Press pump-controlled hydraulic system and its control method

A hydraulic system and press technology, which is applied to the pump-controlled hydraulic system of the press and its control field, can solve the problems of unbalanced oil in a pump-controlled asymmetric cylinder, improve the anti-pollution capability and reliability, achieve high stable operation, The effect of improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

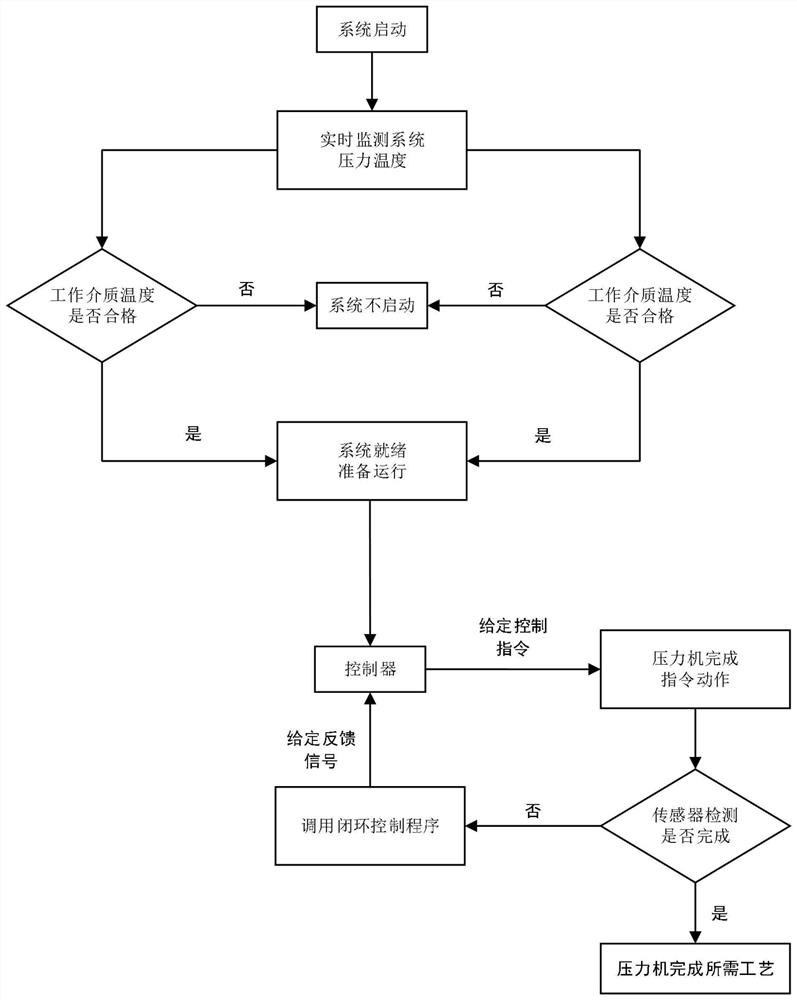

[0030] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

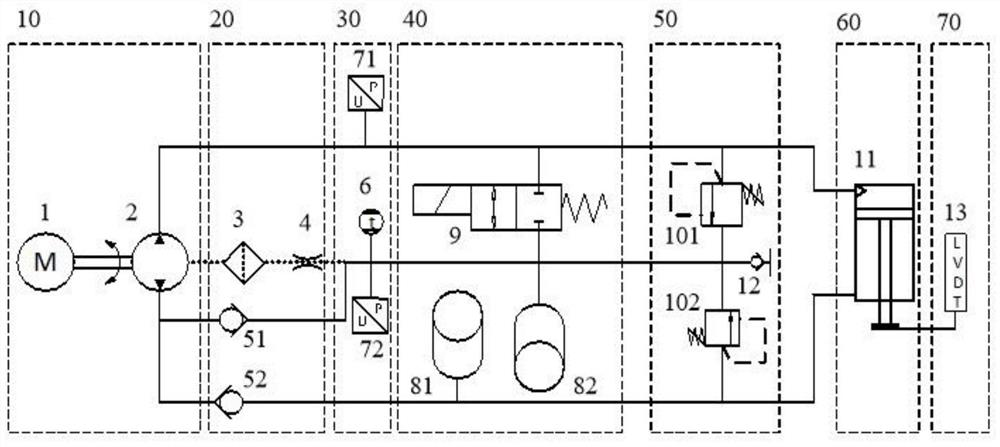

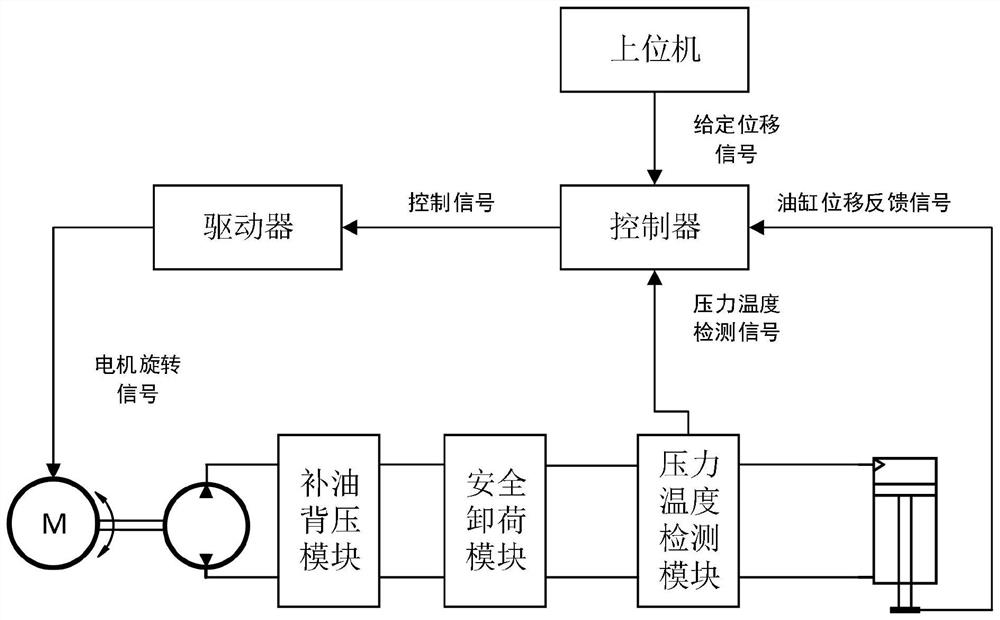

[0031] The press pump control hydraulic system provided by the invention, such as figure 1 As shown, it includes a power module 10, a one-way throttling module 20, a pressure and temperature detection module 30, an oil supplement back pressure module 40, a safety overflow module 50, an actuator module 60, a displacement detection module 70 and a The connected hydraulic valve block 13, the power module 10 is connected to the upper surface of the hydraulic valve block 13, the one-way throttle module 20 is connected to the left surface of the hydraulic valve block 13, and the pressure and temperature detection module 30 is connected to the left surface of the hydraulic valve block 13 and the right surface, the supplementary oil back pressure module 40 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com