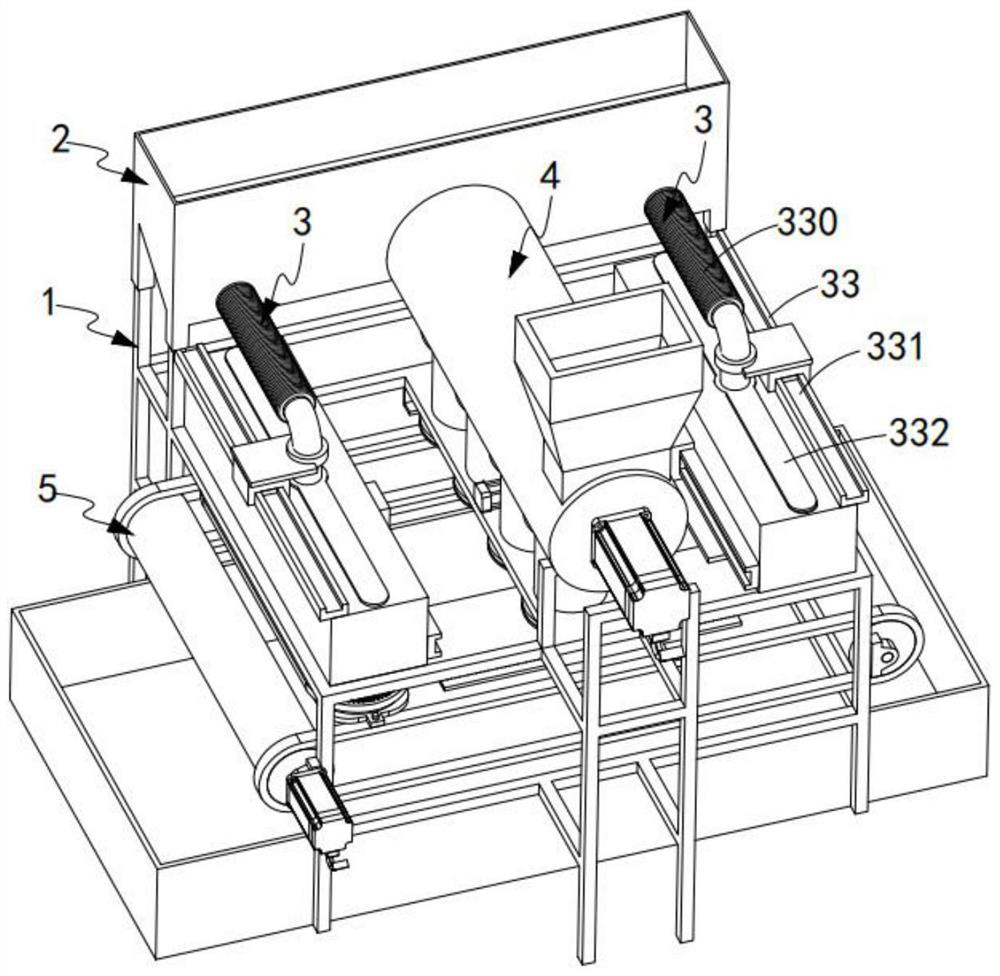

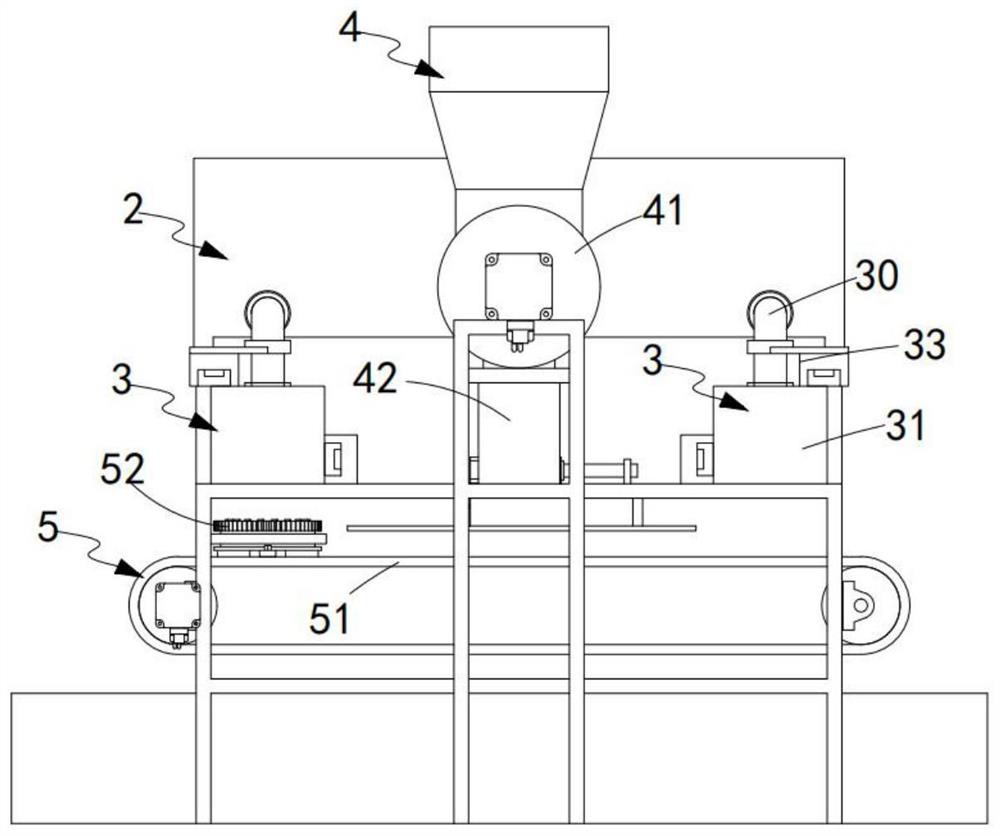

[0072] Such as Figure 1 to Figure 12 As shown in the figure, a device for sprinkling black iron sand on clay pot slices, including:

[0073] Rack 1;

[0074] Black sand hopper 2, the black sand hopper 2 is installed on the top of the frame 1, black sand is stored in the black sand hopper 2;

[0075] Sand distributors 3, two sets of sand distributors 3 are respectively mounted on both ends of the frame 1, the sand distributors 3 communicate with the bottom of the black sand hopper 2 through a material pipe 30, the sand distributors 3 for distributing the black sand in the black sand hopper 2;

[0076] Mud billet extruder 4, described mud billet extruder 4 is installed between two groups of described sand distributors 3, and this mud billet extruder 4 evenly extrudes several cylindrical purple sand mud billets downwards ;

[0077] Material receiving conveyor 5, described material receiving conveyor 5 is installed below described sand cloth device 3 and described mud base ex...

Embodiment approach

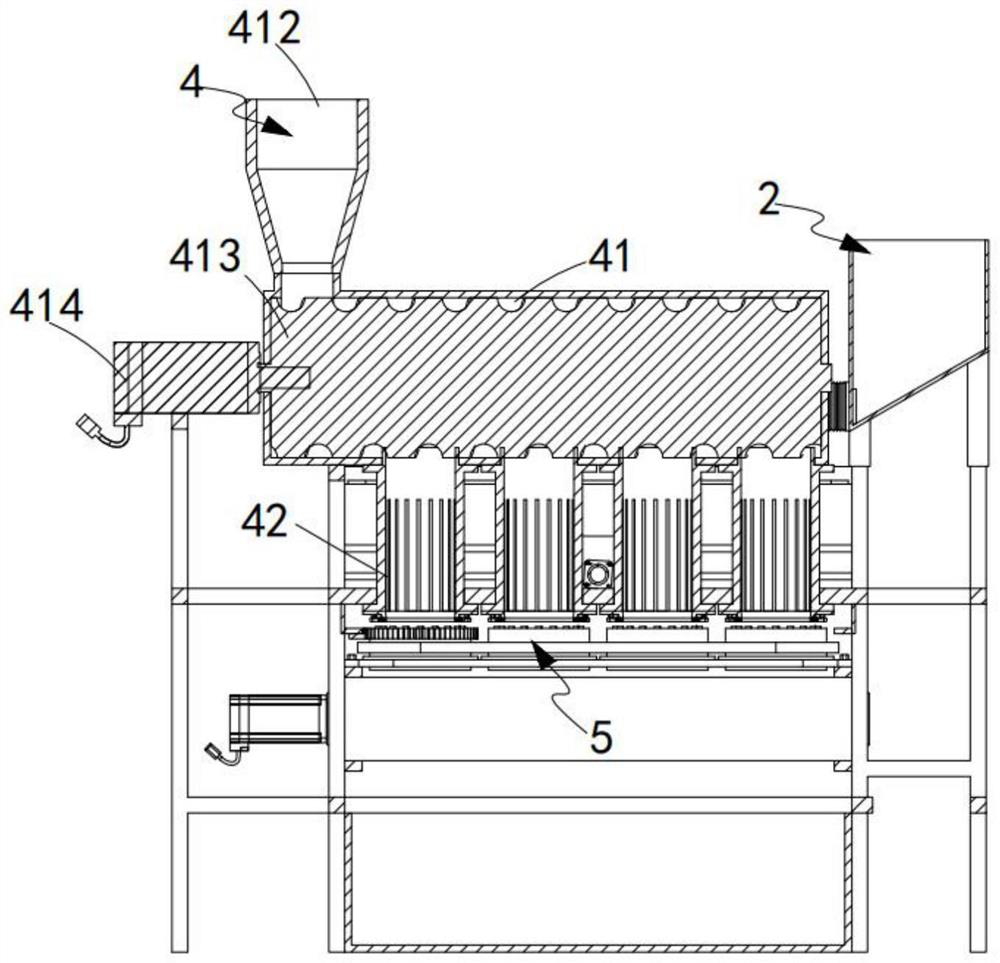

[0089] As a preferred embodiment, the mud extruder 4 includes:

[0090] Extrusion assembly 41, said extrusion assembly 41 spirally extrudes purple sand mud;

[0091] Forming cylinder 42, a plurality of said forming cylinders 42 are equidistantly arranged along the length direction of said screw extruder 411, and said forming cylinder 42 is communicated with said screw extruder 411, and said forming cylinder 42 is connected with said mud base The rubbing drum 52 is provided in one-to-one correspondence; and

[0092] Kneading and cutting assembly 43, while said kneading and cutting assembly 43 kneads the purple sand mud material in said forming cylinder 42, cuts the purple sand mud blank output from said forming cylinder 42, and the output purple sand mud blank falls on the corresponding The mud base is rubbed into the barrel 52.

[0093] Wherein, the extrusion assembly 41 includes:

[0094] Extrusion pump casing 411, the top of the extrusion pump casing 411 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com