Filtering, washing and press-drying container and using method thereof

A technology of container and filter area, which is applied in the field of filter washing and drying container, which can solve the problems of large use cost and operation cost, failure to meet the use requirements, small filter area, etc., to increase the processing capacity, not easy to block, and large filter area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

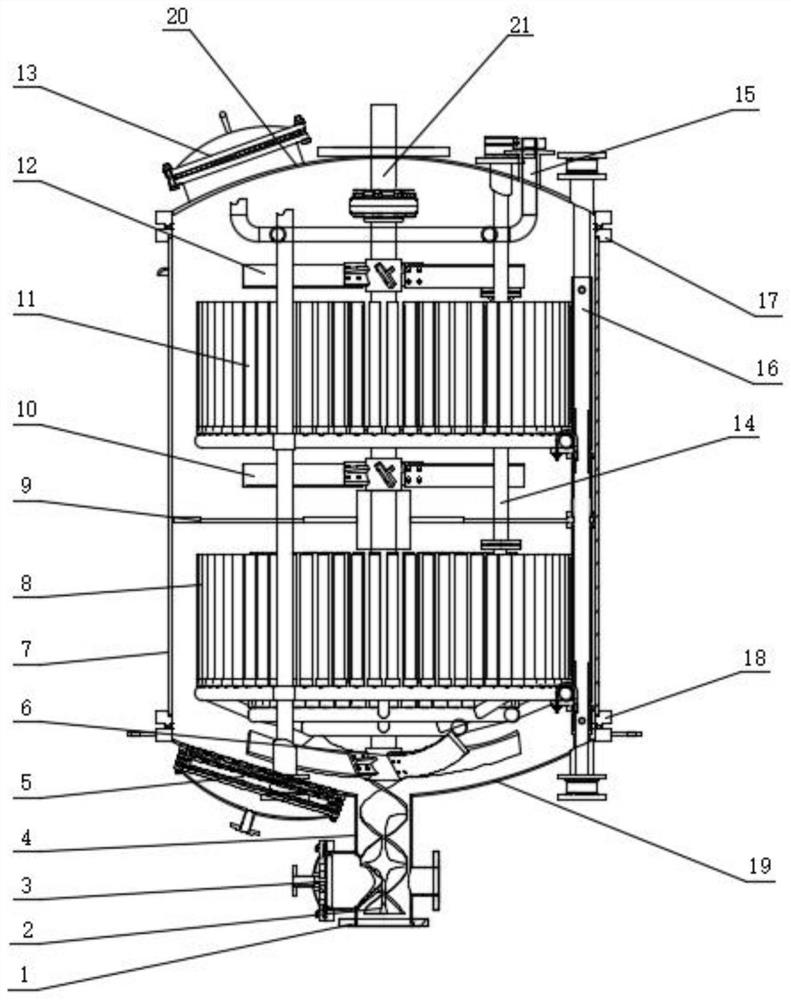

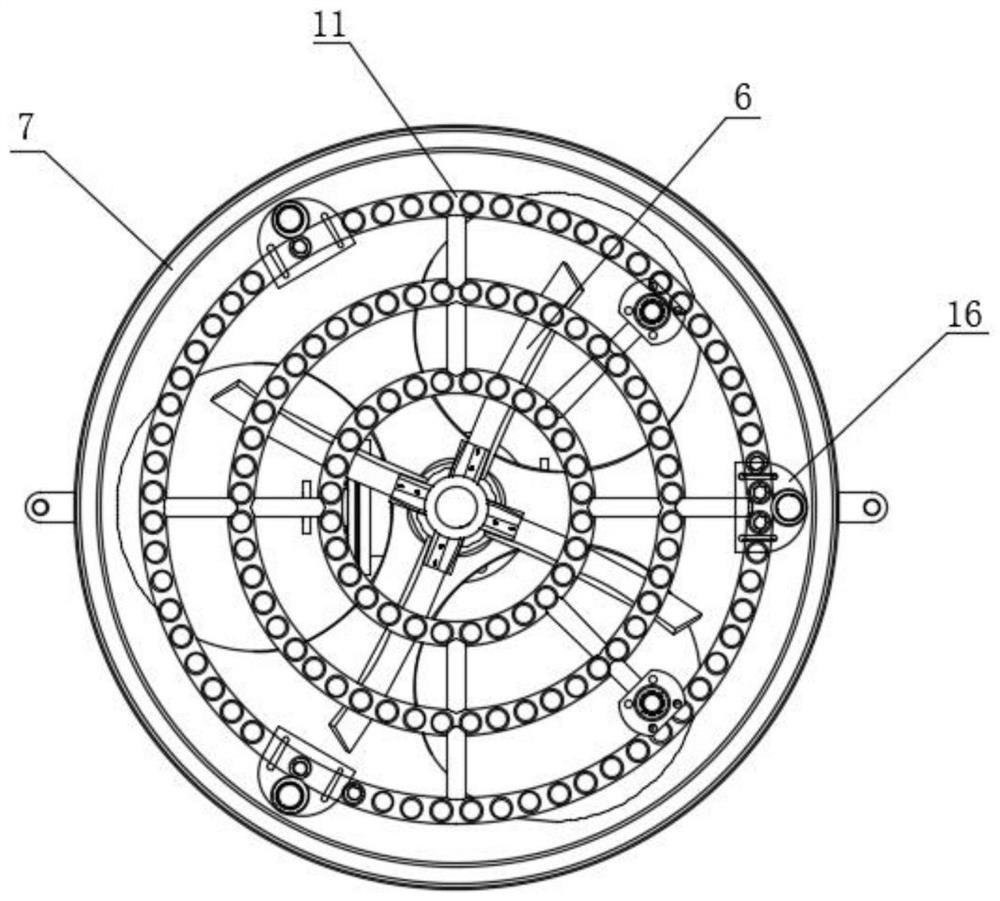

[0020] Embodiment: a kind of filter washing and drying container, as attached Figure 1-2 As shown, the container main body 7 is included, the top of the container main body 7 is provided with a top cover 20, the middle part in the container main body 7 is provided with a rotating shaft 21, and the upper stirring paddle 12 and the middle stirring paddle are arranged successively on the rotating shaft 21 from top to bottom. 10 and the bottom stirring blade 6, the bottom stirring blade 6 is provided with a scraper. The inner wall of the container main body 7 is provided with a row pipe fixing frame 16, and the row pipe fixing frame 16 is provided with an upper filter area 11 and a middle filter area 8, and the upper filter area 11 and the middle filter area 8 are all provided with a ring-shaped row tube. An upside-down filter pipe is installed on the annular pipe row, the upper filter area 11 is arranged between the upper stirring paddle 12 and the middle stirring paddle 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com