Tail gas desulfurization and dust removal ultra-clean integrated device for brick tile kiln

A technology for desulfurization and dust removal, brick and tile kilns, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that exhaust pollutants cannot be effectively removed, pollutants cannot be effectively solved, and ultra-low emissions cannot be achieved. and other problems to achieve the effect of enhancing the contact reaction effect, reducing the potential safety hazard and having a strong purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

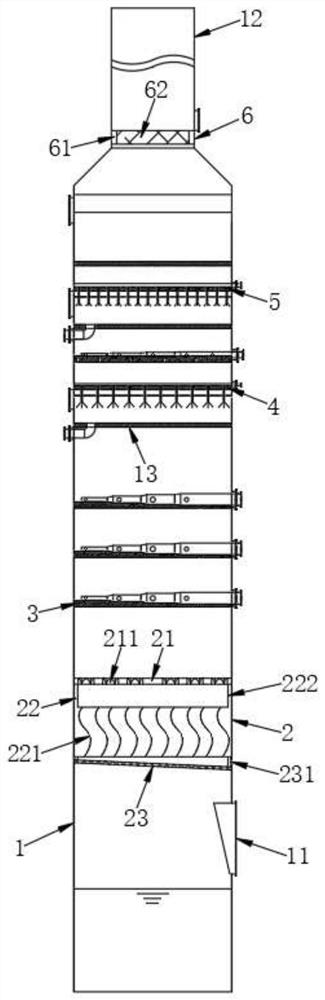

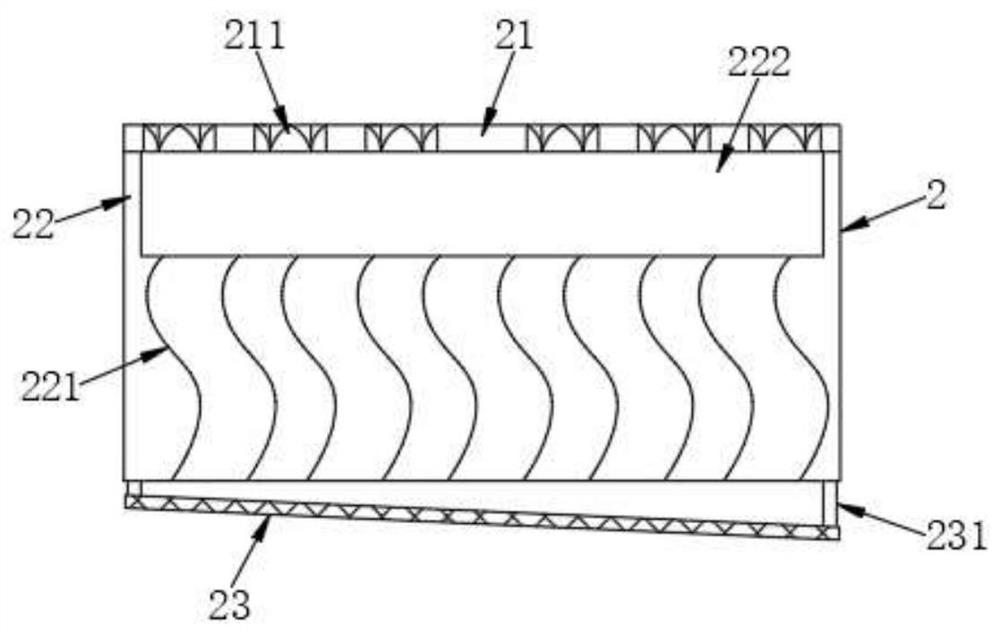

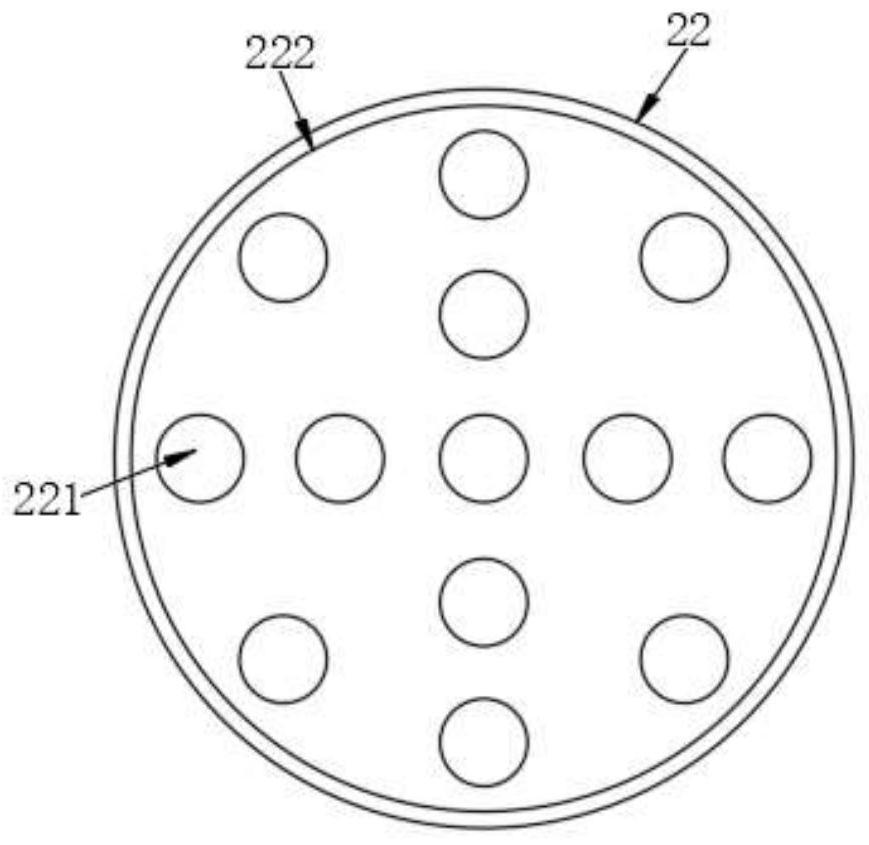

[0022] see Figure 1-Figure 4 , the present invention provides the following technical solutions: including a tower body 1 standing on the ground and used for operation, the bottom of the outer wall of the tower body 1 is provided with an air inlet pipe 11 for releasing exhaust gas inside the tower body 1, and the inside of the tower body 1 is fixed with a utility In the diversion component 2 that diverts the tail gas to rise evenly, the inside of the tower body 1 is fixed with a slurry spray component 3 located above the diversion component 2 and used for spraying slurry, and the inside of the tower body 1 is fixed above the slurry spray component 3 and used for The gas-liquid separation component 4 for gas-liquid separation. The tower body 1 is fixed with a primary defogging component 5 located above the gas-liquid separation component 4 and used to remove the separated mist liquid. The top of the tower body 1 is fixed with a discharge purification The outlet pipe 12 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com