Novel locknut assembly special for railway

A lock nut, a new type of technology, applied to nuts, threaded fasteners, screws, etc., can solve the problem that the nut cannot be used for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

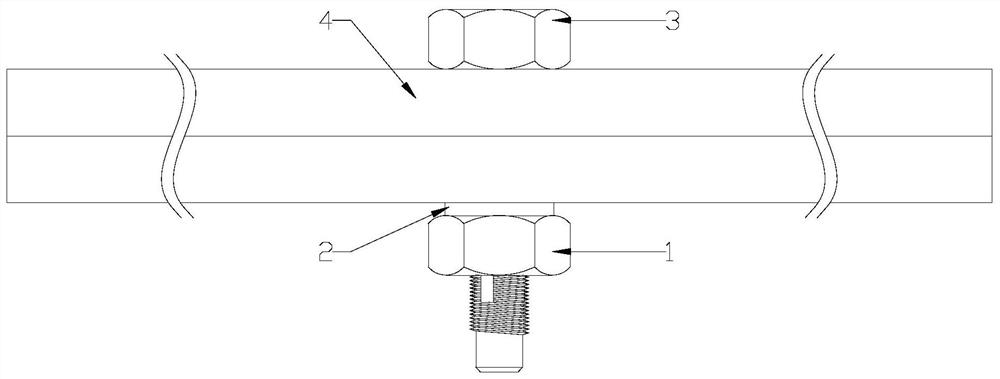

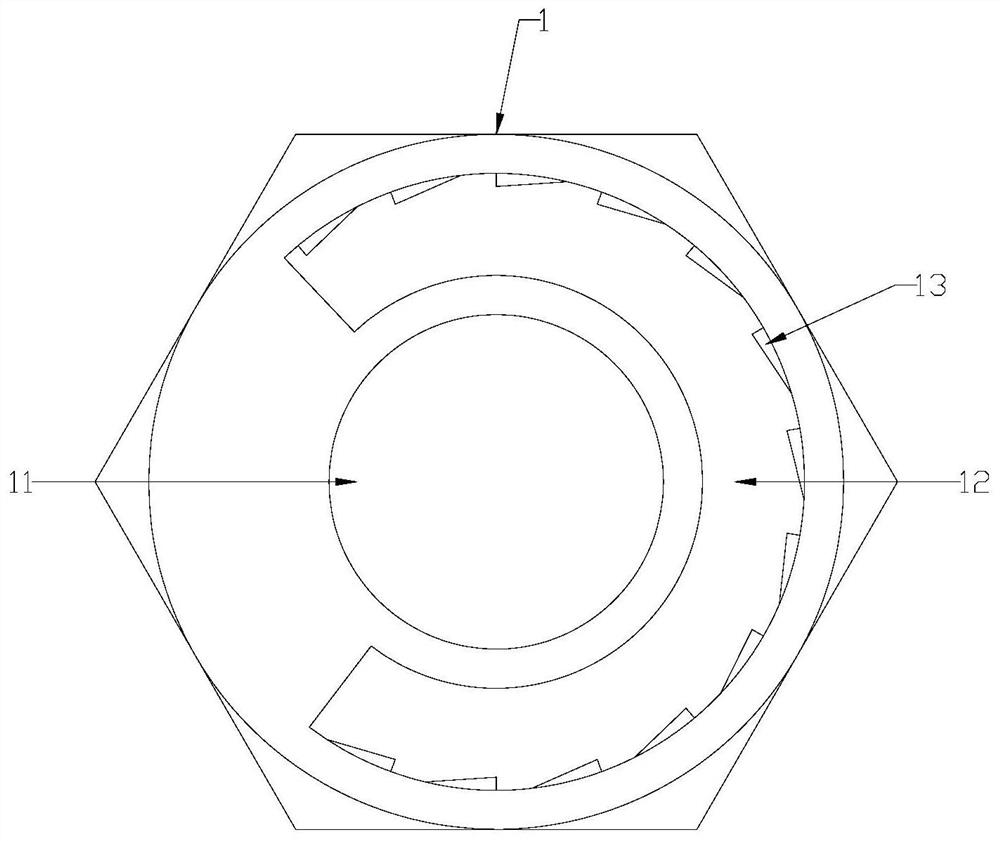

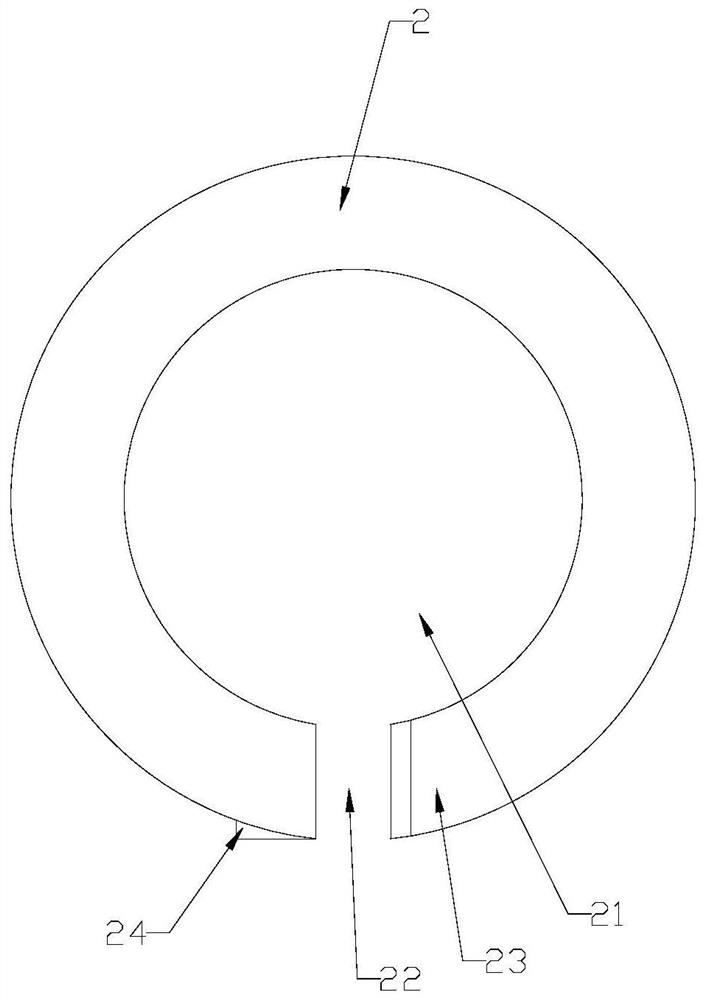

[0021] refer to Figure 1 to Figure 4 , the present invention is a new type of anti-loosening nut assembly for railways, comprising a nut 1 and a spring washer 2, the side of the spring washer 2 is provided with a gap 22 communicating with the through hole 21 of the internal sheet body and forms two free ends respectively Ends 23 inclined upwards and downwards, one of the ends 23 is provided with a protruding strip 24 extending outwards along its inclination direction, and the nut 1 is provided with a threaded hole 11 around the threaded hole. The arc-shaped through-groove 12 through which the protruding part 24 passes.

[0022] The outer wall of the protruding part 24 is provided with a first protruding tooth 25, and the inner wall of the arc-shaped through groove 12 is provided with a plurality of second protruding teeth 13 matched with the first protruding tooth 25. 1 When the nut 1 rotates in the direction of loosening, the first protruding tooth 25 and the second protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com