Hydrolysis-impurity removal device and method for fruit-and-vegetable waste slurry

A fruit and vegetable waste and slurry technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as easy to block screens, affect normal production of projects, and perishable fruit and vegetable waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail. It should be understood that the following examples are only used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the contents of the present invention still belong to protection scope of the present invention.

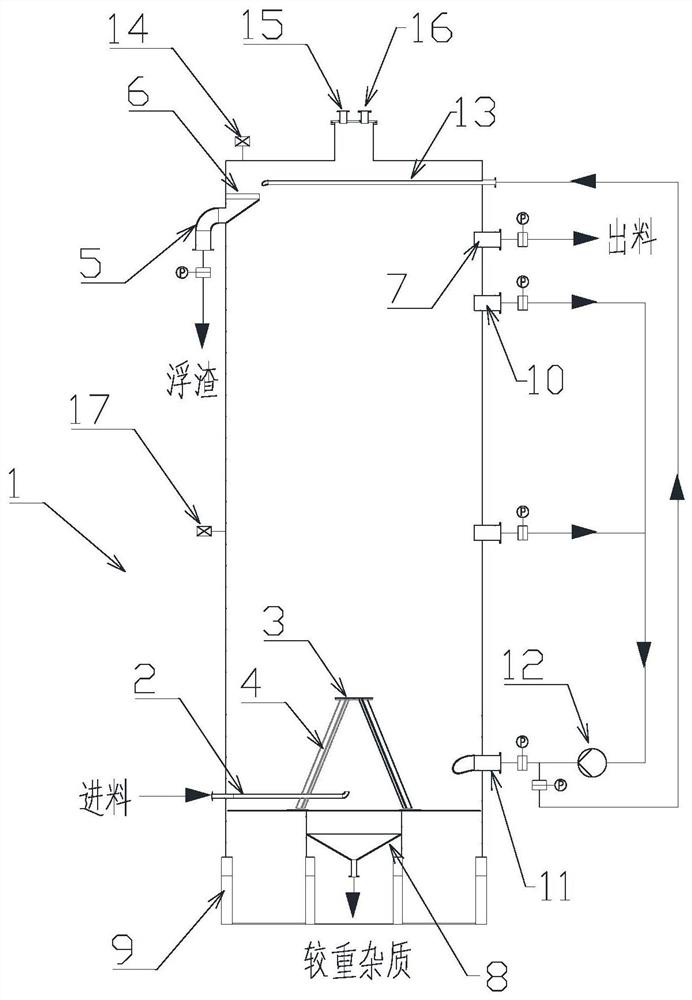

[0027] figure 1 A schematic diagram of a hydrolysis-impurity removal device for fruit and vegetable waste slurry of the present invention is shown. Depend on figure 1 As shown, the hydrolysis-impurity removal device includes a hydrolysis impurity removal tank 1, the bottom end of the hydrolysis impurity removal tank 1 is placed on the base 9, and the lower end of the side wall is provided with a feed pipe 2 horizontally inserted into the center of the tank body , the outlet of the feed pipe 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap