Color gradient injection molding process for packaging bottle

A color gradient and packaging bottle technology, applied in applications, home appliances, and other home appliances, can solve problems such as low color fastness and easy discoloration of plastic pipes, and achieve the effects of prolonging the blending time, improving color fading, and having a flawless surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

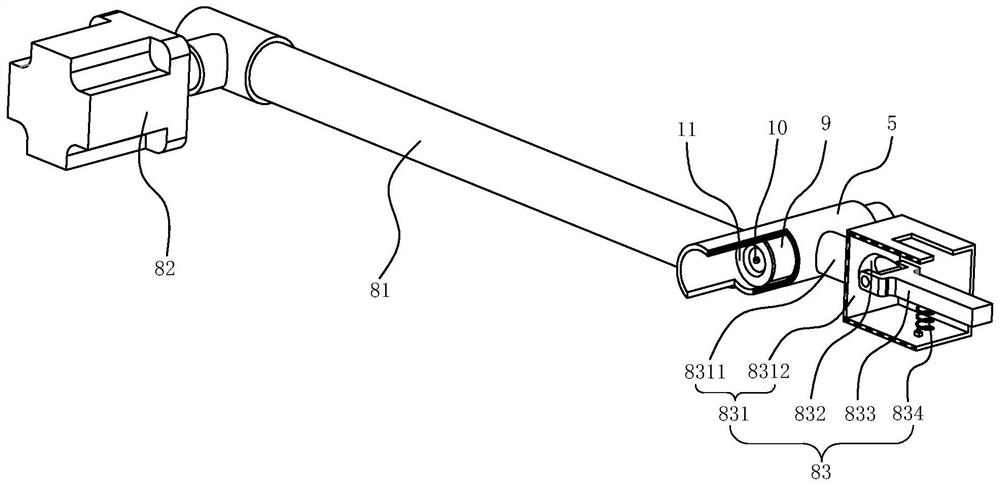

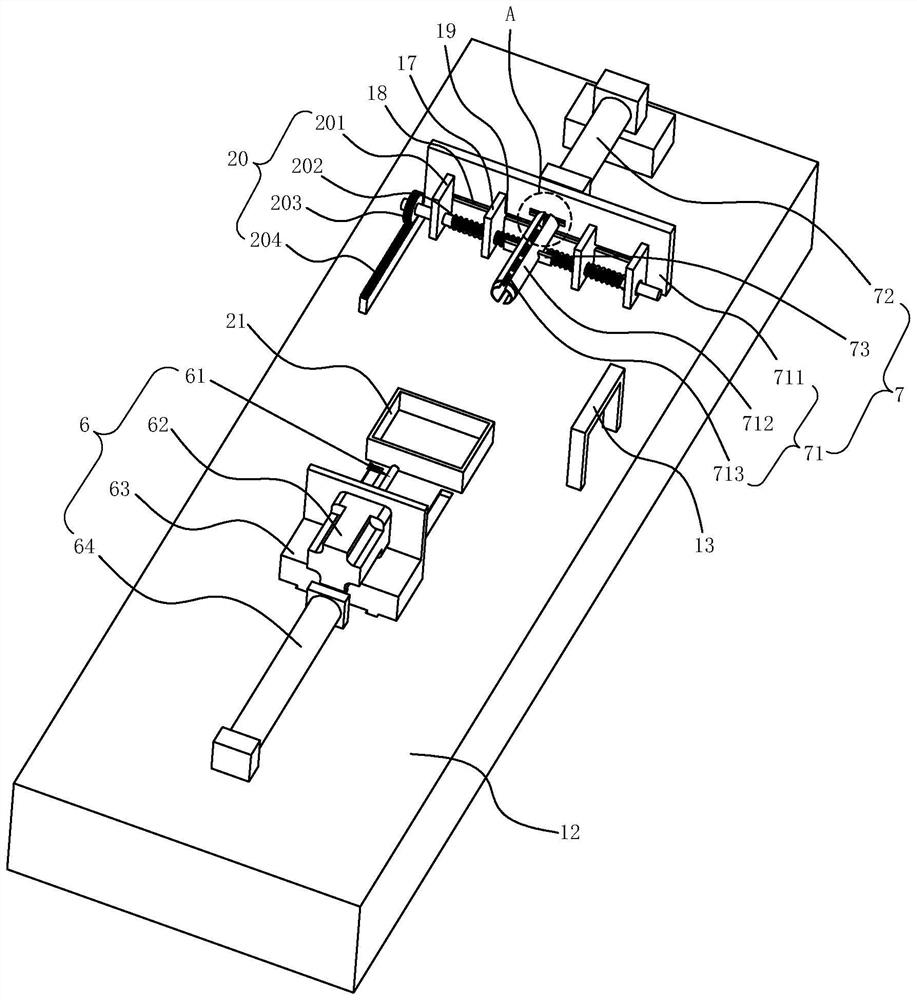

[0049] The following is attached Figure 1-7 The application is described in further detail.

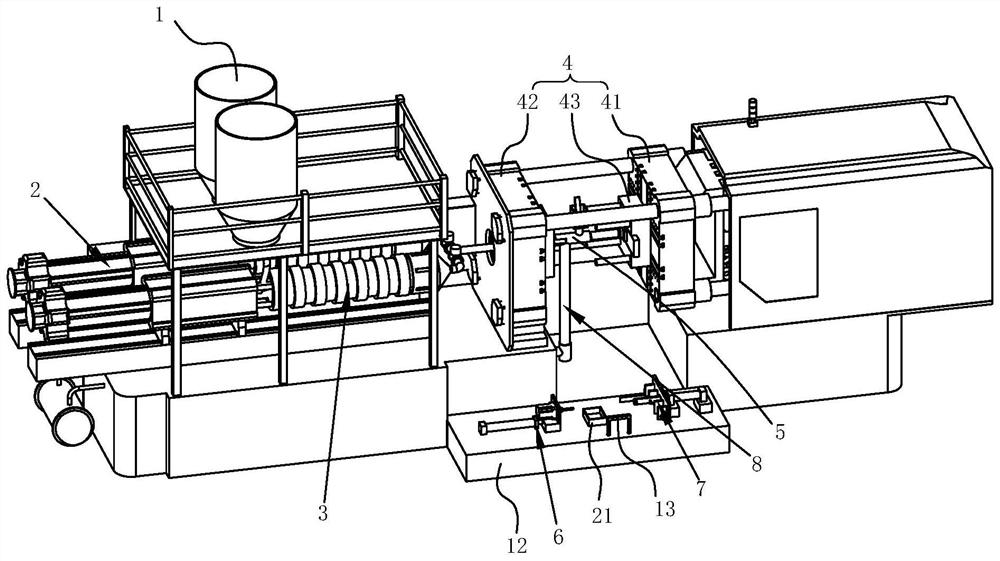

[0050] The embodiment of the present application discloses a color gradient injection molding process for packaging bottles. refer to figure 1 A color gradient injection molding process for packaging bottles comprises the following steps:

[0051] S1. Prepare plastic raw materials of two different colors.

[0052] S2. Import plastic raw materials of two different colors into different lower hoppers 1 respectively, and transport the plastic raw materials of two colors to two injection systems 2 respectively through different lower hoppers 1; the discharge end of each injection system 2 is connected to the Electronic valves are arranged between the feeding ends of the injection pipes, and the injection system 2 adopts a screw type injection system 2 .

[0053] S3. The heating system 3 is wrapped around the screw pusher of the injection system 2. The heating system 3 heats the two i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com