Method for preparing curing agent from concrete waste residues

A technology of concrete waste residue and curing agent, which is applied in chemical instruments and methods, applications, fertilizer mixtures, etc., can solve the problem of less recovery of cementitious material particles, and achieve the realization of resource reuse, high-efficiency curing, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

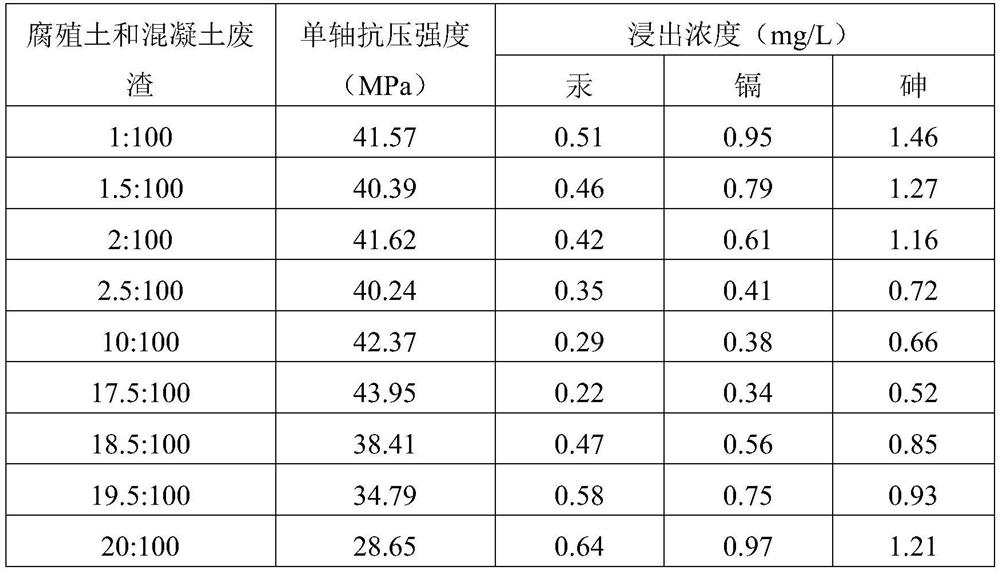

[0019] Influence of the mass ratio of humus soil and concrete waste residue on the performance of the prepared curing agent

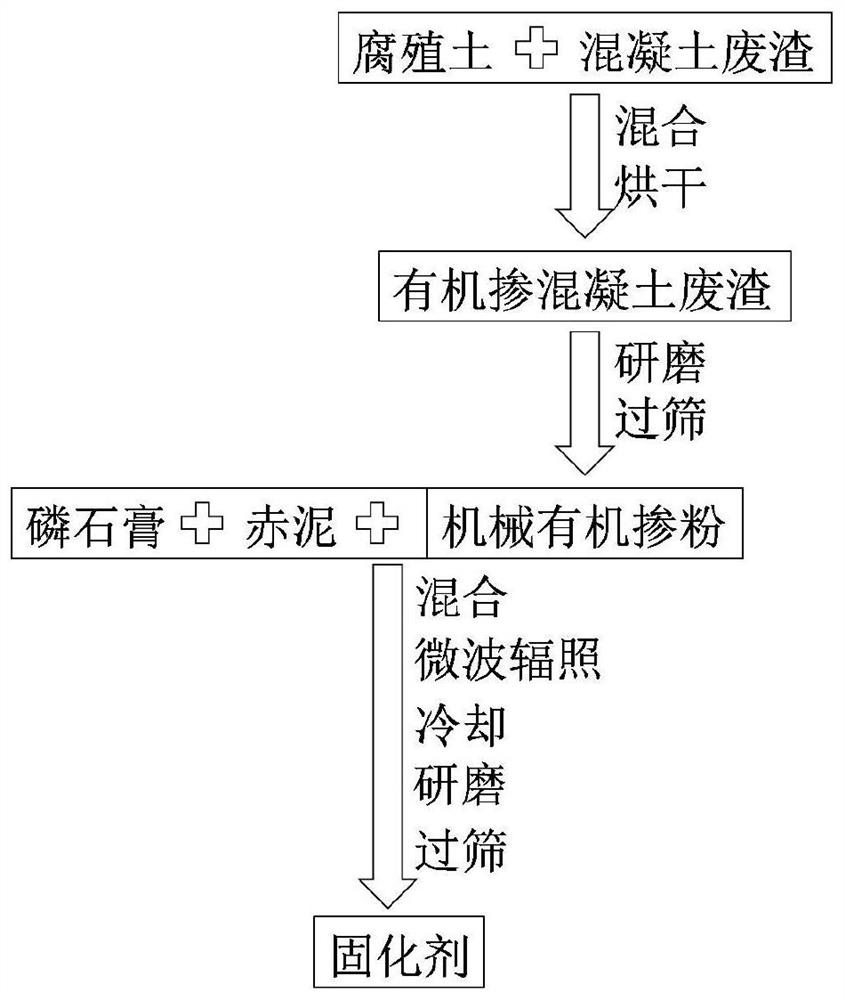

[0020] Preparation of curing agent: as figure 1 As shown, according to the mass ratio of humus soil and concrete waste residue is 1:100, 1.5:100, 2:100, 2.5:100, 10:100, 17.5:100, 18.5:100, 19.5:100, 20:100 respectively Mix the two, and then dry at 50°C to obtain organic-mixed concrete waste, grind the organic-mixed concrete waste for 0.5 hours, pass through a 200-mesh sieve, and the sieved part obtained is mechanical organic-mixed powder; according to phosphogypsum, red mud The mass ratio of mechanical and organic mixed powder is 2.5:5:100. Mix the three, and then place them in a microwave vacuum atmosphere sintering furnace for activation. After activation, cool to room temperature. Take out the activated mixture and grind it into powder. Mesh sieve, the sieved part obtained is the curing agent, wherein the activation time is 1 hour, and the activati...

Embodiment 2

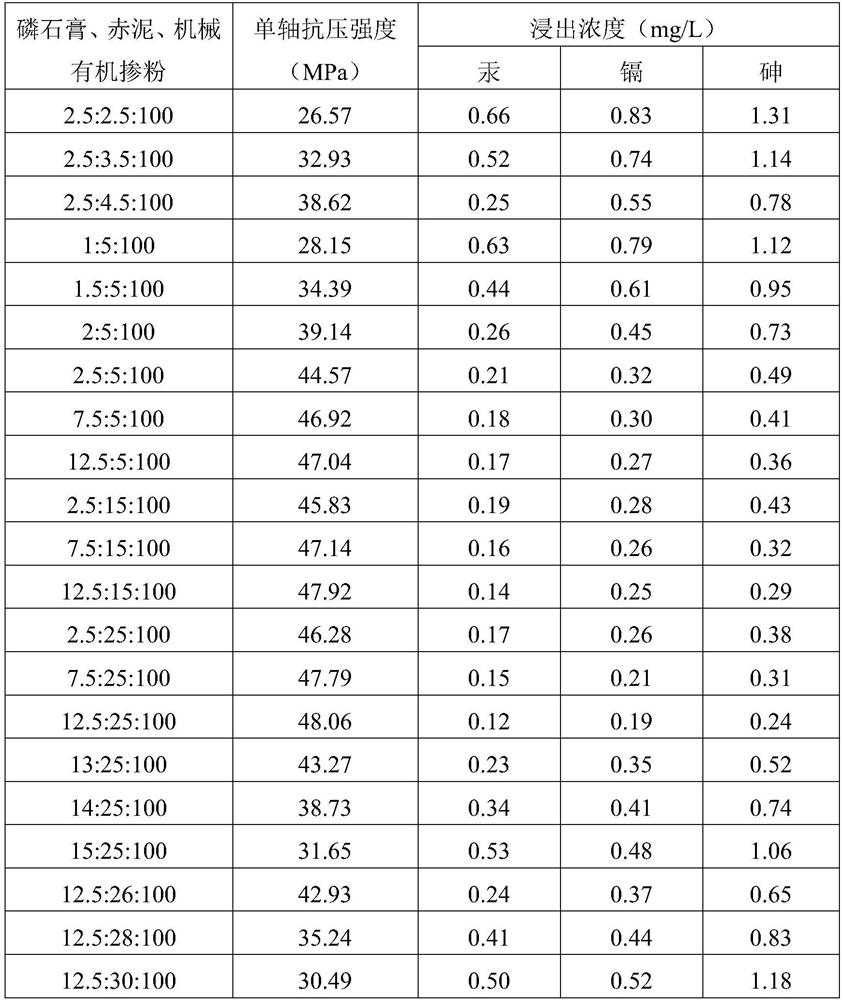

[0029] Effect of mass ratio of phosphogypsum, red mud and mechanical organic powder on the performance of the prepared curing agent

[0030] Preparation of curing agent: Mix humus and concrete waste residue at a mass ratio of 17.5:100, then dry at 100°C to obtain organic-mixed concrete waste, grind organic-mixed concrete waste for 2.5 hours, pass through 300 mesh Sieve, the sieved part obtained is mechanical organic mixed powder; according to the mass ratio of phosphogypsum, red mud and mechanical organic mixed powder is 2.5:2.5:100, 2.5:3.5:100, 2.5:4.5:100, 1:5: 100, 1.5:5:100, 2:5:100, 2.5:5:100, 7.5:5:100, 12.5:5:100, 2.5:15:100, 7.5:15:100, 12.5:15:100, 2.5:25:100, 7.5:25:100, 12.5:25:100, 13:25:100, 14:25:100, 15:25:100, 12.5:26:100, 12.5:28:100, 12.5: Mix the three at a ratio of 30:100, then place them in a microwave vacuum atmosphere sintering furnace for activation, cool to room temperature after activation, take out the activated mixture and grind it into powder, pa...

Embodiment 3

[0037] Influence of Microwave Heating Activation Time on the Properties of the Prepared Curing Agent

[0038] Preparation of curing agent: Mix humus and concrete waste residue at a mass ratio of 17.5:100, then dry at 150°C to obtain organic-mixed concrete waste, grind organic-mixed concrete waste for 4.5 hours, pass through 400 mesh Sieve, the sieved part obtained is mechanical organic mixed powder; according to the mass ratio of phosphogypsum, red mud and mechanical organic mixed powder is 12.5:25:100, the three are mixed, and then placed in a microwave vacuum atmosphere sintering furnace for activation. Cool to room temperature after activation, take out the activated mixture and grind it into powder, pass through a 400-mesh sieve, and the sieved part obtained is the curing agent, and the activation time is 0.5 hours, 0.7 hours, 0.9 hours, 1 hour, 2.5 hours, 4 hours, 4.5 hours, 5 hours, 6 hours, the activation temperature is 1000°C.

[0039] The heavy metal contaminated soi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com