Construction Method of Setting Inclined Ring Joints to Improve Seismic Performance of Shield Segment Structural Joints

A technology of shield segments and anti-seismic performance, which is applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve problems such as shear failure of connecting bolt joints, deformation of segments, loss of life and property, etc., to achieve good economy and improve Seismic safety performance, effect of improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

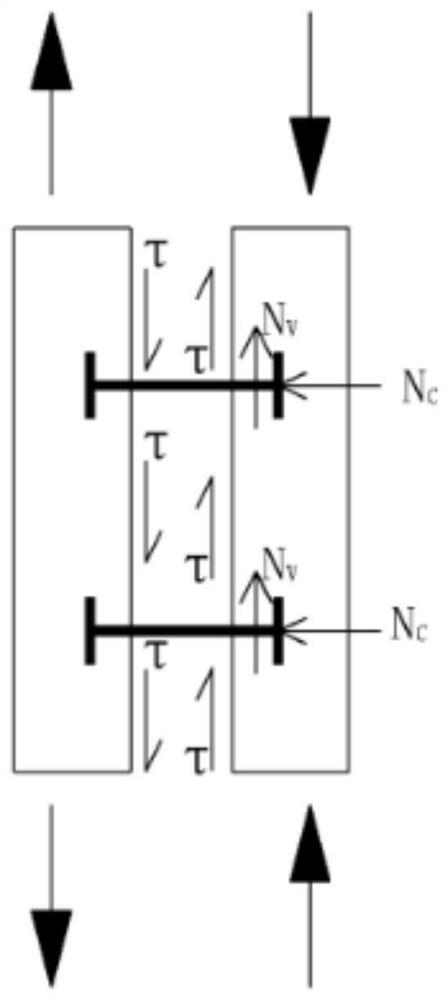

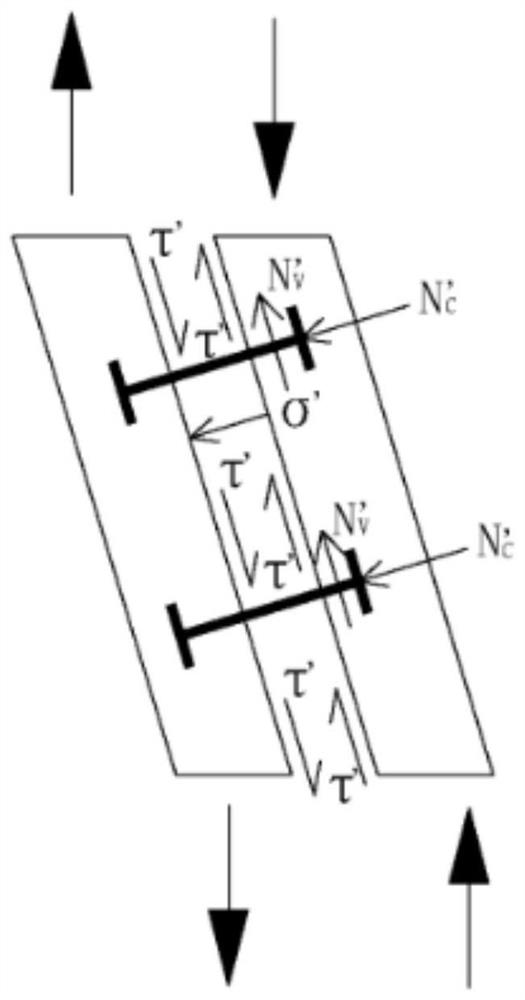

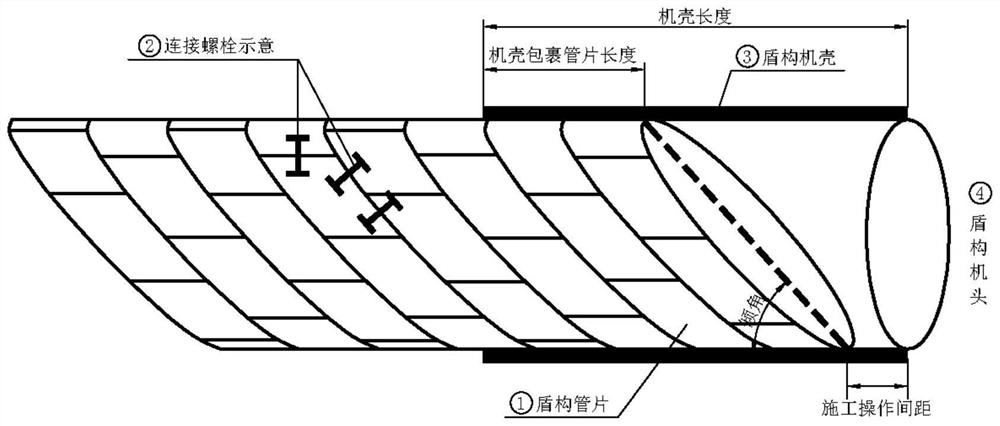

[0025] Such as Figure 3 to Figure 6 As shown, the construction method of setting inclined annular joints to improve the seismic performance of the structural joints of shield tunneling segments includes several prefabricated shield tunneling segments 1 .

[0026] Among them, each prefabricated shield segment 1 is arc-shaped, and is a space surrounded by two surfaces parallel to each other and inclined relative to the extension direction of the underground shield tunnel in the underground shield tunnel. After the plane is unfolded, it is a parallelogram ; Construction steps are as follows:

[0027] Step 1, prefabricating the shield machine 3; the casing length of the shield machine 3 matches the inclination angle of each prefabricated shield segment 1 relative to the extension direction of the underground shield tunnel;

[0028] Step 2. Splice the first ring prefabricated shield segment 1; excavate to the position where the first ring prefabricated shield segment 1 is set, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com