Asymmetric DPF die and manufacturing method thereof

A DPF, asymmetric technology, applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problem of inability to use, similar to manufacture molds, etc., to achieve the effect of low processing cost, convenient processing, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present application will be further described below in conjunction with specific embodiments.

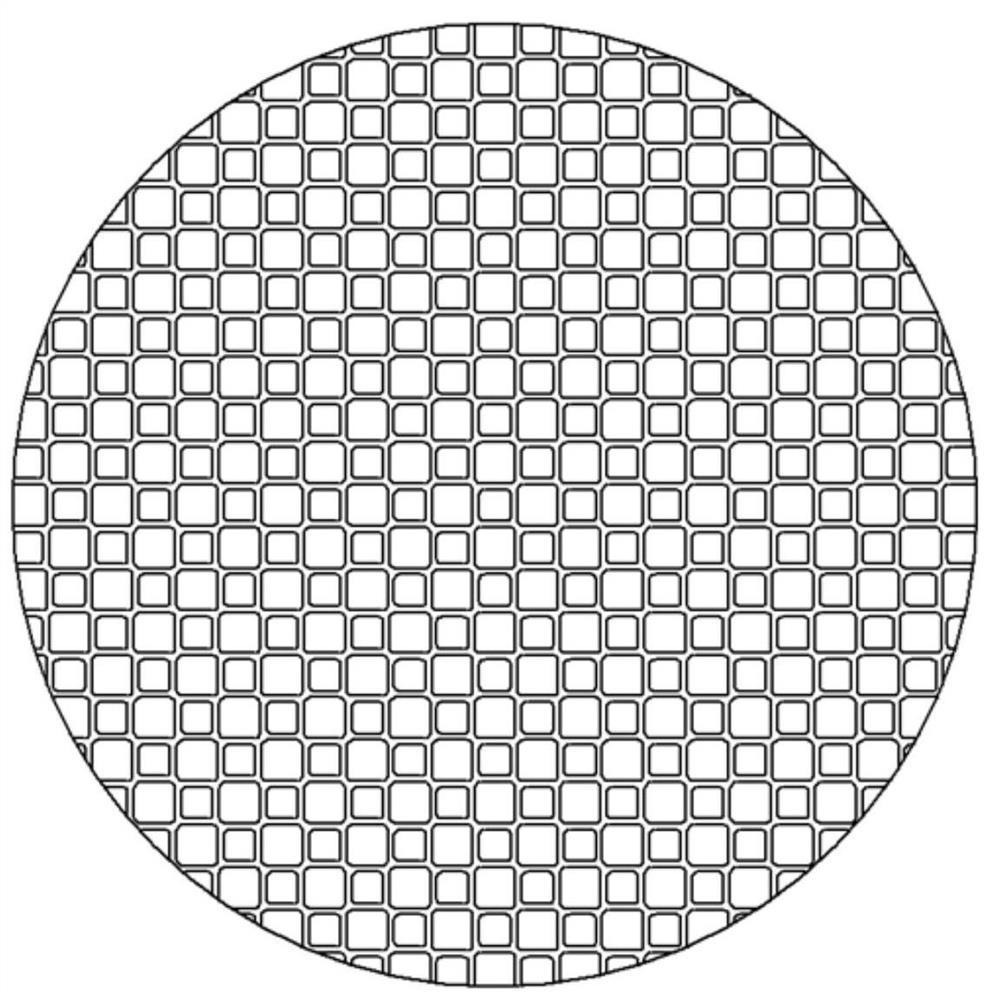

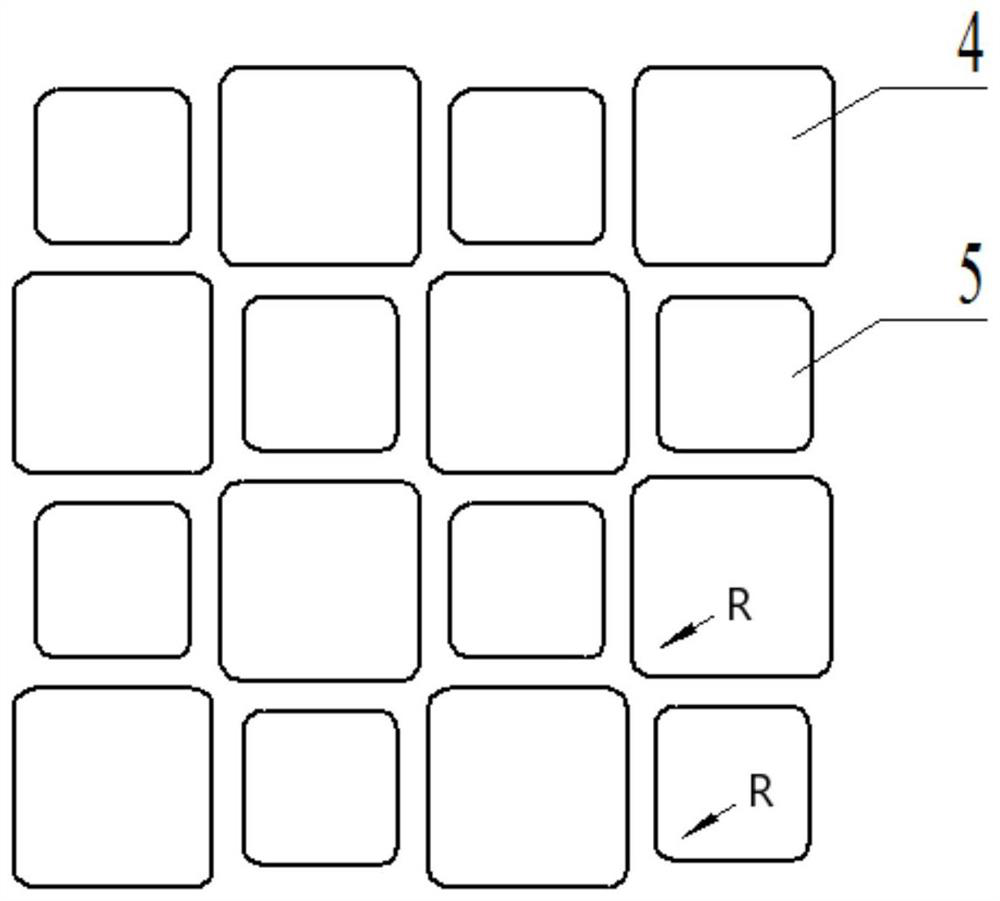

[0025] The after-treatment soot particulate filter for diesel vehicles is a DPF honeycomb ceramic carrier with an asymmetric structure. The commonly used hole density models of this product are 300-9, 300-7, the model 300-9 is 300 holes / square inch, the product wall thickness is 9mil (0.229mm), the model 300-7 is 300 holes / square inch, the product wall thickness It is 7mil (0.178mm). The product is usually cylindrical, with an end face diameter in the range of 150-330mm and a length in the range of 100-400mm. The commonly used diameter specifications are 7.5” (190.5mm), 9” (228.6mm), 10.5” (266.7mm), 12” (304.8mm), 13” (330.2mm). The length ratio of the square hole side of the hole is 1.2~1.4, preferably 1.25~1.35, such as figure 1 shown.

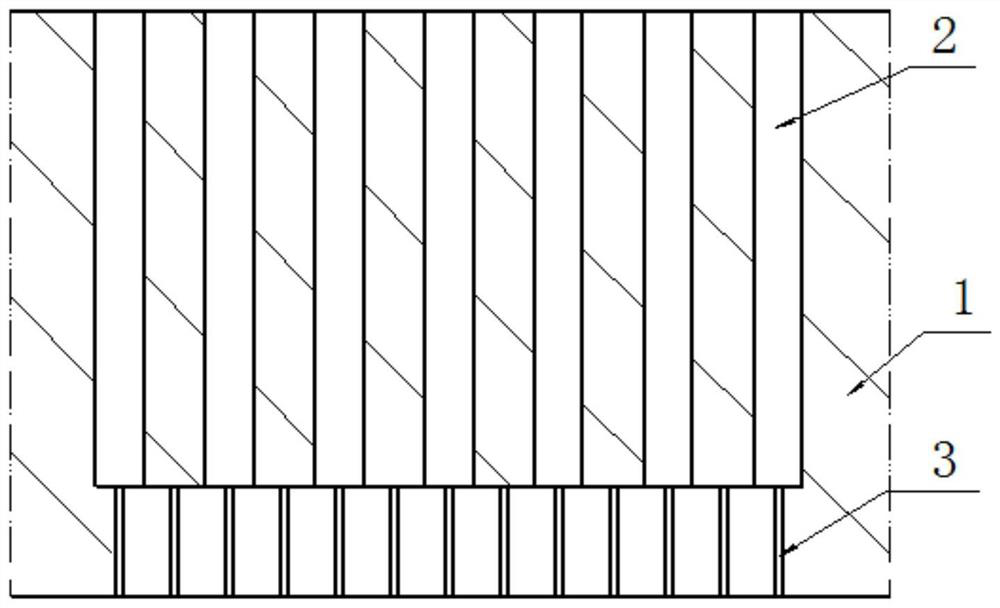

[0026] The asymmetric DPF mold used to prepare the DPF honeycomb ceramic carrier with the above asymmetric structure, the main st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fillet | aaaaa | aaaaa |

| Fillet | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com