Wave-absorbing surface with low profile and low incidence angle sensitivity and manufacturing process thereof

A technology of incident angle and sensitivity, applied in the direction of electrical components, antennas, etc., can solve the problems of incident angle sensitivity and high profile of absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

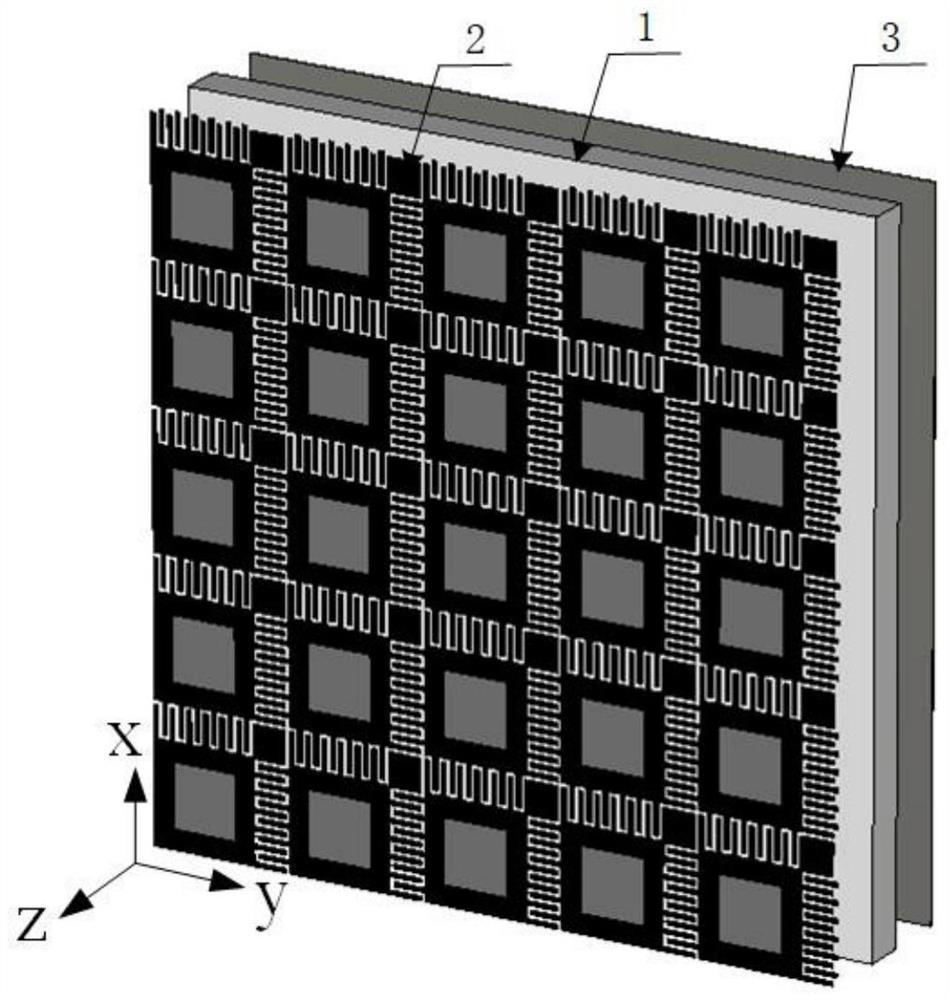

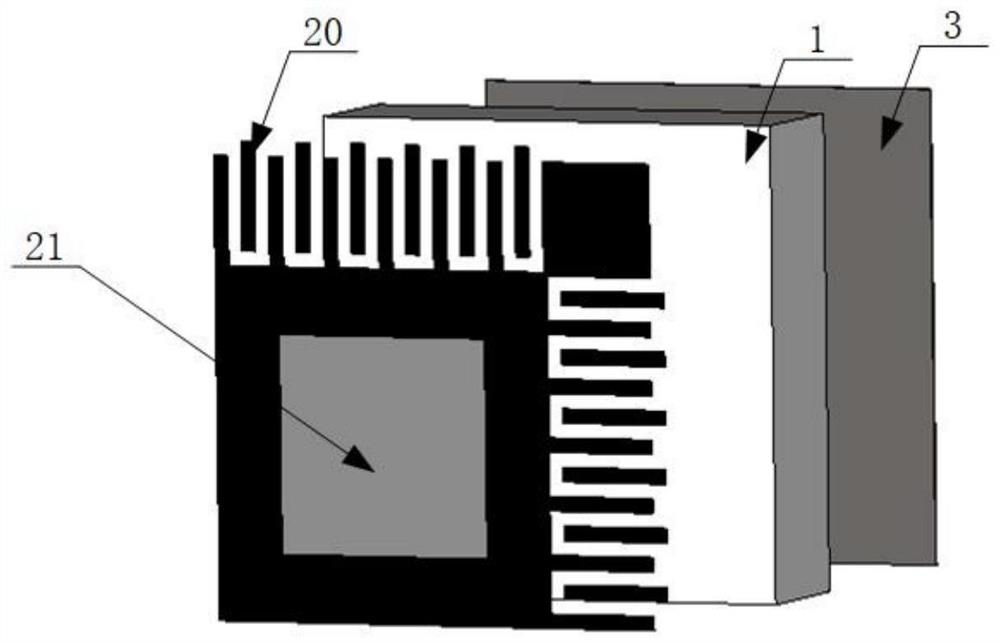

[0034] Such as Figure 1-4 As shown, the wave-absorbing surface with low profile and low incidence angle sensitivity of the present invention includes a dielectric substrate 1 , a two-dimensional planar periodic array 2 printed on the front of the dielectric substrate 1 , and a metal floor 3 printed on the back of the dielectric substrate 1 . The overall structure from top to bottom is a two-dimensional planar periodic array 2, a dielectric substrate 1, and a metal floor 3.

[0035] The two-dimensional planar periodic array (2) is formed by periodic arrangement of lossy frequency selection units along two directions of x-axis and y-axis.

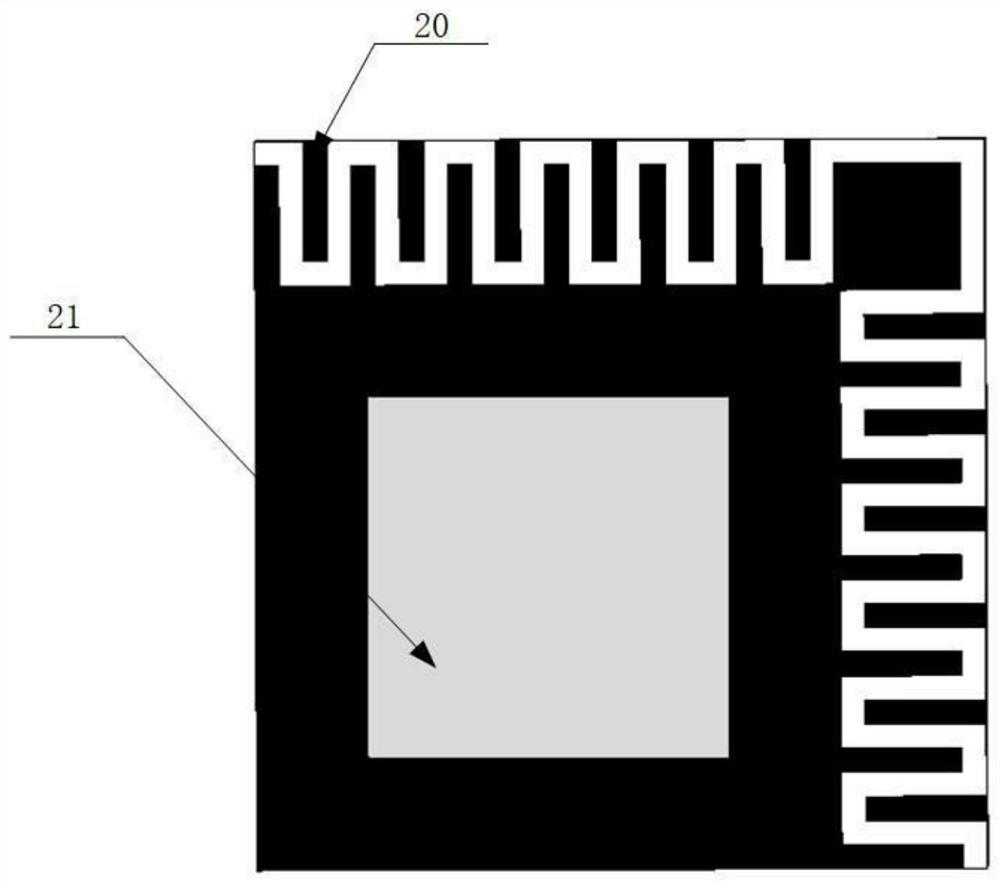

[0036] The lossy frequency selective unit of the two-dimensional planar periodic array 2 is a nested structure composed of an edge interdigitated resistive square ring patch and a metal square patch, and the metal square patch is embedded in the resistive square patch. The area on the lower left of the ring patch.

[0037] The edge of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com