Production, inspection and identification integrated equipment for fireproof flame-retardant cable

A production inspection, fire-proof and flame-retardant technology, applied in the direction of cable/conductor manufacturing, marking conductor/cable, circuit, etc., can solve problems such as leakage and electric shock accidents, insulation reduction, and insufficient cable detection area, so as to avoid missed detection , the effect of increasing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

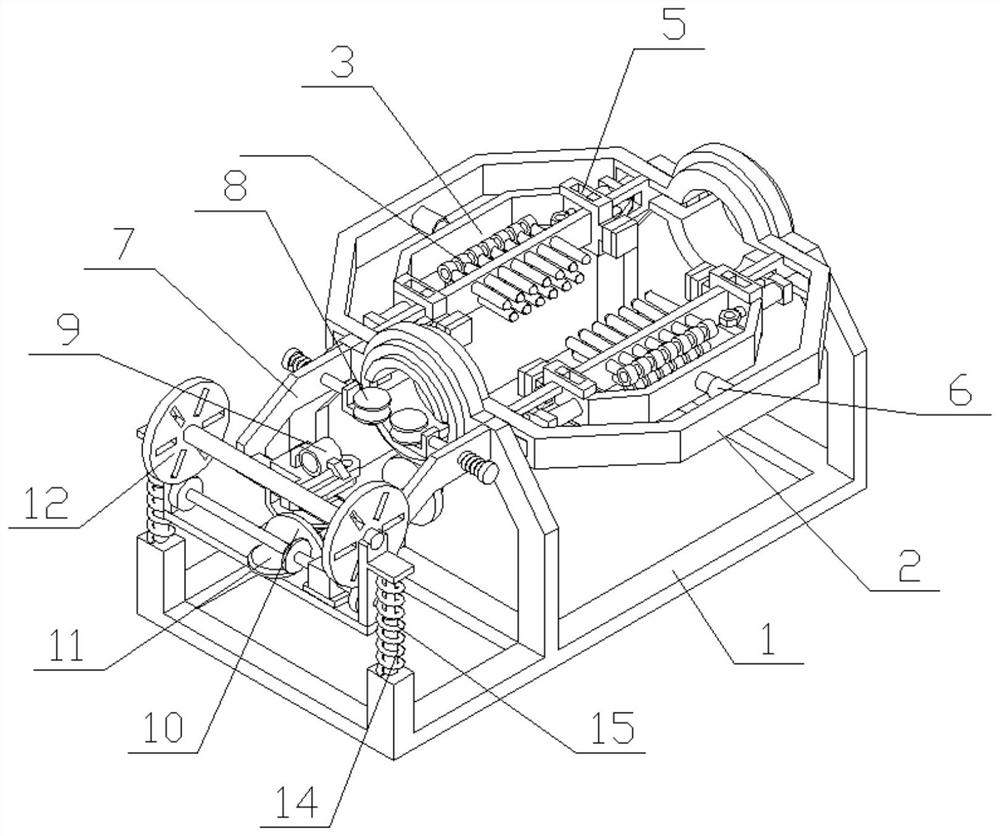

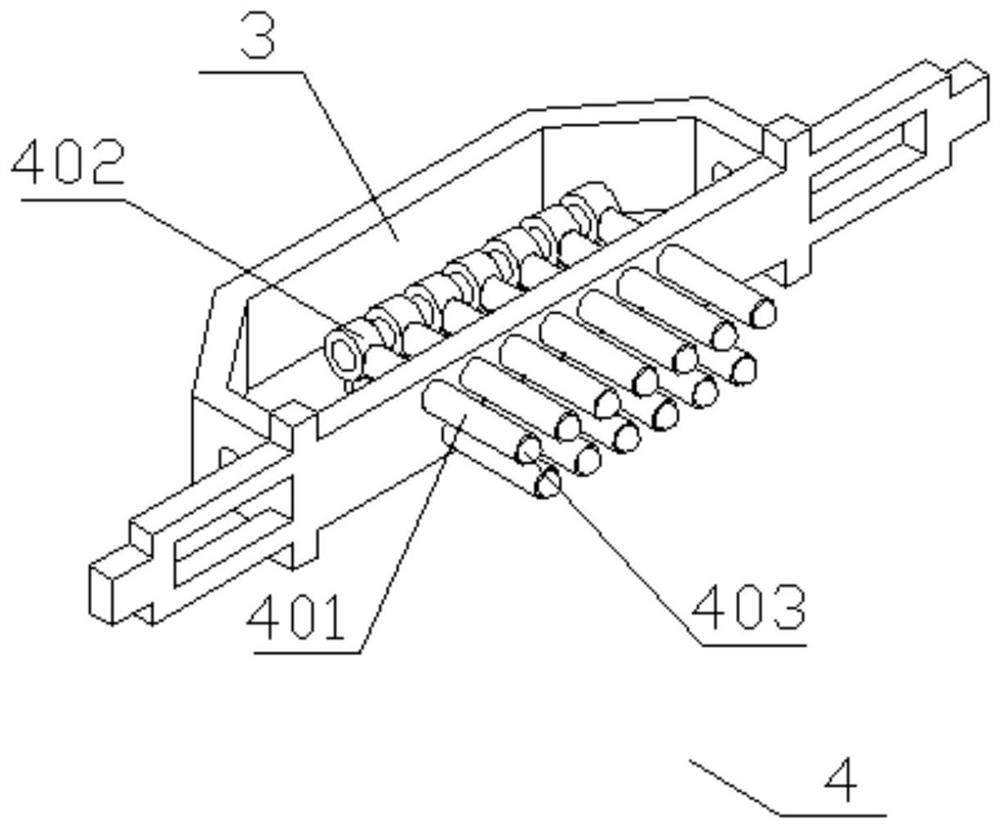

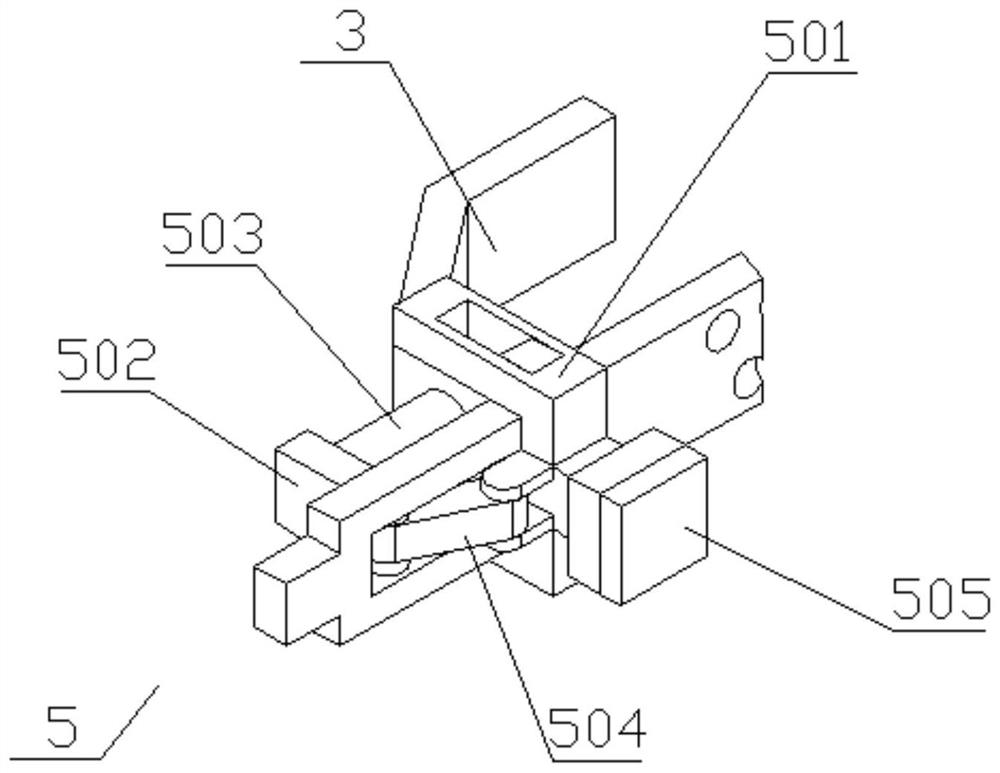

[0030] Combine below Figure 1-8 Describe the specific implementation of the present invention, a kind of integrated equipment for production inspection and identification of fire-proof and flame-retardant cables, including a support mechanism 1, a turret 2 rotatably connected to the support mechanism 1, and a turret 2 fixedly connected to the support mechanism 1 A fixed frame 7, one side of the turret 2 is fixedly connected with an external gear ring 13, and both sides of the turret 2 are slidably connected with a first sliding frame 3, and each of the first sliding frames 3 is connected to the The internal testing of the turret 2 is connected by a hydraulic cylinder 6, and the middle part of each first sliding frame 3 is provided with several detection probes 4, and both sides of each of the first sliding frame 3 are provided with Marking mechanism 5, the marking mechanisms 5 on both sides of each of the first sliding frame 3 are connected by connecting ropes, and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com