An anti-rotation orthopedic internal fixator

An internal fixation, anti-rotation technology, applied in the field of medical devices, can solve the problems of damage to the blood supply of the femoral head, large trauma, and damage to the blood supply, and achieve the effects of avoiding ischemic necrosis, avoiding trauma, and avoiding blood supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

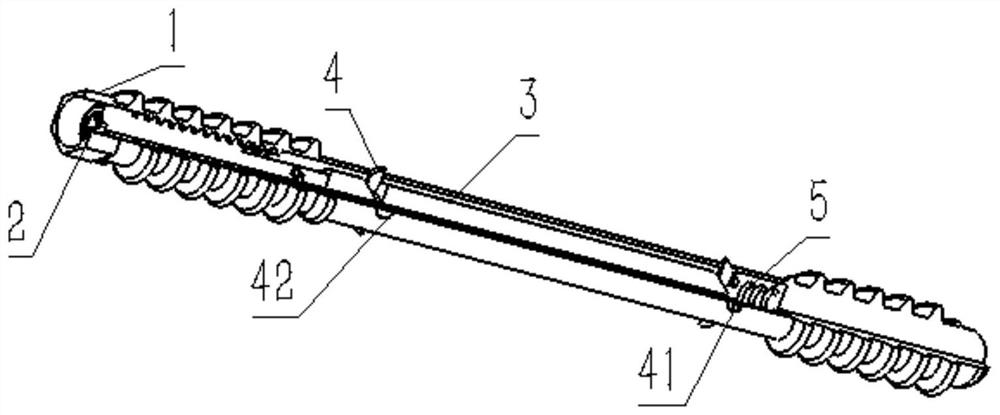

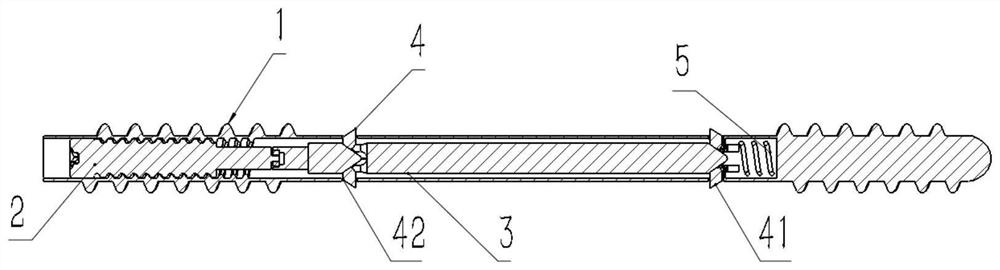

[0050] like Figure 1-2As shown, it is an anti-rotation orthopedic internal fixation device of the present invention, which includes an outer sleeve 1, a positioning assembly 4, an operating assembly for controlling the movement of the positioning assembly 4, and a return spring 5; the operating assembly includes a proximal push rod 223 and The distal sliding rod 3; the proximal push rod 223 is arranged inside the outer sleeve 1 and is slidably connected with the outer sleeve 1; the distal sliding rod 3 is arranged inside the outer sleeve 1 and is located inside the proximal push rod 223 , the distal slide bar 3 is slidably connected with the outer sleeve 1; the positioning components 4 are respectively arranged at both ends of the distal slide bar 3, and are detachably connected with the distal slide bar 3; one end of the return spring 5 is connected to the distal end The end of the slide rod 3 away from the mouth of the threaded pipe 11 is integrally connected, and the other...

Embodiment 2

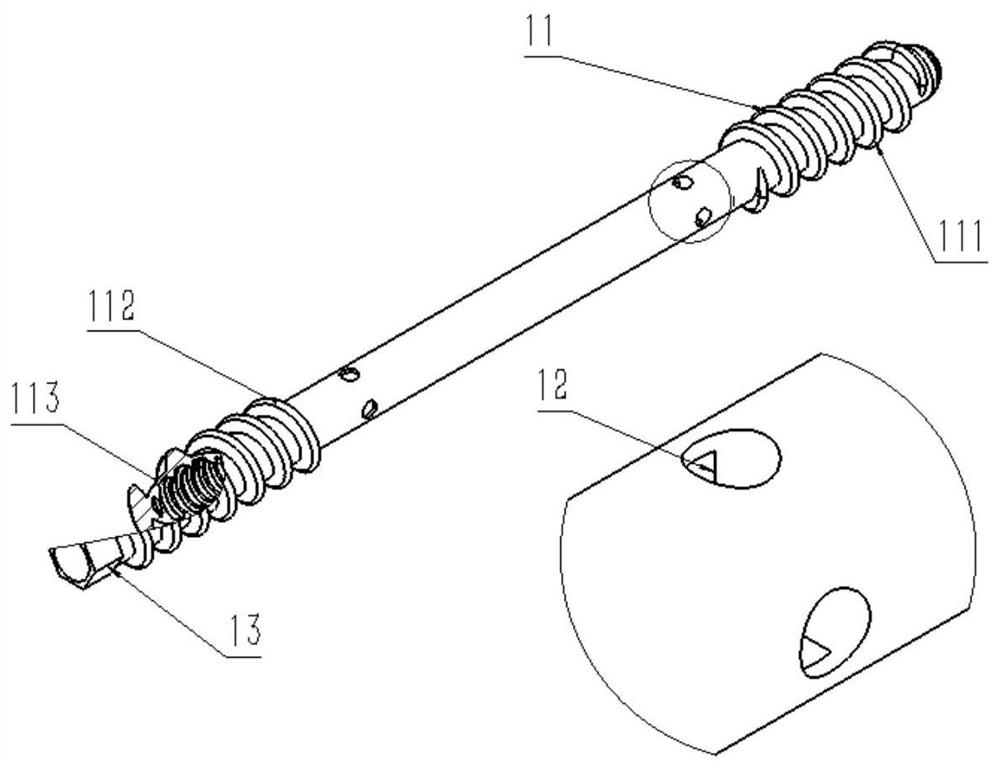

[0056] like Figure 3-9 As shown, the following specific settings are carried out on the basis of embodiment 1 for this embodiment:

[0057] The threaded tube 11 is a tubular structure with round holes on the side walls at both ends. The outer two ends are respectively provided with a distal thread 111 and a proximal thread 112 for fixing the whole body in the patient's body. The inner opening is provided with a proximal push rod. 223 to match the internal thread 113.

[0058] The distal guide structure 12 is an arc-shaped plate structure; the distal guide structure 12 is arranged inside the round hole of the outer tube 1 away from the nozzle end, and is integrally connected with the outer tube 1 .

[0059] The tightening structure is a hexagonal prism structure with a cylindrical through hole in the center, which is arranged at the nozzle of the outer casing 1 and integrally connected with the outer casing 1 .

[0060] The stud 21 is a cylindrical structure with threads on ...

Embodiment 3

[0070] like Figure 10-13 As shown, the difference between this embodiment and embodiment 2 is:

[0071] Both sides of the threaded tube 11 are respectively provided with round holes, and the inner sides of the round holes are respectively provided with inclined surfaces for assisting the entry and exit of the distal positioning structure 41 and the proximal positioning structure 42 .

[0072] The rod body 31 is a rectangular columnar structure; the distal slideway 322 includes a distal I-shaped slideway 3221 ; the proximal slideway 332 includes a proximal I-shaped slideway 3321 .

[0073] The far-end I-shaped slideway 3221 is a T-shaped structure, which is arranged on the central axis of the distal inclined surface 321, and is integrally connected with the distal-end inclined surface 321; the proximal-end I-shaped slideway 3321 is a T-shaped structure, which is arranged on the on the central axis of the proximal bevel 331 and integrally connected with the proximal bevel 331 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com