Soft intelligent borescope device and method applied to aero-engine

An aero-engine and software technology, applied in the field of aviation science and industry, can solve problems such as low air pressure, inability to achieve real-time monitoring, and difficulty in driving other components or equipment, etc., to achieve strong working ability, simple and convenient working principle, and wide application face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

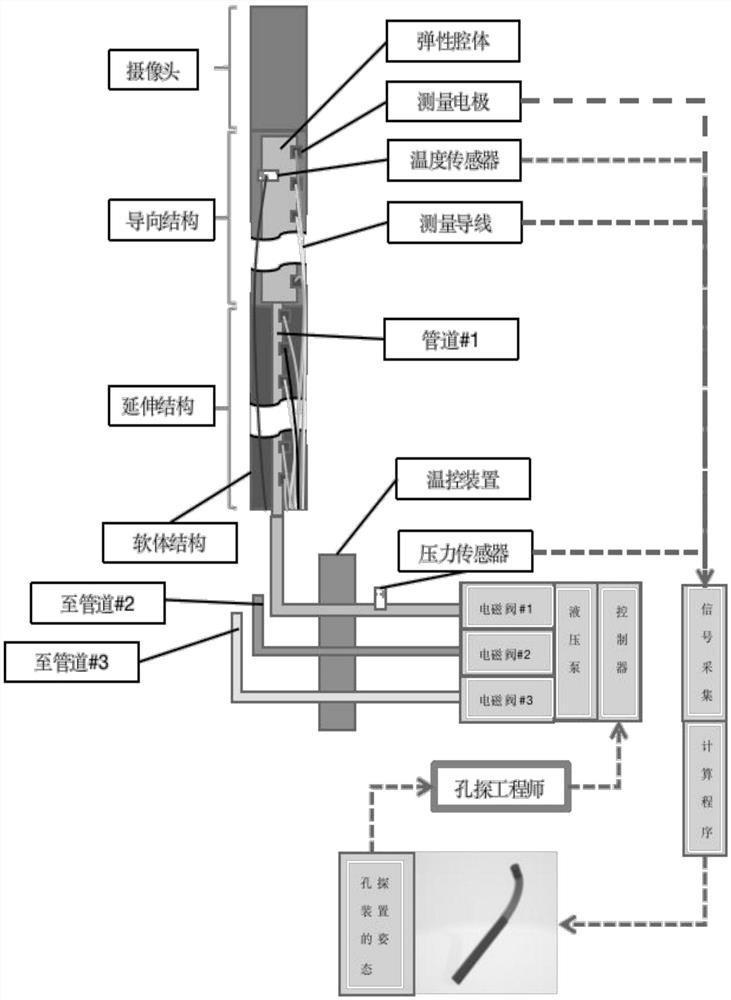

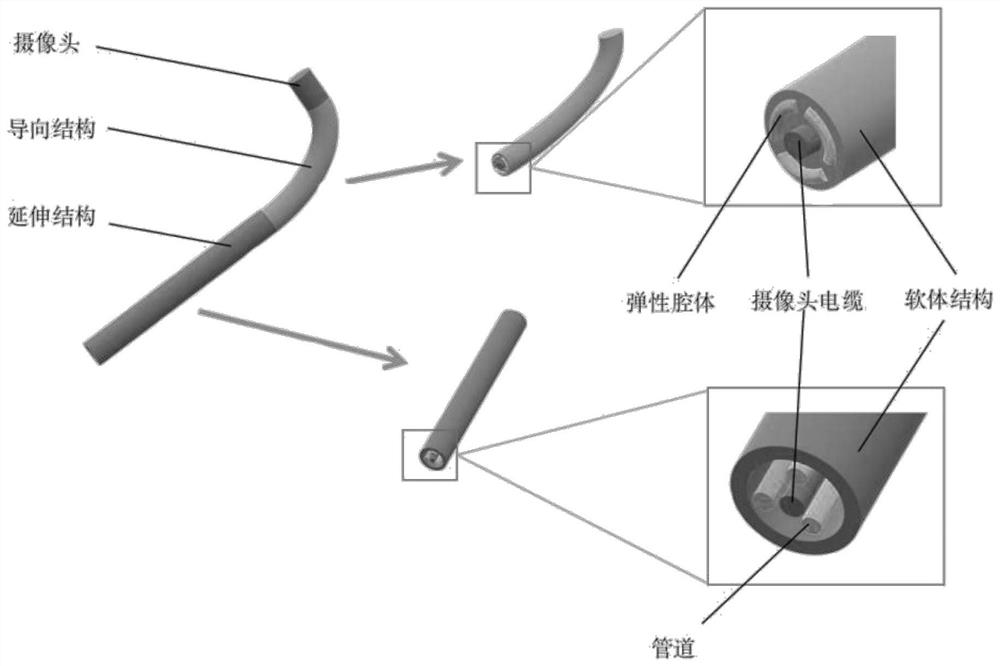

[0037] Embodiment 1: A kind of software intelligent bore detection device and method applied to aero-engine, such as figure 1 The data shown are based on the pressure sensor, temperature sensor and temperature controller data, as the input data of the control system, timely adjust the hydraulic pump supply pressure to drive the guiding structure to move in all directions, and dynamically adjust the camera's pose;

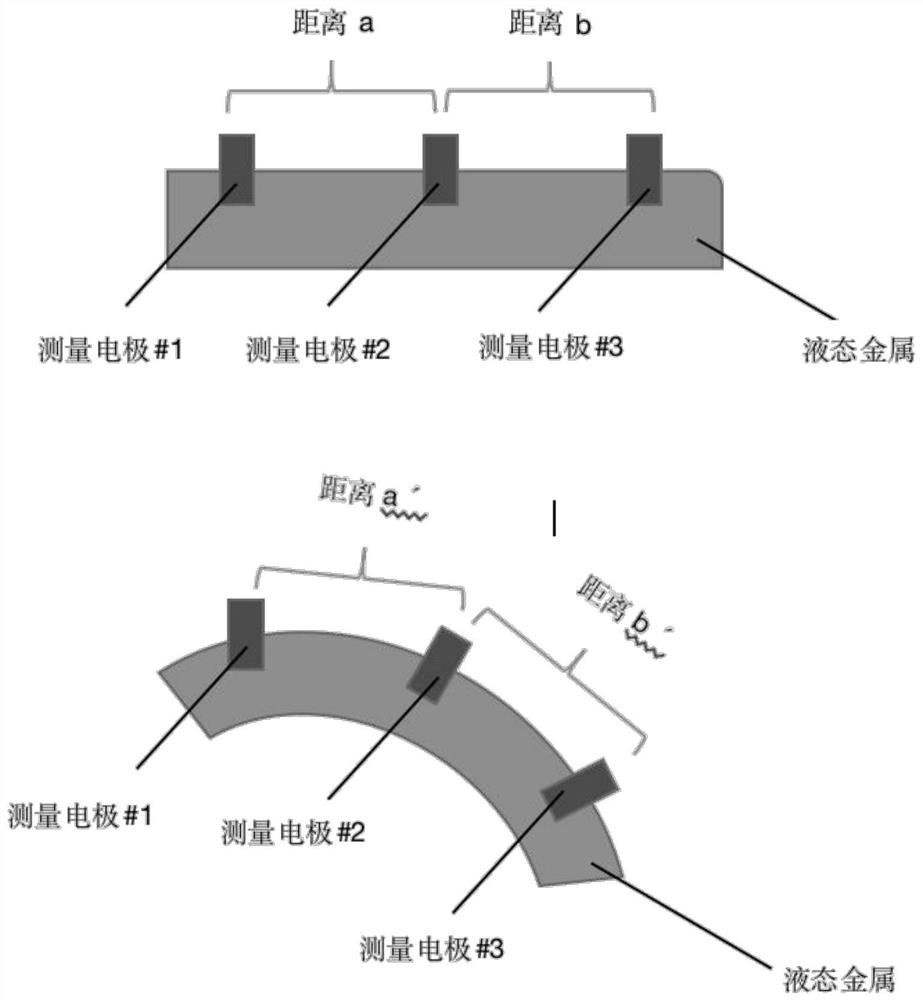

[0038] Among them, the liquid metal is used as the hydraulic medium to drive the deformation of the guiding structure for guidance, and at the same time, the resistance value of the liquid metal between any two measuring electrodes is used, combined with the different deformations of the soft structure layer, resulting in changes in the distance between the measuring electrodes. The distribution of metals also changes.

[0039] In this embodiment, there is liquid metal between any two measuring electrodes, so by measuring the resistance value between any two measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com