Automatic material feeding device for numerical control automatic plate processing

A technology for automatic feeding and sheet metal processing, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing service life, increasing the workload of staff, reducing sheet conveying efficiency, etc., to extend service life, Avoid repeated start and stop, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

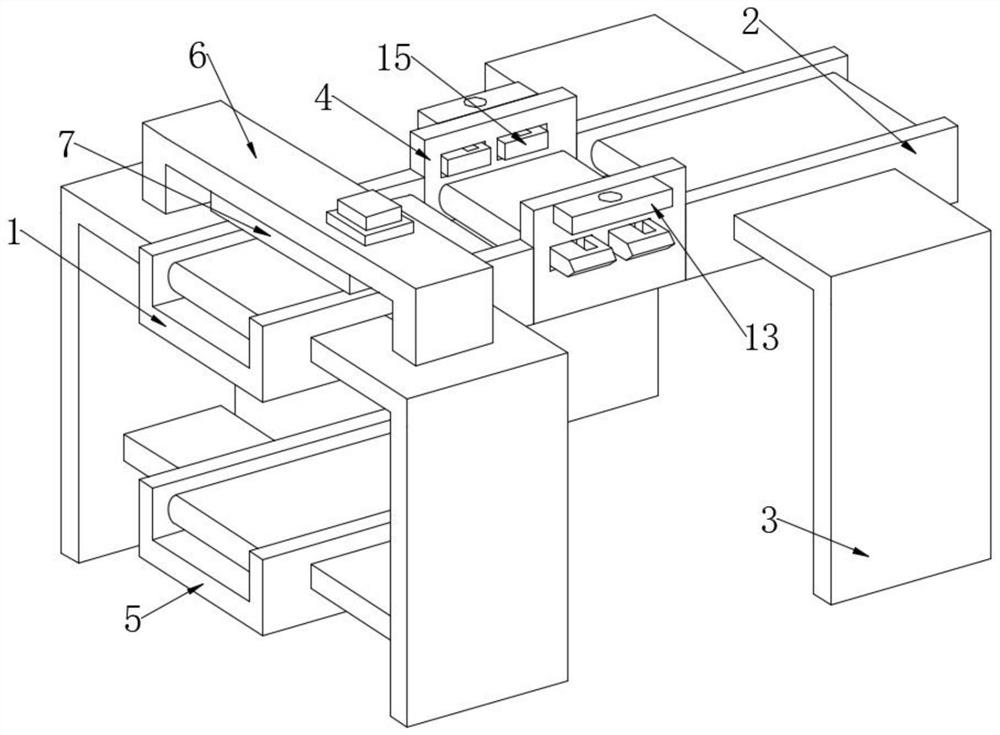

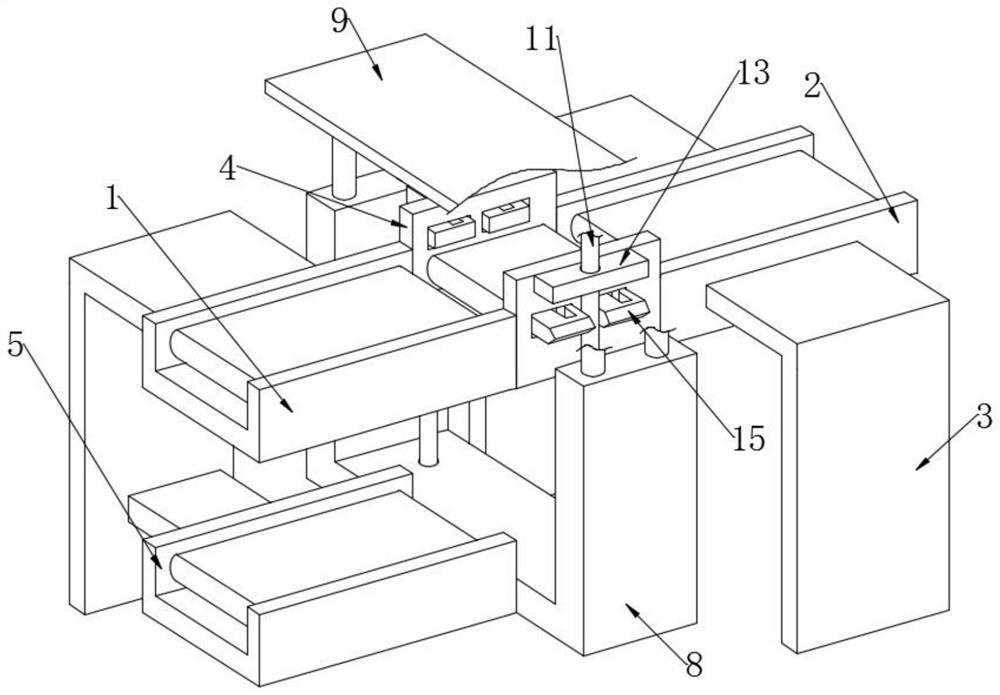

[0024] refer to Figure 1-3 , an automatic feeding device for CNC automatic plate processing, comprising a first conveyor frame 1 and a second conveyor frame 2, L-shaped support frames 3 are installed on the front and back sides of the first conveyor frame 1 and the second conveyor frame 2, the first The opposite surfaces of the transport frame 1 and the second transport frame 2 are overlapped with a movable transport frame 4 .

[0025] Between the two L-shaped support frames 3 of the first transport frame 1, a return transport frame 5 is fixedly connected by a support plate, and the inner walls of the first transport frame 1, the second transport frame 2, the movable transport frame 4 and the return transport frame 5 are uniform. Set with conveyor belt.

[0026] The upper surface of the two L-shaped support frames 3 is equipped with a X-shaped board 6, and the lower surface of the X-shaped board 6 is equipped with a laser sensor 7. The model of the laser sensor 7 is ZLDS100,...

Embodiment 2

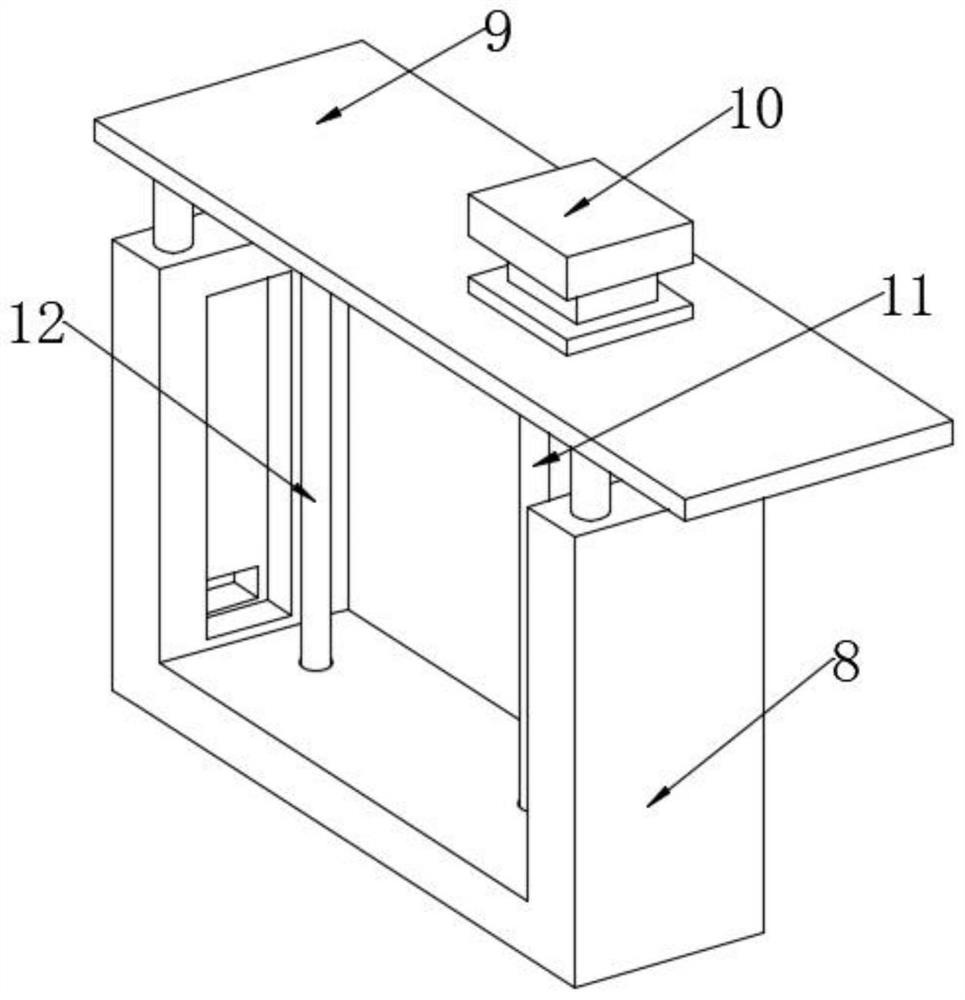

[0031] refer to Figure 4-5 Different from Embodiment 1, the front and back sides of the movable carrier 4 are provided with two square grooves, the inner top wall of the square groove is equipped with a square push rod 14, and the inner wall of the square groove is slidably connected with a tapered top plate 15.

[0032] One side of the conical top plate 15 is provided with two slopes, the upper surface of the conical top plate 15 is provided with a draw-in groove, the inner wall of the draw-in groove is slidingly connected with the surface of the square push rod 14, the inner wall of the draw-in groove is fixedly connected with a spring 16, and One end of the spring 16 away from the inner wall of the slot is fixedly connected with the square push rod 14 .

[0033] The front and rear inner walls of the support platform 8 are provided with sliding grooves and grooves respectively, and the inner walls of the sliding grooves and the grooves are all compatible with the conical to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com