Light fabricated steel structure building

A prefabricated, steel structure technology, applied in the direction of construction, building construction, etc., can solve problems such as cumbersome operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

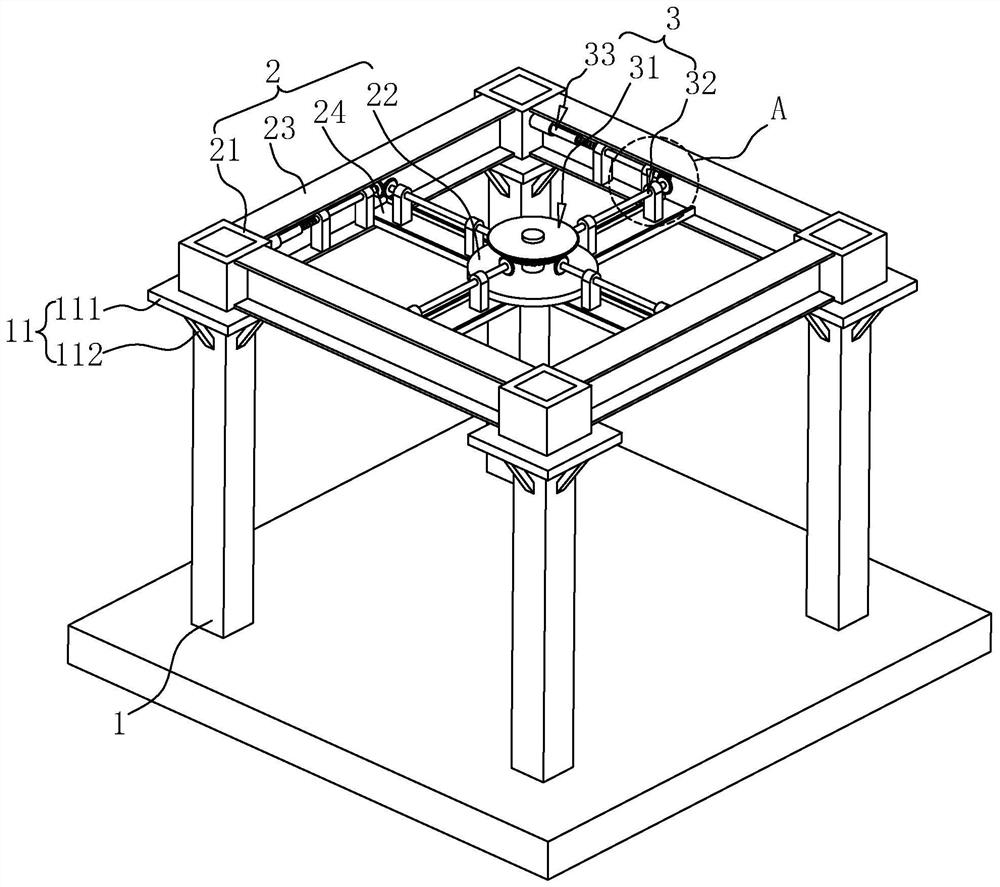

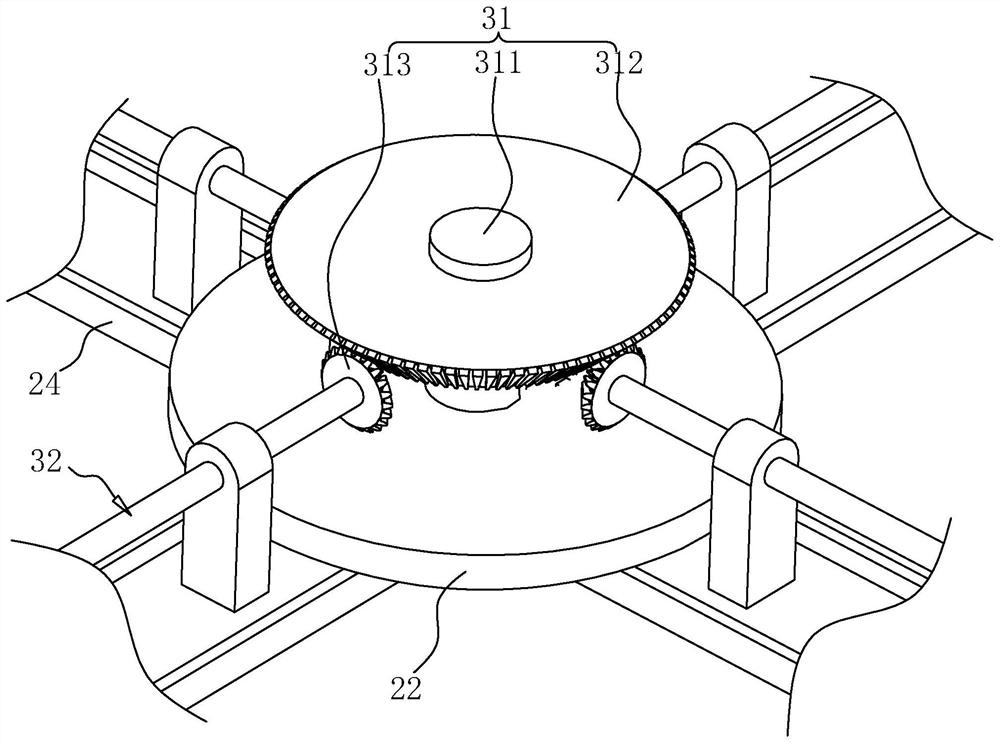

[0039] Example discloses a prefabricated lightweight steel construction of the present application. Refer figure 1 The building structure 1 and comprises a plurality of pillars disposed upright on the crossbeam 12, wherein, in the present embodiment, the number of the column 1 is provided specifically four, four columns 1 arranged in the vertical direction, and was a rectangular arrangement, the bottom end of the column 1 may be fixedly mounted to the foundation, mounting the column 1 is the prior art, it is not repeated here.

[0040] Column 1 for supplying supporting crossbeam 2, specifically, the top of the column 1 is provided with supporting platforms 11, wherein the supporting platform 11 comprises a supporting plate 111 and the reinforcing bars 112. Supporting plate 111 disposed in the horizontal direction, the outer edge contour shape through the upper supporting plate 111 is provided with a socket hole, the hole socket contour shape adapted to the pillar 1, via the suppor...

Embodiment 2

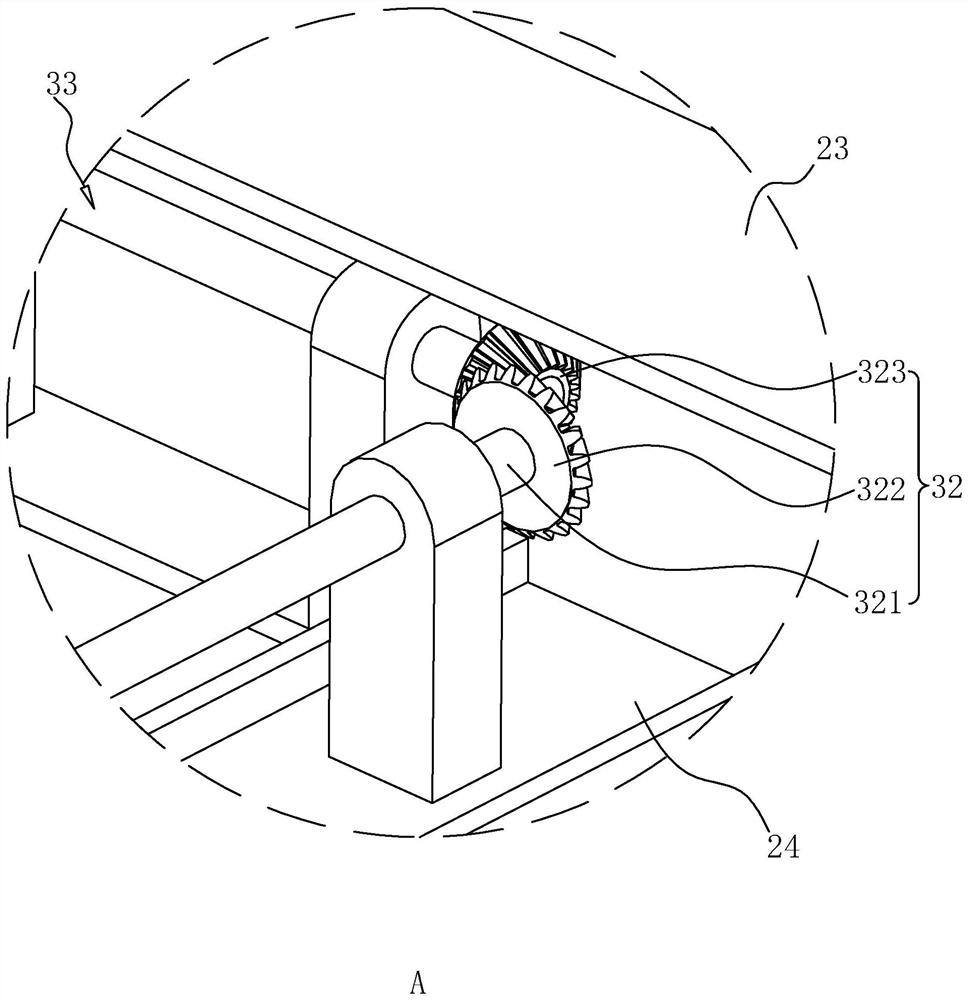

[0059] Refer Figure 5 The present embodiment is different from Embodiment 1 in that, the building structure further comprises an input shaft 311 adjacent to the engaging component 4. In particular, the engaging component 4 is disposed on the mounting platform 22, with the engaging component 4 to lock the input shaft 311 is fixed to reduce the portion of the socket 21 and the lock pillar 1 is engaged, the input shaft 311 and the possibility of rattling of loose offset.

[0060] Specifically, the fastening assembly 4 includes a first clamping portion 41 and the second clamping portion 42, the first clamping portion 41 and the second holding portion 42 are connected to slip crossbeam 2, wherein the mounting platform 22 outward from the top of the recess 221 is provided with a chute, the chute 221 adjacent the input shaft 311.

[0061] Further, the first clamping portion 41 includes a first connecting arm 411, a second connecting arm 412, and a first arcuate clamp arm 413, connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com