High-precision electronic waste circuit board high-value element integrated processing equipment

A technology for waste circuit boards and processing equipment, applied in the field of circuit board processing, can solve the problems of low recycling rate, environmental pollution, low economic benefits, etc., and achieve the effect of easy full contact, easy scanning and collection, and ensuring cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

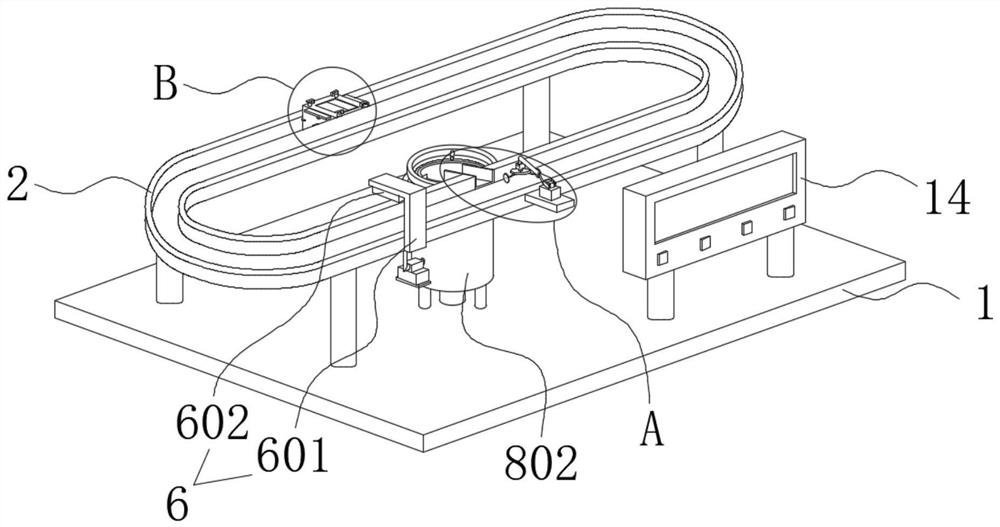

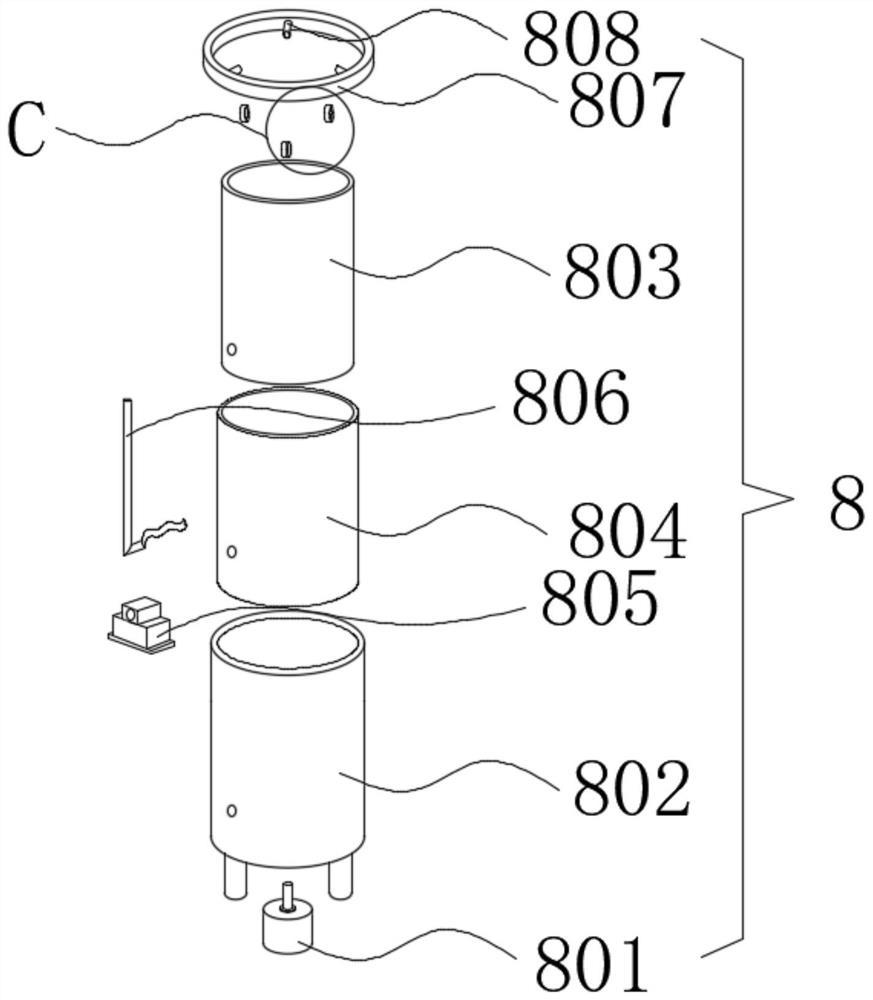

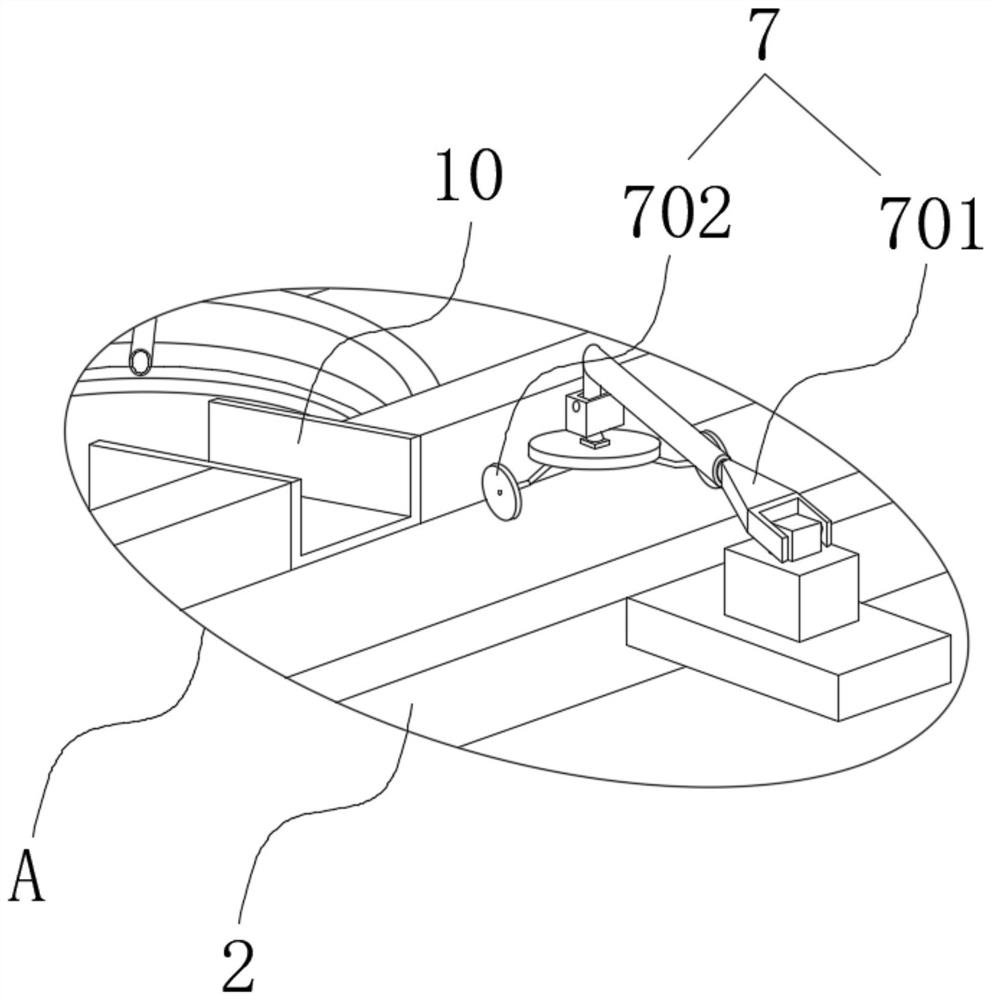

[0043] see Figure 1-7 , in the present invention, a high-precision integrated processing equipment for high-value components of electronic waste circuit boards includes a bottom plate 1, a track 2 is fixedly connected to the top of the bottom plate 1, and a driving trolley 3 is arranged inside the track 2, and the inside of the driving trolley 3 A discharge assembly 4 is provided, a clamping assembly 5 is provided on the top of the drive trolley 3, a photoelectric assembly 6 is provided outside the track 2, a cutting assembly 7 is provided outside the track 2, and a separation assembly 8 is provided on the top of the bottom plate 1.

[0044] In the present invention, the setting of the bottom plate 1 is used to support the whole device. When it is necessary to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap