Process trend analysis and prediction method based on intelligent instrument

A smart instrument and trend analysis technology, applied to instruments, character and pattern recognition, computer components, etc., can solve the problems of short prediction period, slow training speed, and difficulty in ensuring real-time performance, and achieve prediction and early warning with a small amount of calculation , to avoid the effect of delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

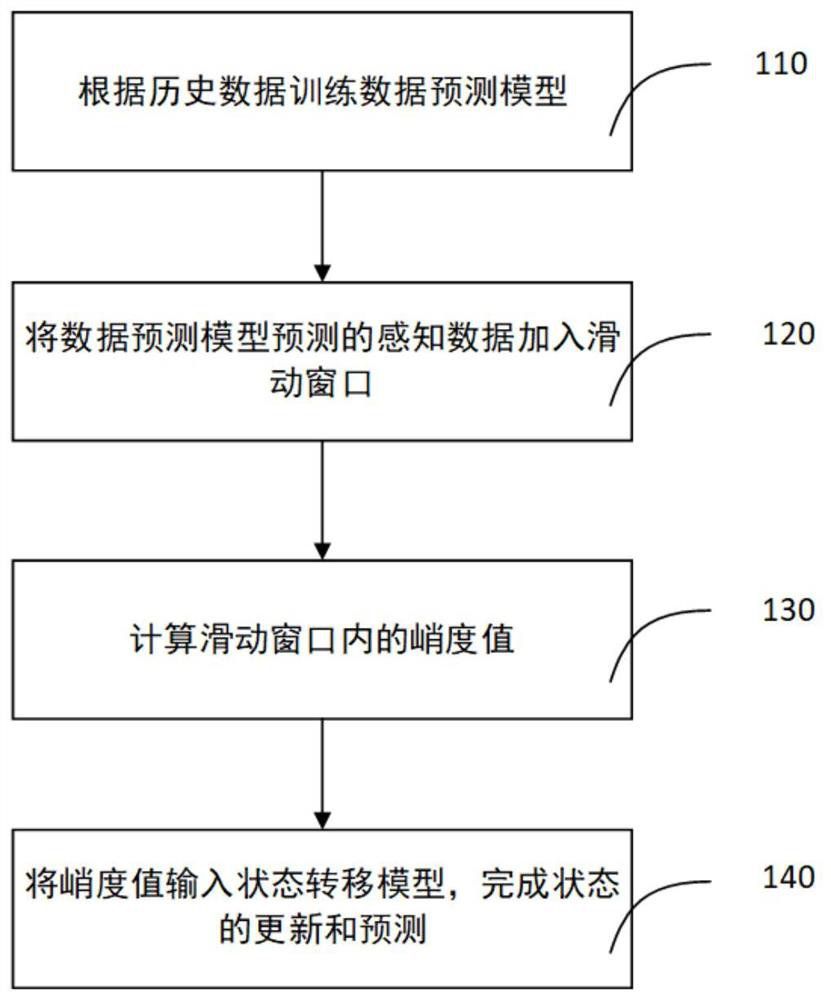

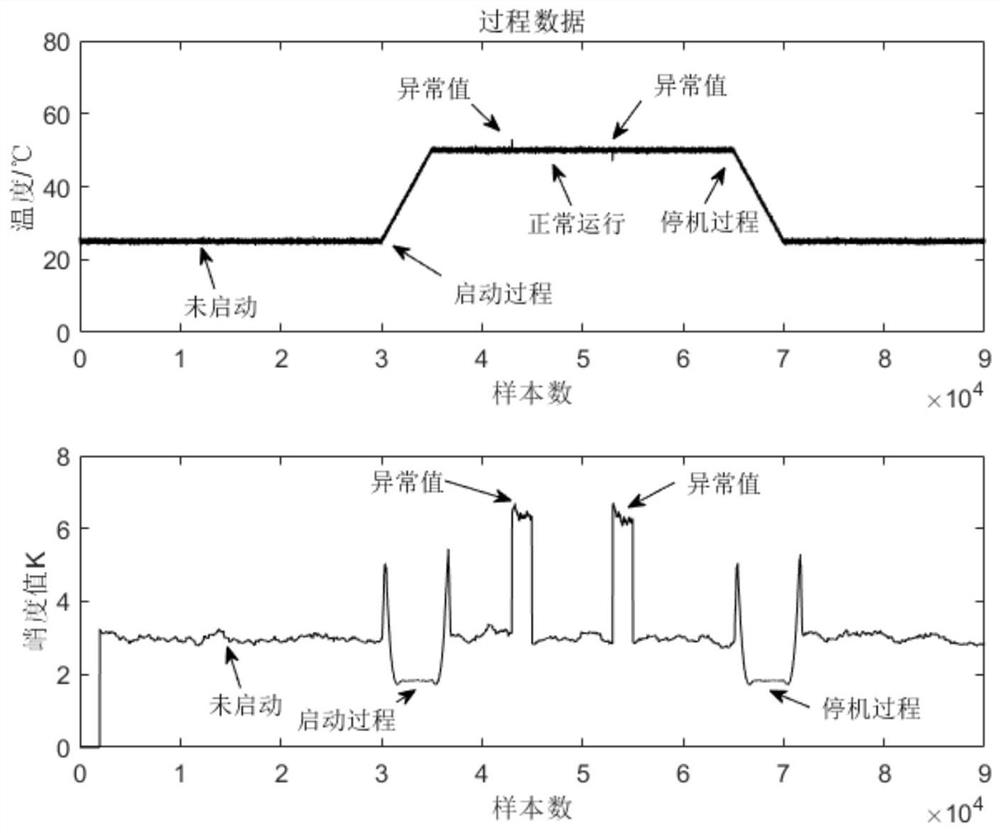

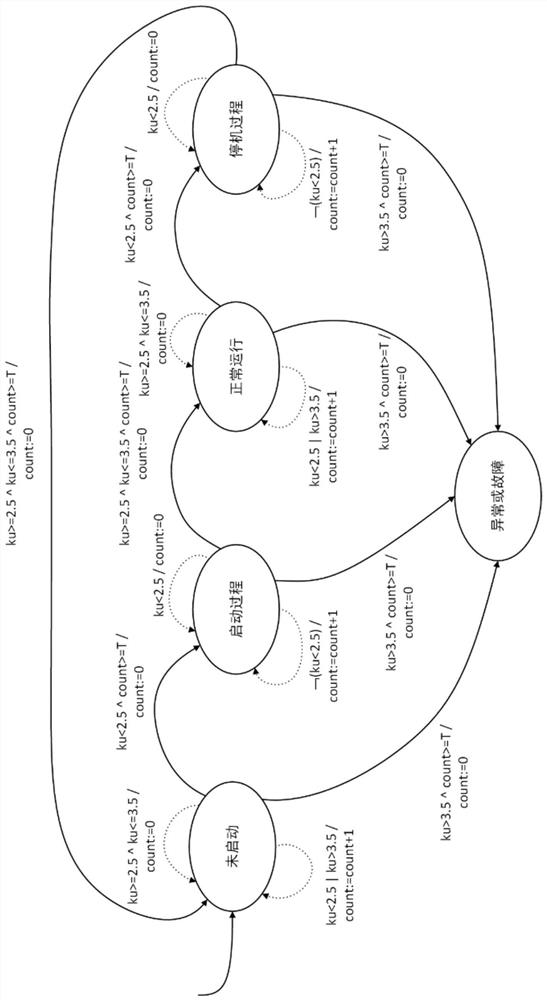

[0025] figure 1 It is a block diagram of steps of the method for analyzing and predicting process trends based on smart instruments in the present invention, please refer to figure 1 , a method for analyzing and predicting process trends based on smart meters, including: smart meters record historical sensing data; train data prediction models (step 110) according to historical sensing data; add the sensing data predicted by the data prediction model to the sliding window (step 120); calculate the kurtosis value in the sliding window (step 130); input the kurtosis value into the state transition model, and complete the update and prediction of the state (step 140). The kurtosis value in the present invention is a numerical statistic that reflects the distribution characteristics of the vibration signal, and is a normalized fourth-order central moment, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com