Ceramic supporting disc sleeving equipment for squirrel-cage electrothermal radiation tube production

An electrothermal radiation, squirrel-cage technology, applied in metal processing equipment, heating element shape, metal processing and other directions, can solve the problems of affecting product quality, low packaging efficiency, heating element bumping, damage, etc., to increase the scope of application , The effect of shortening the time-consuming and improving the efficiency of assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

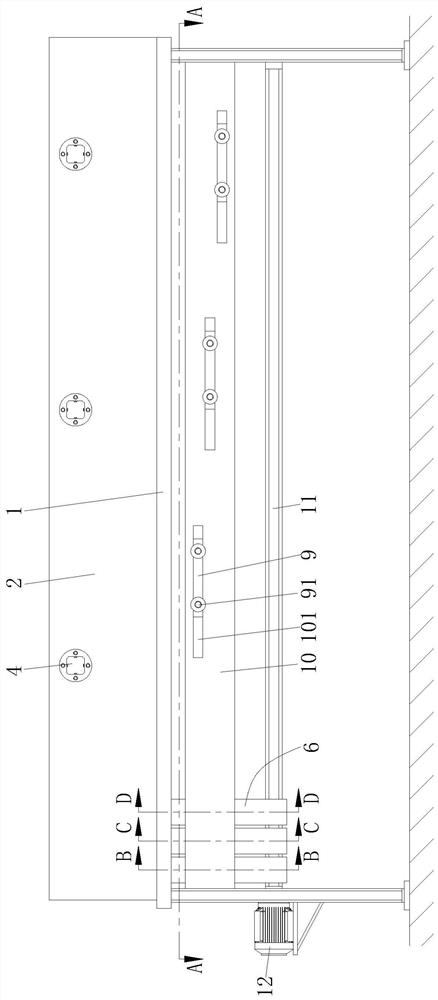

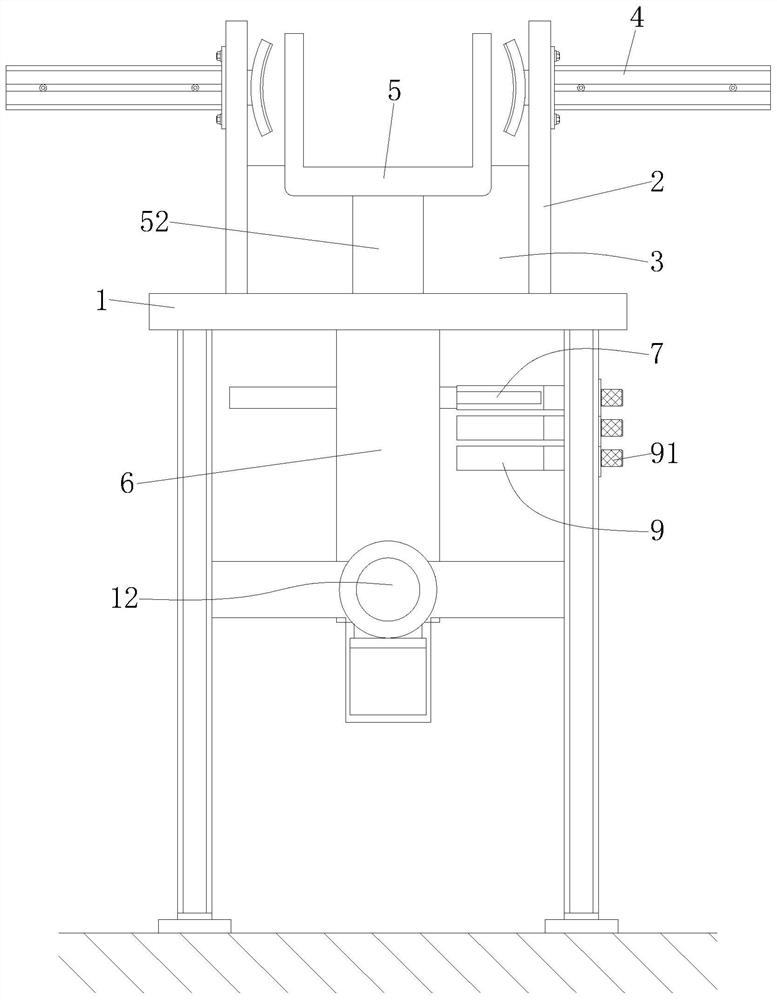

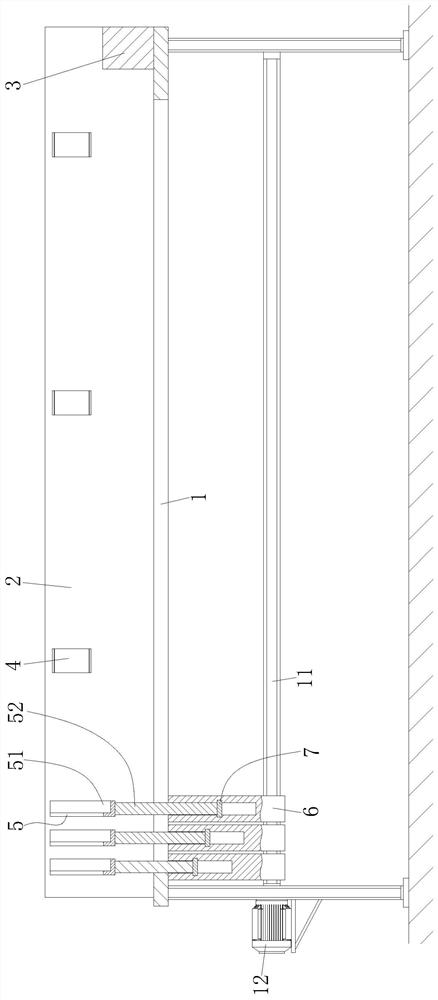

[0030] Such as Figure 1 to Figure 10 As shown in the figure, a squirrel-cage type electric heating radiant tube production ceramic support disc assembly equipment includes an operation table 1, and the table top of the operation table 1 is symmetrically provided with two side baffles 2 distributed along the left and right directions. Between the side baffles 2 and on the right side of the console 1, a support seat 3 is provided, and several groups of cylinder grippers 4 for clamping and positioning the heating element are arranged symmetrically on the two side baffles 2;

[0031] Between the two side baffles 2 and on the left side of the table top of the console 1, there are a number of sleeve holders 5 for placing the ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com