Disassembly-free composite formwork and construction technology thereof

A technology of composite formwork and non-demolition formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, walls, etc., can solve the problems of non-demolition formwork such as grout leakage, and achieve improved construction efficiency and good airtightness , The effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

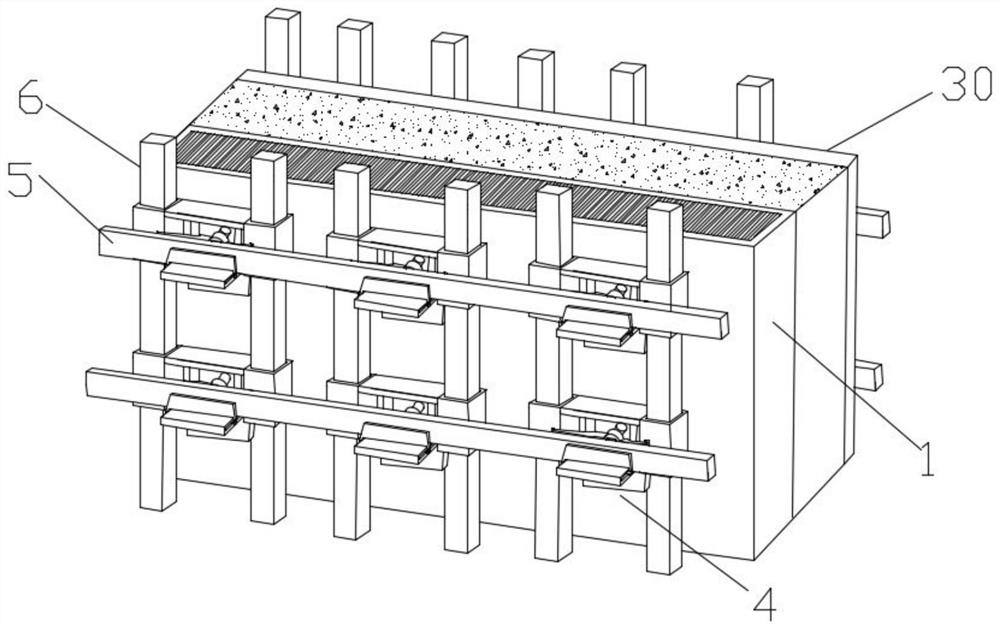

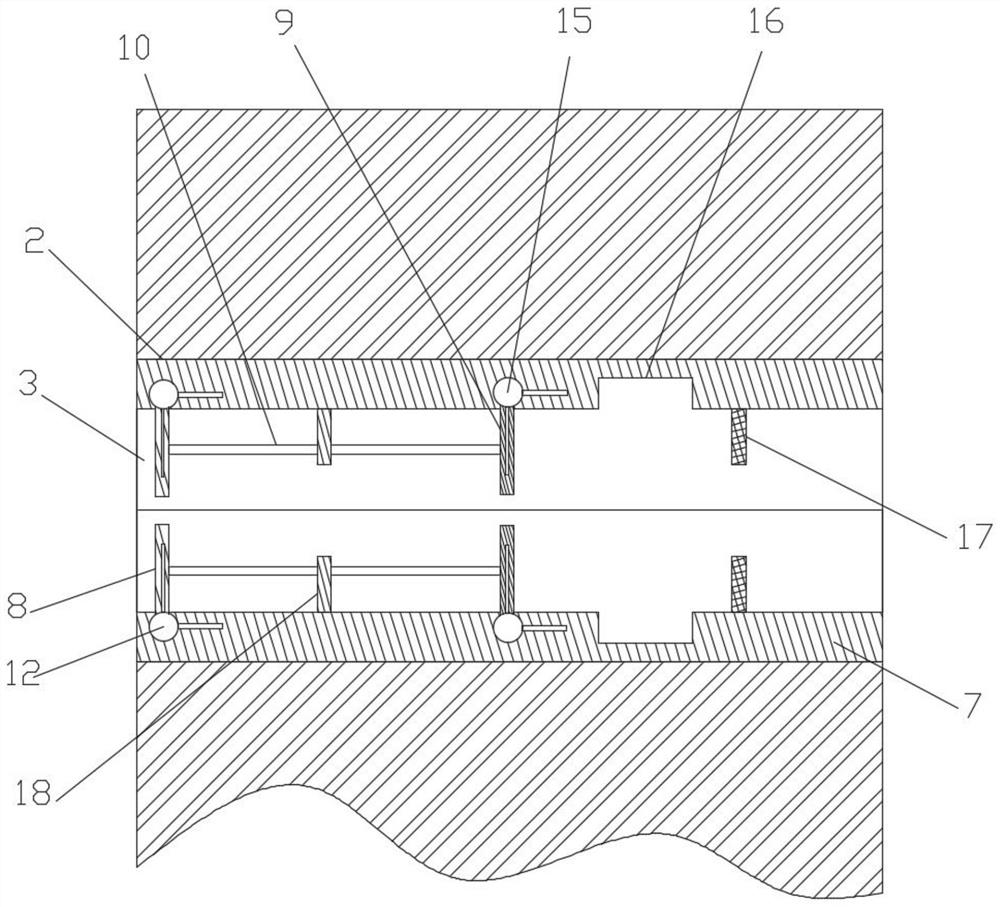

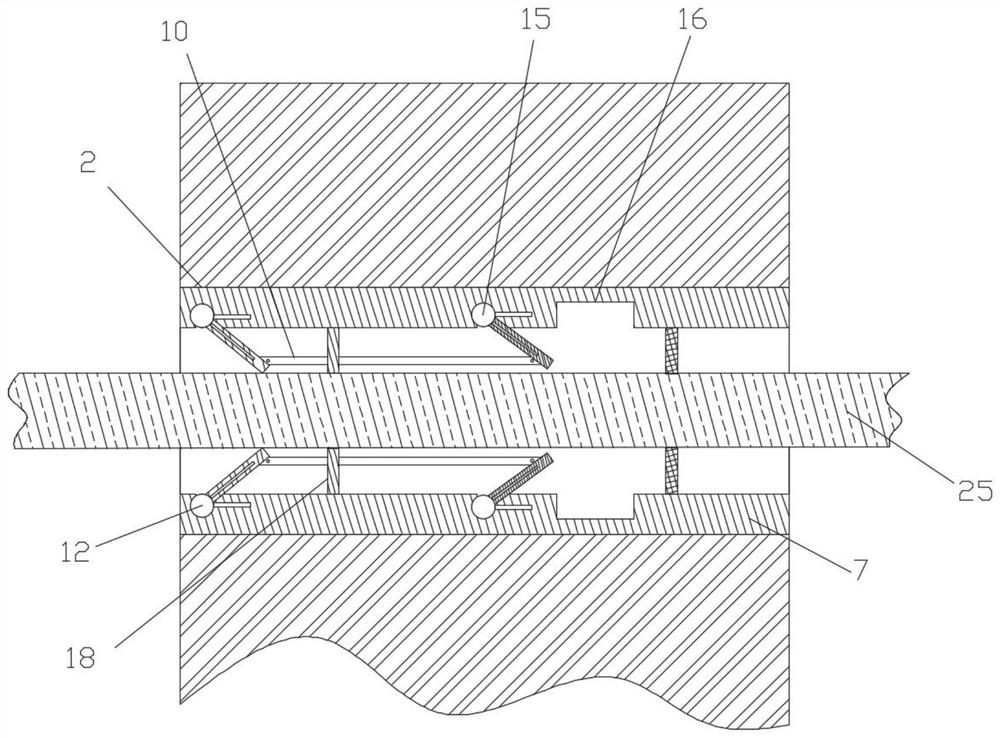

[0037] like Figure 1 to Figure 7 As shown, it is an embodiment of the present invention, a non-dismantling composite formwork, including a dismantling-free formwork 1, a connecting hole 2 is opened on the non-dismantling formwork 1, and a one-way member 3 is installed in the connecting hole 2, and the one-way member 3 is suitable for one-way passage from the outside to the inside without dismantling the formwork 1, the connection hole 2 is suitable for installing the connector when pouring concrete, the outer end of the connector is installed with an auxiliary frame 4, and the auxiliary frame 4 is suitable for installing the main flute 5 and secondary flute 6.

[0038] The one-way member 3 includes a cylinder body 7. A one-way plate 8 and a bent plate 9 are installed in both ends of the cylinder body 7. The one-way plate 8 is connected to the cylinder body 7 in rotation, and the bent plate 9 is fixedly connected to the cylinder body 7. The folding plate 9 is suitable for rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com