Elevator guide rail support preassembling equipment

A technology for elevator guide rails and equipment, applied in the field of pre-installed equipment for elevator guide rail brackets, which can solve problems such as inconvenient up and down movement, low adaptability, and influence of elevator guide rail installation, and achieve the effect of ensuring installation accuracy and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

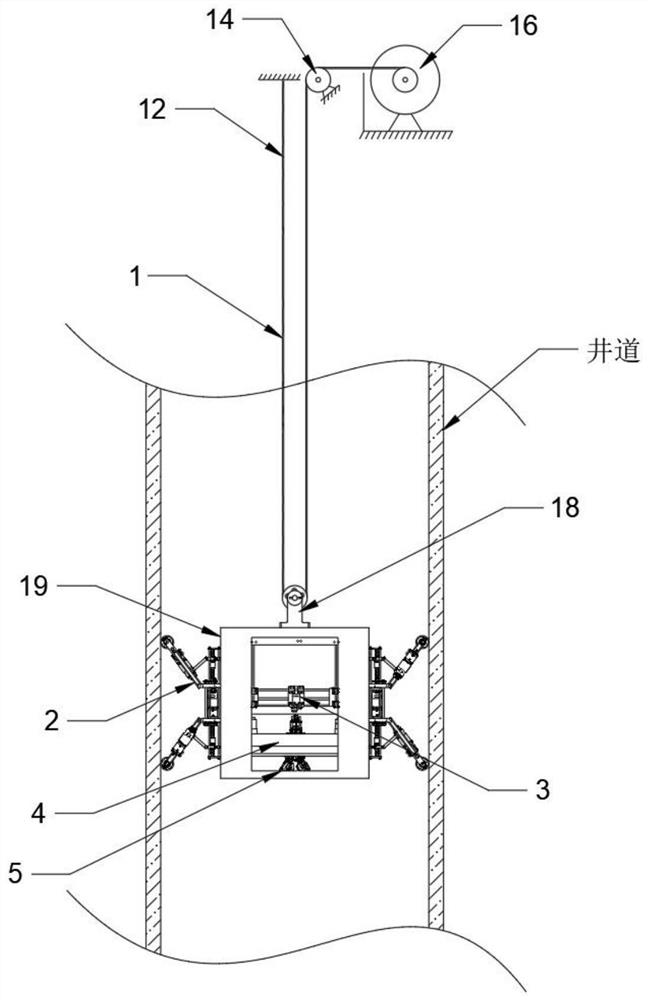

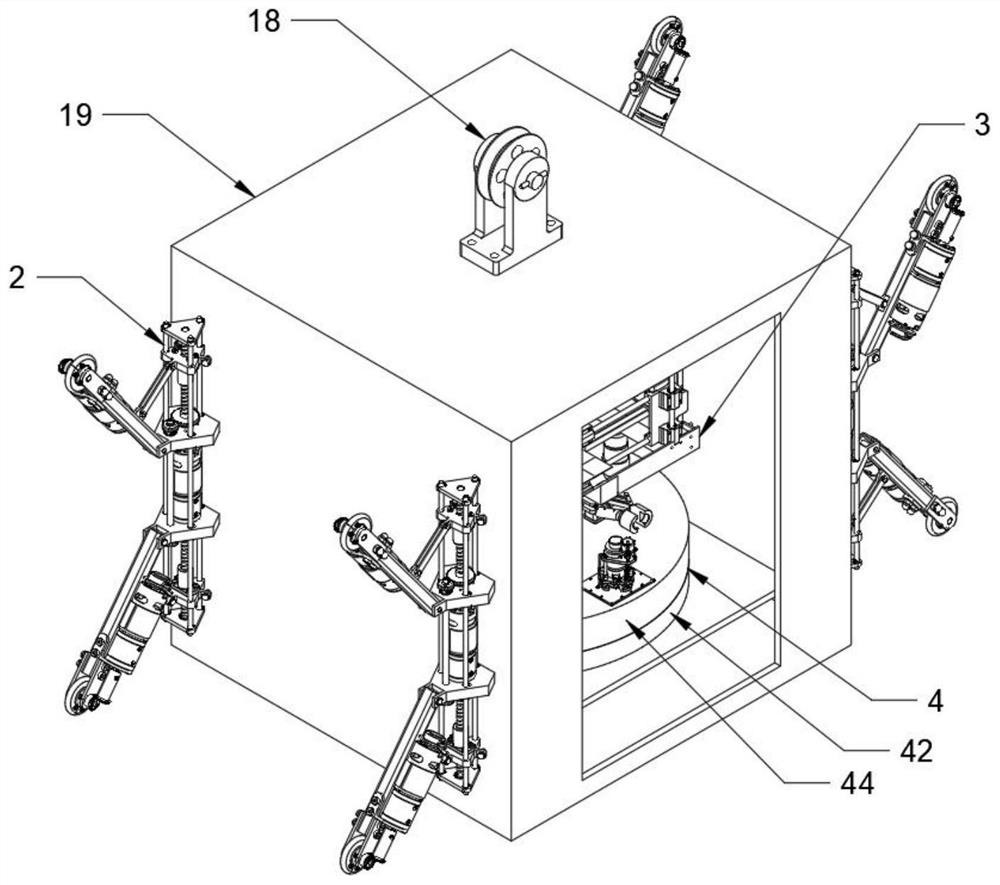

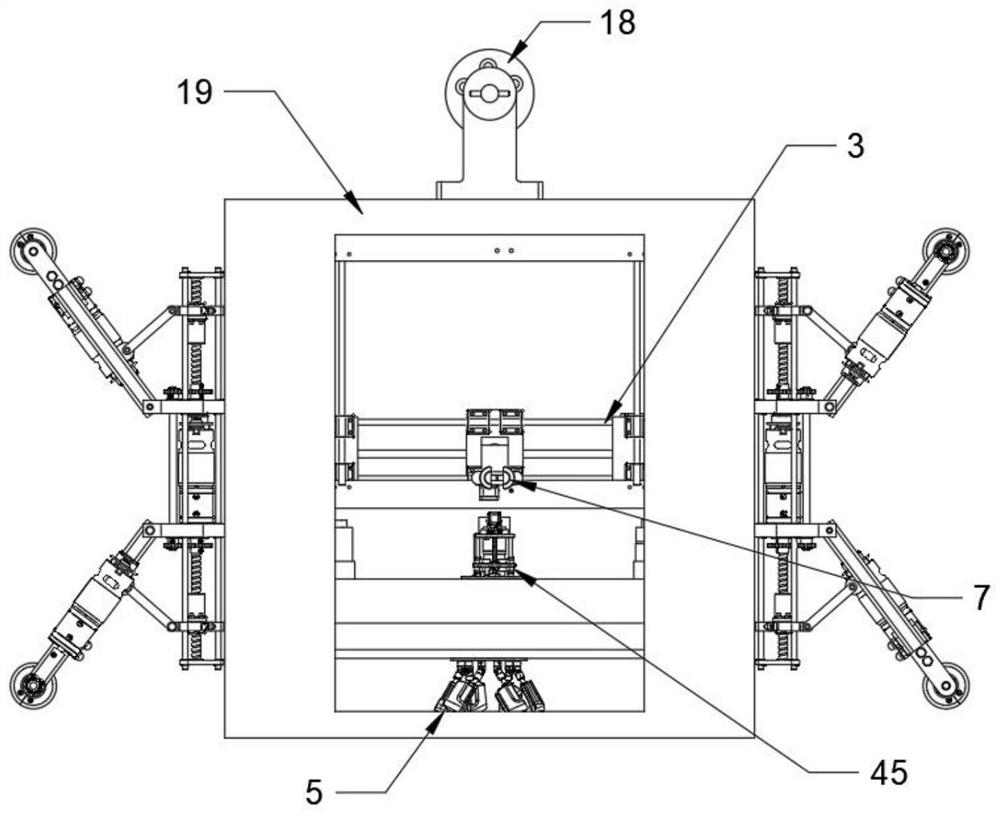

[0066] Such as Figure 1-12 as shown,

[0067] An elevator guide rail support pre-installation equipment, comprising:

[0068] traction mechanism 1;

[0069] The outer box 19 is connected with the traction mechanism 1, and can move up and down in the hoistway under the action of the traction mechanism 1;

[0070] The tool switching mechanism 4, which is installed in the outer box 19, includes a tool switching power motor 42, a tool loading tray 44 that is connected to the tool switching power motor 42, and a plane grinder 46 and a drilling rig that are arranged on the tool loading tray 44 45;

[0071] Vertical and horizontal displacement mechanism 3, vertical and horizontal displacement mechanism 3 is installed in the outer box body 19;

[0072] The telescopic mechanism 6 is installed on the vertical and horizontal displacement mechanism 3, and the telescopic mechanism 6 can move in a plane parallel to the installation plane under the action of the vertical and horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com