Wood board cutting and scribing device for furniture production

The technology of a wooden board and a scribing device, which is applied in the field of furniture, can solve the problems of deviation of the wooden board, complicated operation steps, affecting the scribing accuracy, etc., and achieves the effects of enhancing the tensioning force, enhancing the fixing effect, and improving the scribing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

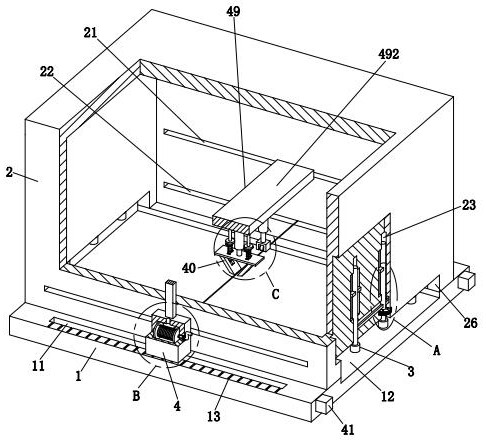

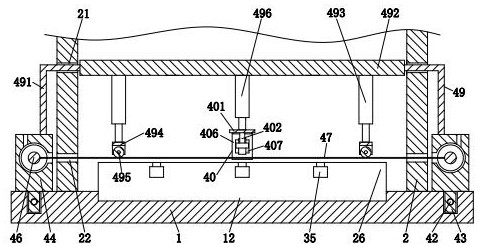

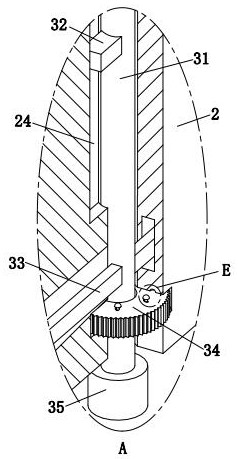

[0029] see figure 1 and figure 2 , a furniture production wood board cutting and scribing device, including a base 1, a closed box 2, a fixing unit 3 and a scribing unit 4, the upper end of the base 1 is symmetrically provided with a limit chute 11 front and rear, and the center of the upper end of the base 1 is provided with In the discharge chute 12, the upper end of the limit chute 11 is provided with scales 13 at equal intervals on the side away from the closed box 2; the scales 13 can easily adjust the position of the scribing unit 4, and can ensure the accuracy during adjustment, and then To ensure the accuracy of scribing; the closed box 2 is fixedly installed on the upper end of the base 1 , the fixing unit 3 is installed inside the closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com