Tunnel construction man-machine positioning system and method

A technology of tunnel construction and positioning system, which is applied in the fields of earthwork drilling, computer parts, and services based on location information, can solve the problems of cumbersome moving and positioning base stations, restricting the development of automatic construction, and requiring high technical level of positioning and surveying personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

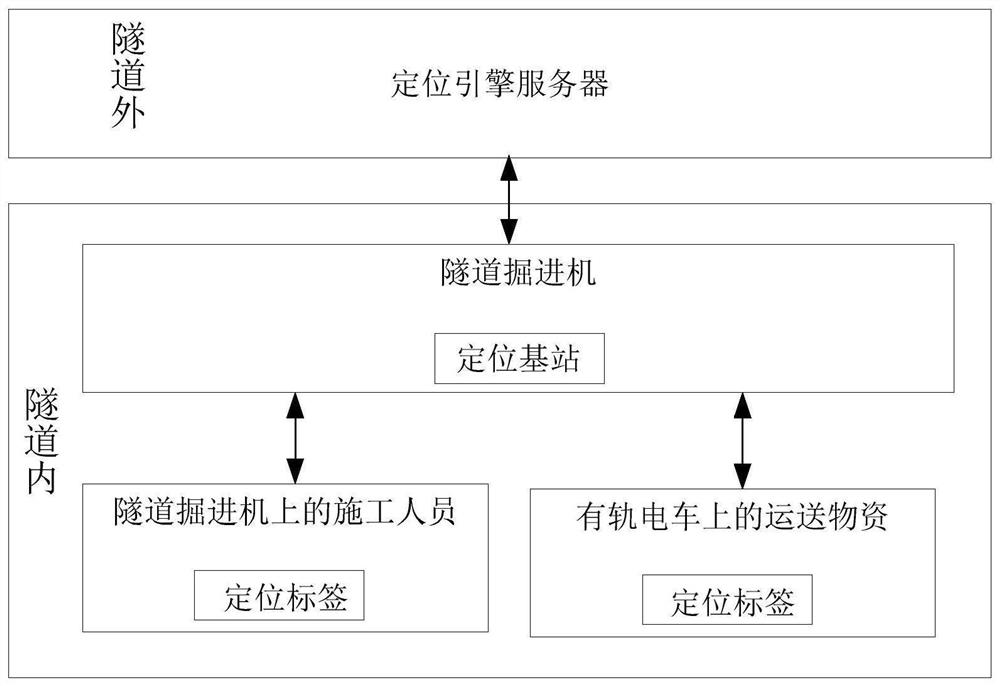

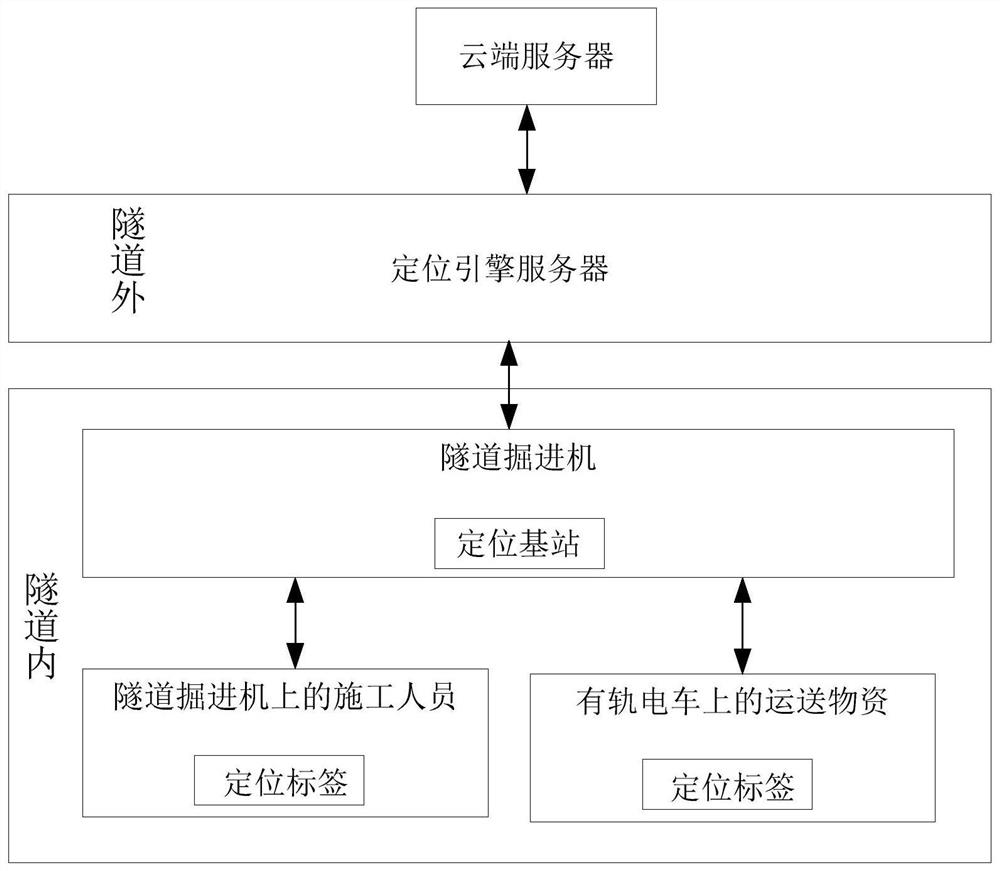

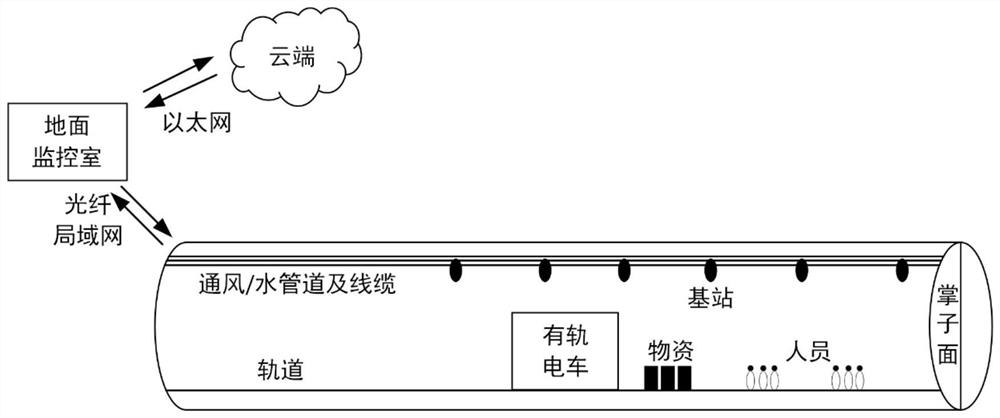

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0020] Explanation of technical terms:

[0021] Tunnel boring machine: It is a new type of advanced tunnel construction machine that uses rotary cutters to excavate, simultaneously breaks the surrounding rock in the hole and excavates, and forms the entire tunnel section, including shield tunnel boring machines.

[0022] Segment ring: When the shield tunnel boring machine digs forward for a certain distance, it is necessary to assemble the tunnel lining at the excavated place, that is, the segment ring. The support of the tunnel is spliced by segments one by one.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com