Automatic carton opening auxiliary device for reducing staff intensity and improving production

A technology for auxiliary equipment and boxes, applied in the field of cartons, can solve the problems of limited automation and cannot completely replace labor, and achieve the effect of reducing the strength of employees and facilitating unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

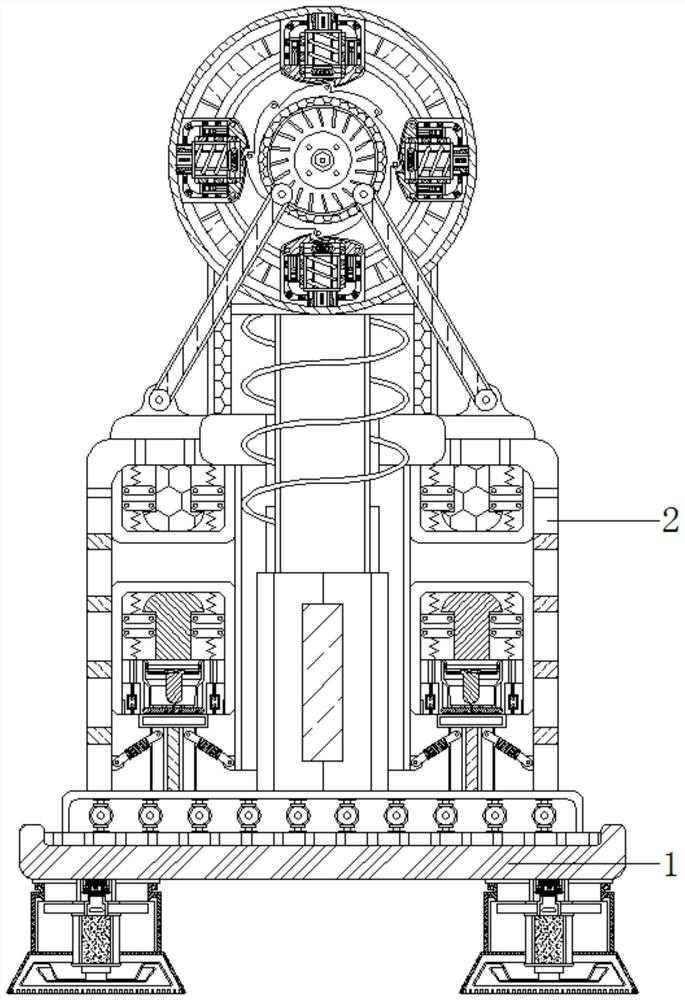

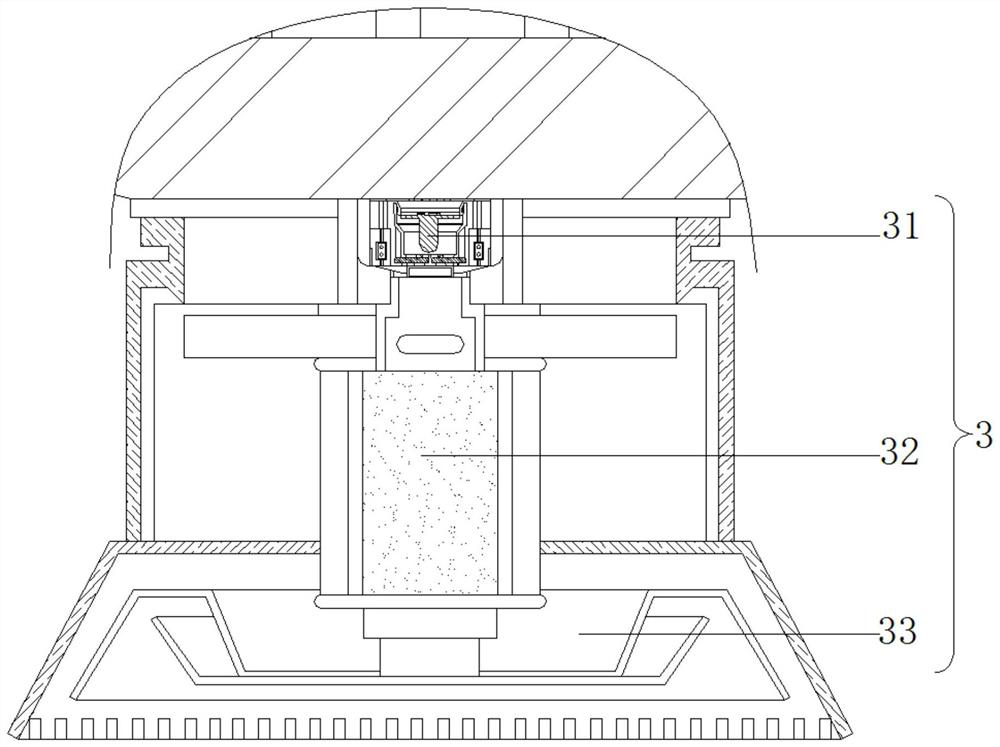

[0026] see Figure 1-4 , an auxiliary equipment for automatic carton unpacking to reduce the strength of employees and improve production, including a rotating mechanism 6 and an adsorption mechanism 5. The rotating mechanism 6 includes a push-pull rod 61, and the top of the push-pull rod 61 is movably connected with a rotating wheel 62, and the rotating wheel 62 is externally movable Connected with a clamping plate 63, the clamping plate 63 is movably connected to the limiting teeth 64, and the side of the limiting teeth 64 away from the clamping plate 63 is movably connected to a closing spring 65, and the closing spring 65 is movably connected to a connecting seat 66 externally.

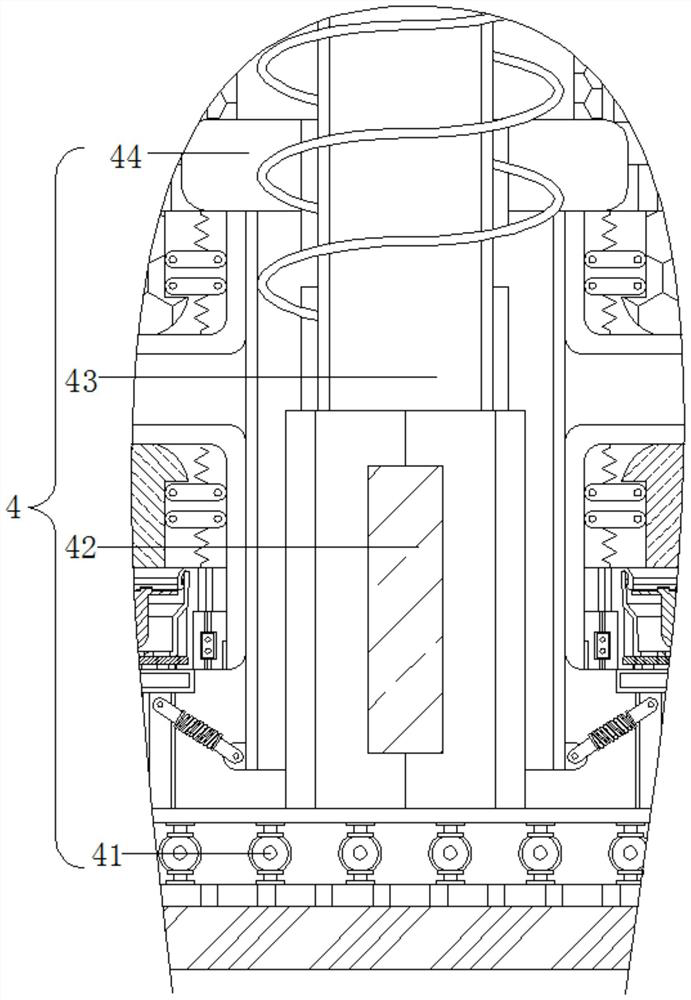

[0027] Further, the transmission mechanism 4 is movably connected to the bottom of the rotating mechanism 6, the left and right sides of the transmission mechanism 4 are movably connected to the adsorption mechanism 5, the outer part of the transmission mechanism 4 is movably connected to the prote...

Embodiment 2

[0033] see figure 1 , image 3 and Figure 5 , an auxiliary equipment for automatic carton unpacking to reduce the strength of employees and improve production, including a rotating mechanism 6 and an adsorption mechanism 5. The rotating mechanism 6 includes a push-pull rod 61, and the top of the push-pull rod 61 is movably connected with a rotating wheel 62, and the rotating wheel 62 is externally movable Connected with a clamping plate 63, the clamping plate 63 is movably connected to the limiting teeth 64, and the side of the limiting teeth 64 away from the clamping plate 63 is movably connected to a closing spring 65, and the closing spring 65 is movably connected to a connecting seat 66 externally.

[0034] Further, the adsorption mechanism 5 includes a connecting rod 51, a buffer spring 52 is movably connected to the outside of the connecting rod 51, an electrical block 53 is movably connected to the top of the connecting rod 51, and an adsorption contact 54 is movably ...

Embodiment 3

[0039] see Figure 1-5, an auxiliary equipment for automatic carton unpacking to reduce the strength of employees and improve production, including a rotating mechanism 6 and an adsorption mechanism 5. The rotating mechanism 6 includes a push-pull rod 61, and the top of the push-pull rod 61 is movably connected with a rotating wheel 62, and the rotating wheel 62 is externally movable Connected with a clamping plate 63, the clamping plate 63 is movably connected to the limiting teeth 64, and the side of the limiting teeth 64 away from the clamping plate 63 is movably connected to a closing spring 65, and the closing spring 65 is movably connected to a connecting seat 66 externally.

[0040] Further, the adsorption mechanism 5 includes a connecting rod 51, a buffer spring 52 is movably connected to the outside of the connecting rod 51, an electrical block 53 is movably connected to the top of the connecting rod 51, and an adsorption contact 54 is movably connected to the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com