PLC (Programmable Logic Controller) system for intelligent control of major engineering

An intelligent control and engineering technology, applied in the field of PLC system, can solve problems such as wiring errors, fire, I/O port misconnection and short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

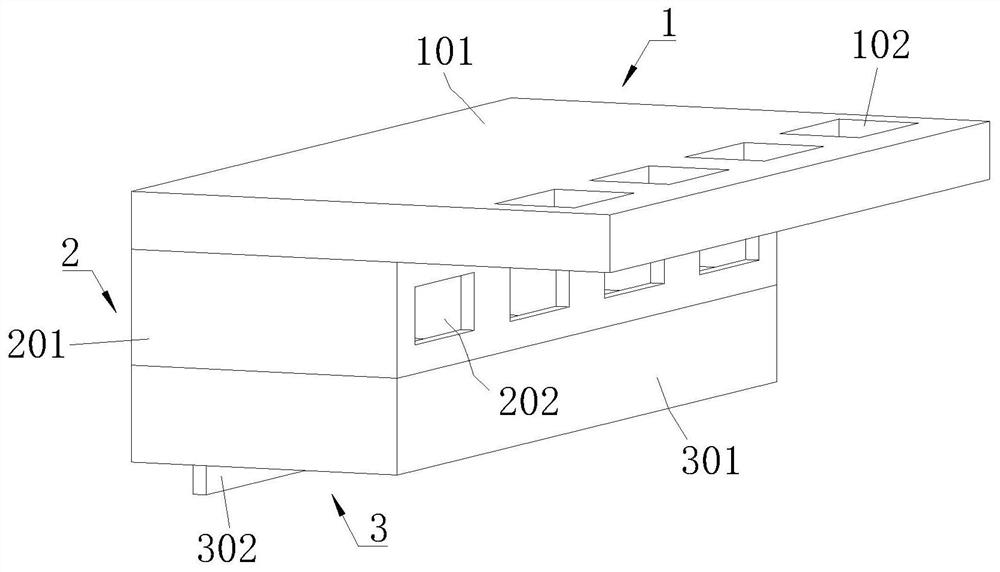

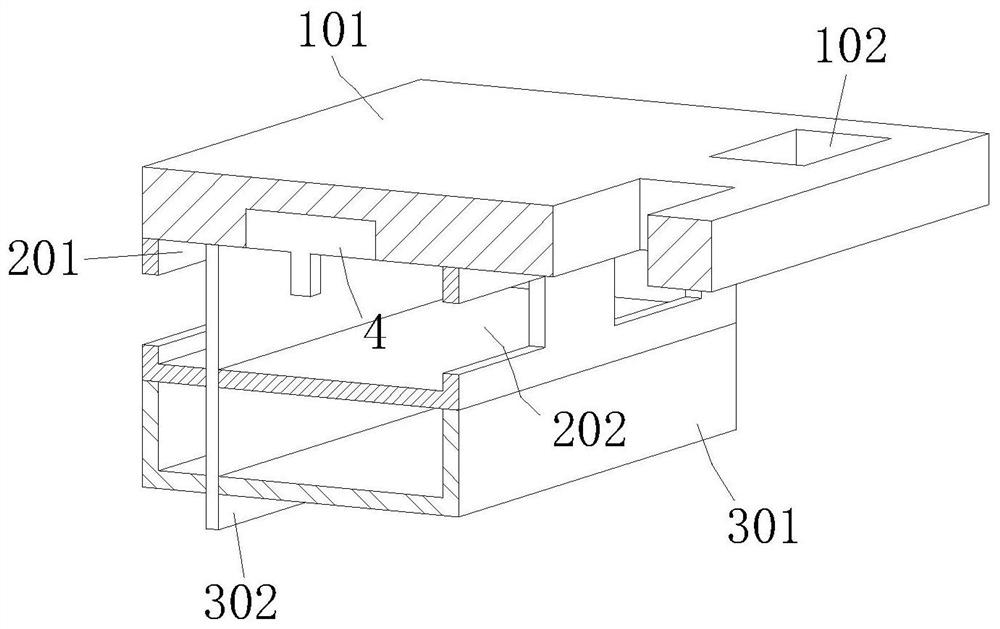

[0038] Specific embodiment one: please refer to Figure 1-11 The wiring device, the wiring includes a pressing unit 1, a wiring unit 2, an on-off unit 3 and a control unit 4.

[0039] The pressing unit 1 includes a pressing plate 101 and a plurality of pressing holes 102 , and the pressing holes 102 are opened on the right side of the pressing plate 101 and pass through the pressing plate 101 .

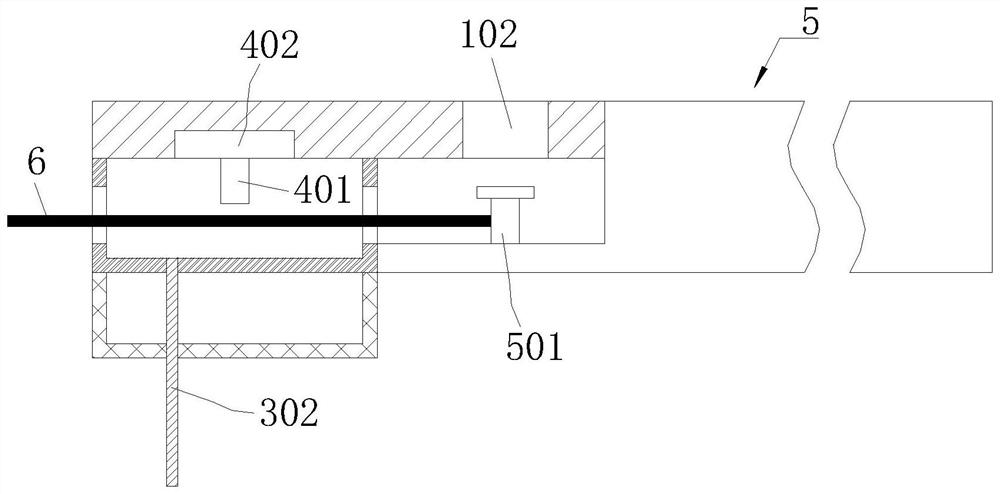

[0040] The wiring unit 2 includes a junction box 201 and a plurality of wiring through holes 202 . A plurality of connection holes 202 run through the left and right side walls of the junction box 201 . The upper end of the junction box 201 is detachably connected to the lower end on the left side of the pressing plate 101, and the pressing holes 102 correspond to the wiring through holes 202 one by one, and each pressing hole 102 and the corresponding wiring through hole 202 are located on the same axis.

[0041] Each wire 6 can only be electrically connected to the terminal 501 of...

specific Embodiment 2

[0057] Embodiment 2: Different from Embodiment 1, the on-off assembly 302 includes more than three baffle plates 302-2 and one activation plate 302-1.

[0058] The structure of the baffle 302-2 is consistent with that in the first embodiment.

[0059] The number of lower outlets 303 and moving slots 304 provided on the lower side of the on-off box 301 is consistent with the number of baffles 302-2.

[0060] The connection relationship between the baffle plate 302-2, the lower outlet 303 and the moving slot 304 is the same as that in the first embodiment.

[0061] The sequential opening of multiple wiring through holes 202 can be realized, which provides guarantee for the wiring operation of the complex PLC system.

specific Embodiment 3

[0062] Specific embodiment three: different from specific embodiment one, the on-off assembly 302 includes a plurality of iron plates, and the lower end of the on-off box 301 is provided with a corresponding number of outlets, the width of the outlets is greater than the width of the iron plates, and the number of iron plates is related to the wiring through holes. 202 correspondence.

[0063] The upper end of each wiring through hole 202 is provided with an electromagnet, the electromagnet is electrically connected with the sensing module 402, a controller is arranged between the electromagnet and the sensing module 402, the controller is electrically connected with the sensing probe 401, and the electromagnet is connected with the sensing module 402. Iron plate magnetic connection.

[0064] When the induction probe 401 senses that the measured electric wire 6 is connected correctly, the controller controls the electromagnet in the next sequence to be de-energized, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com