Anti-seismic combined aluminum alloy formwork

A kind of aluminum alloy formwork, anti-seismic technology, applied in the direction of formwork/formwork member, formwork/formwork/work frame, spring/shock absorber, etc., can solve the problem of difficult to have both seismic performance, damage and deformation of hard-connected structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

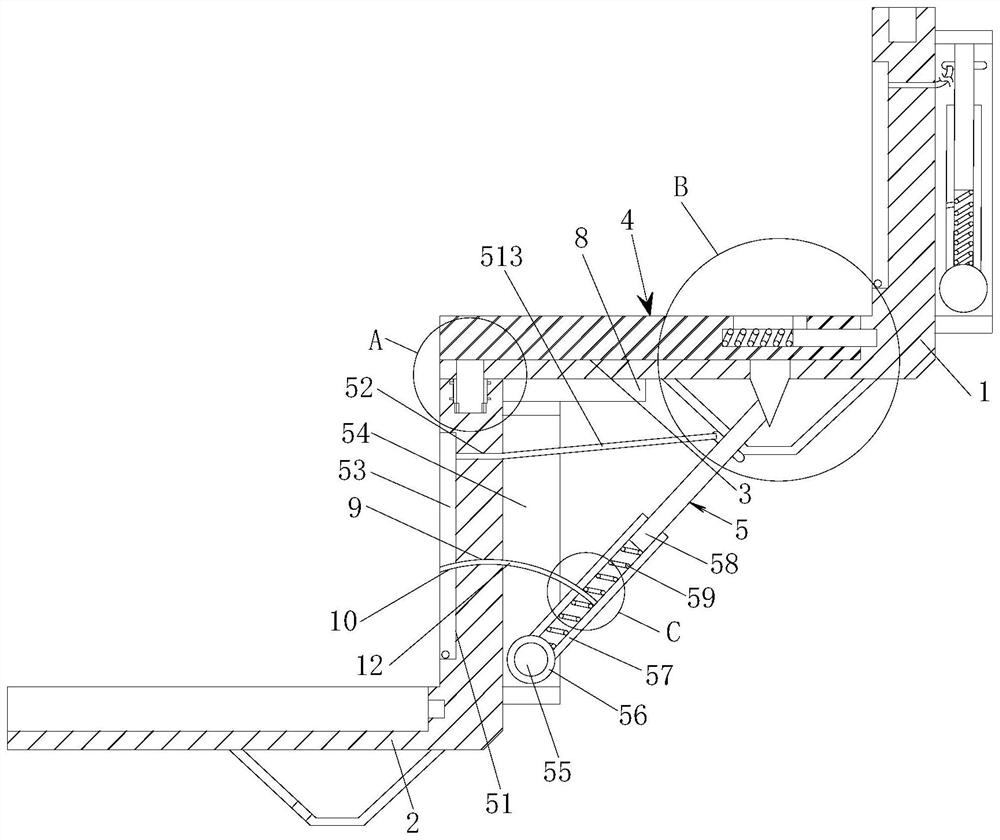

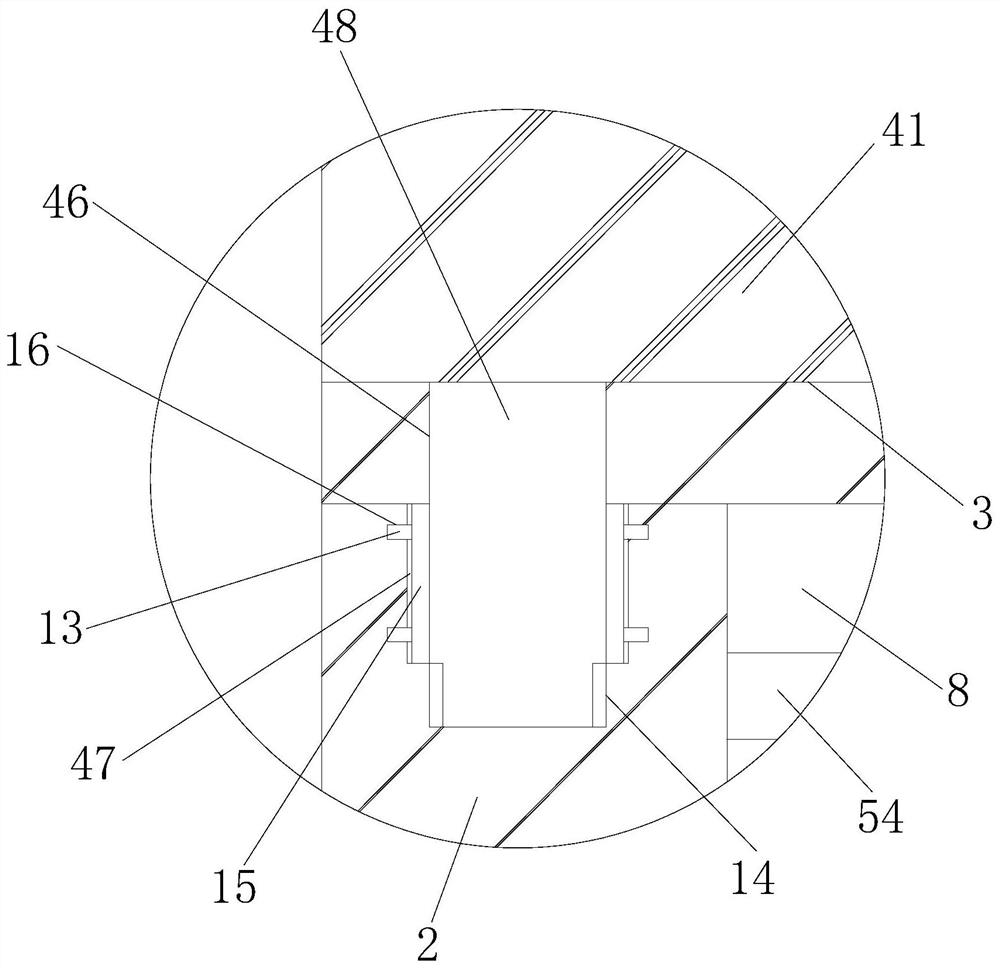

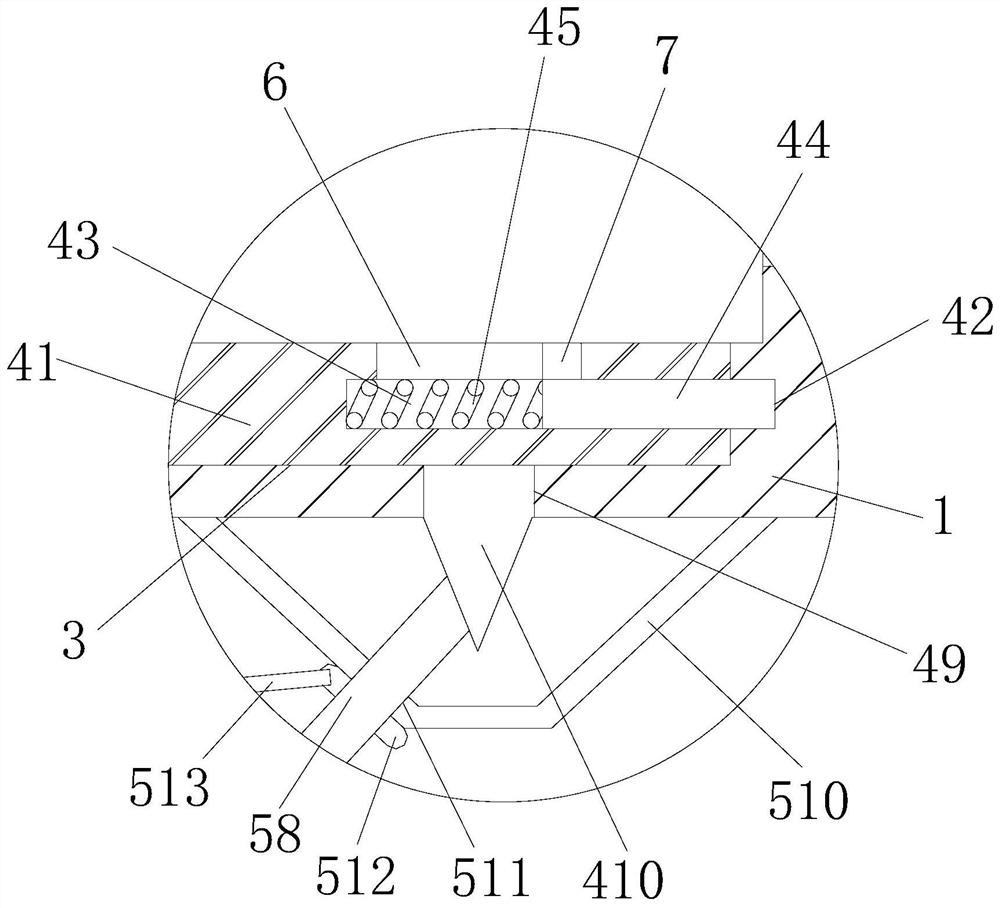

[0022] see Figure 1-4 , the present invention provides a technical solution: an anti-seismic composite aluminum alloy formwork, comprising a first formwork 1 and a second formwork 2, the first formwork 1 and the second formwork 2 are stacked up and down in a staircase shape, the first formwork 1 and the second formwork 2 The cross-sections of the two templates 2 are both right-angled, the left end of the lower surface of the first template 1 is in contact with the top of the vertical plate of the second template 2, and slots are provided on the upper surfaces of the horizontal plates of the first template 1 and the second template 2 3. A positioning mechanism 4 is provided in the slot 3 of the first template 1, and an anti-vibration mechanism 5 is provided on the vertical plates of the first template 1 and the second template 2.

[0023] The positioning mechanism 4 includes a positioning plate 41, a positioning hole 42, a positioning groove 43, a positioning column 44, a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com