Low-noise building material processing machine and assembly type noise reduction system

A technology of processing machinery and noise reduction system, applied in the direction of mechanical equipment, sounding equipment, transmission devices, etc., can solve the problems of insignificant noise reduction treatment effect, difficult flexible shrinkage adjustment, poor traffic effect, etc., to ensure air smoothness , the effect of guaranteeing the sameness and guaranteeing synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

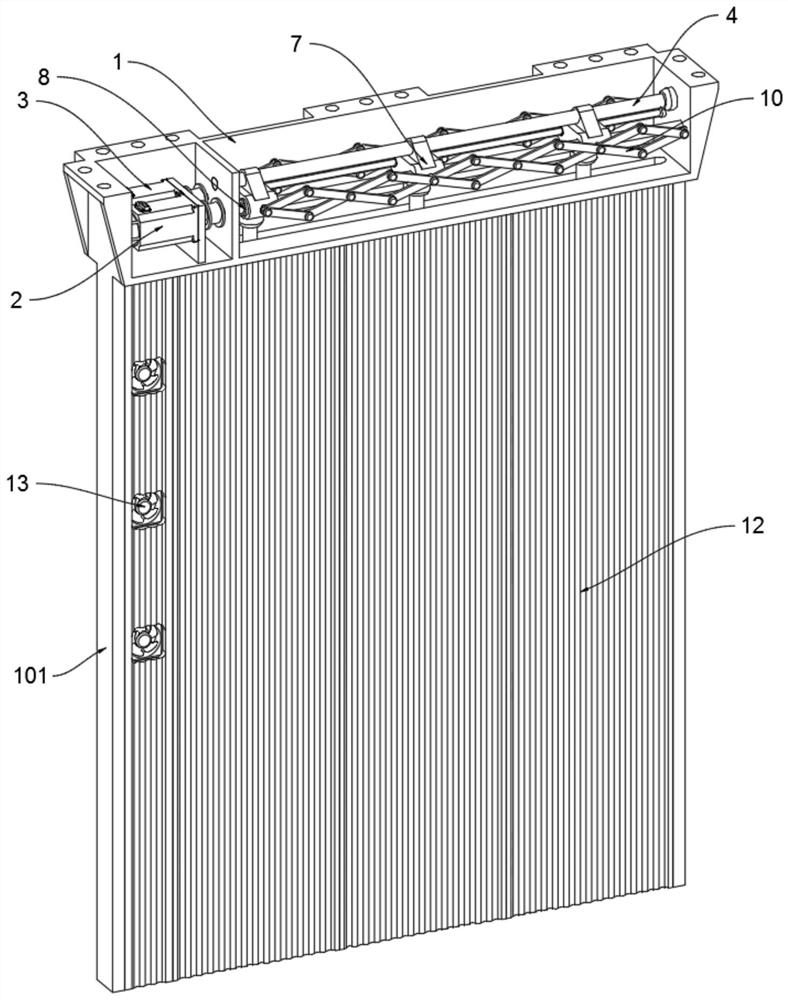

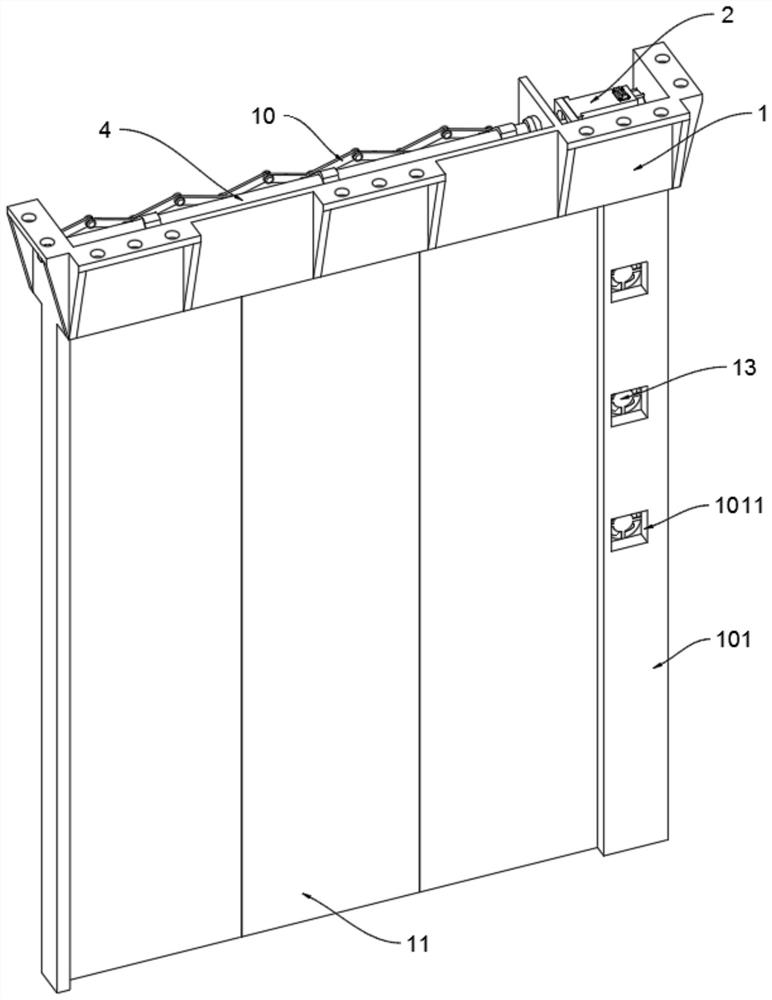

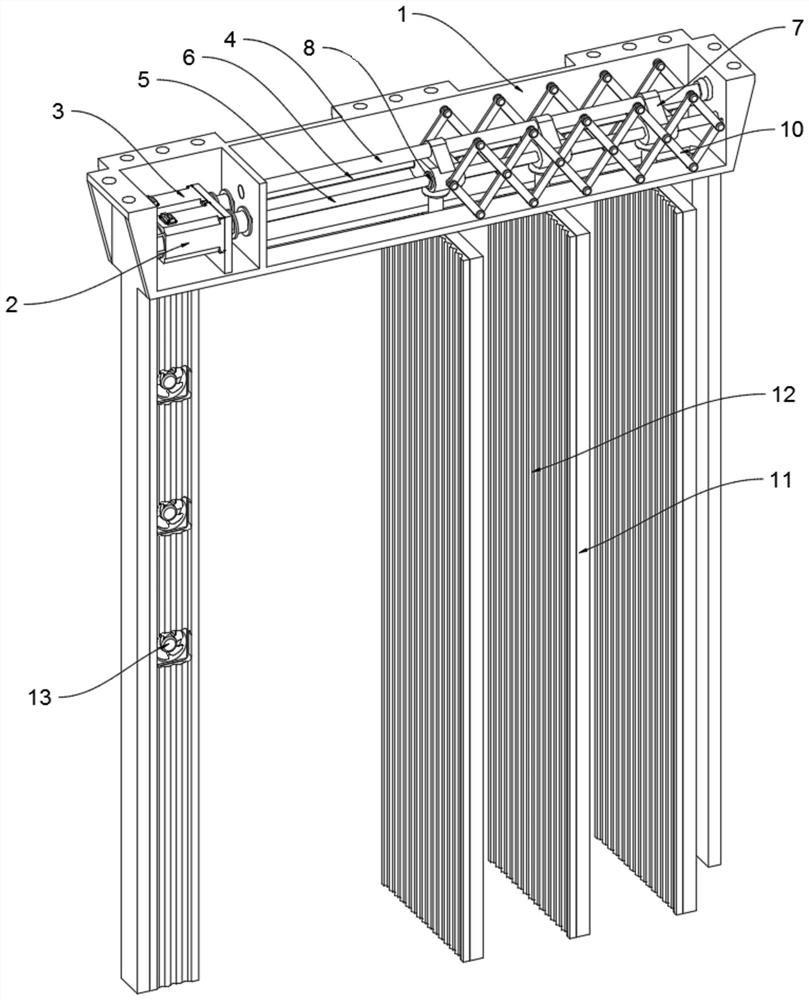

[0039] as attached figure 1 To attach Figure 6 Shown:

[0040] The present invention provides a low-noise building material processing machine and an assembled noise reduction system, including an assembly seat 1, a guide rod 4, a lead screw 5, a double key shaft 6 and a baffle 11;

[0041] The inside of the assembly seat 1 is hollow, and the left end of the assembly seat 1 is equipped with a moving motor 2, and the moving motor 2 is connected to the left end of the lead screw 5;

[0042] The guide slide bar 4 is installed in the assembly seat 1, and the guide slide bar 4 is connected with the top drive member 7;

[0043] The lead screw 5 is installed in the assembly seat 1, and the lead screw 5 runs through the top drive member 7;

[0044] A rotating motor 3 is installed on the left end of the assembly seat 1, and the rotating motor 3 is connected to the left end of the double key shaft 6

[0045] The double key shaft 6 is installed in the assembly seat 1, and the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com