Electromechanical product system or equipment real-time fault diagnosis method based on width learning

A technology for electromechanical products and learning systems, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

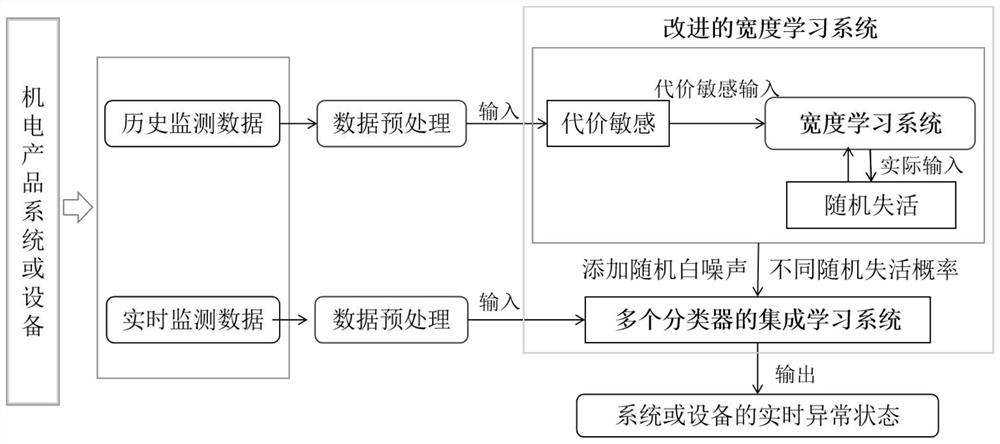

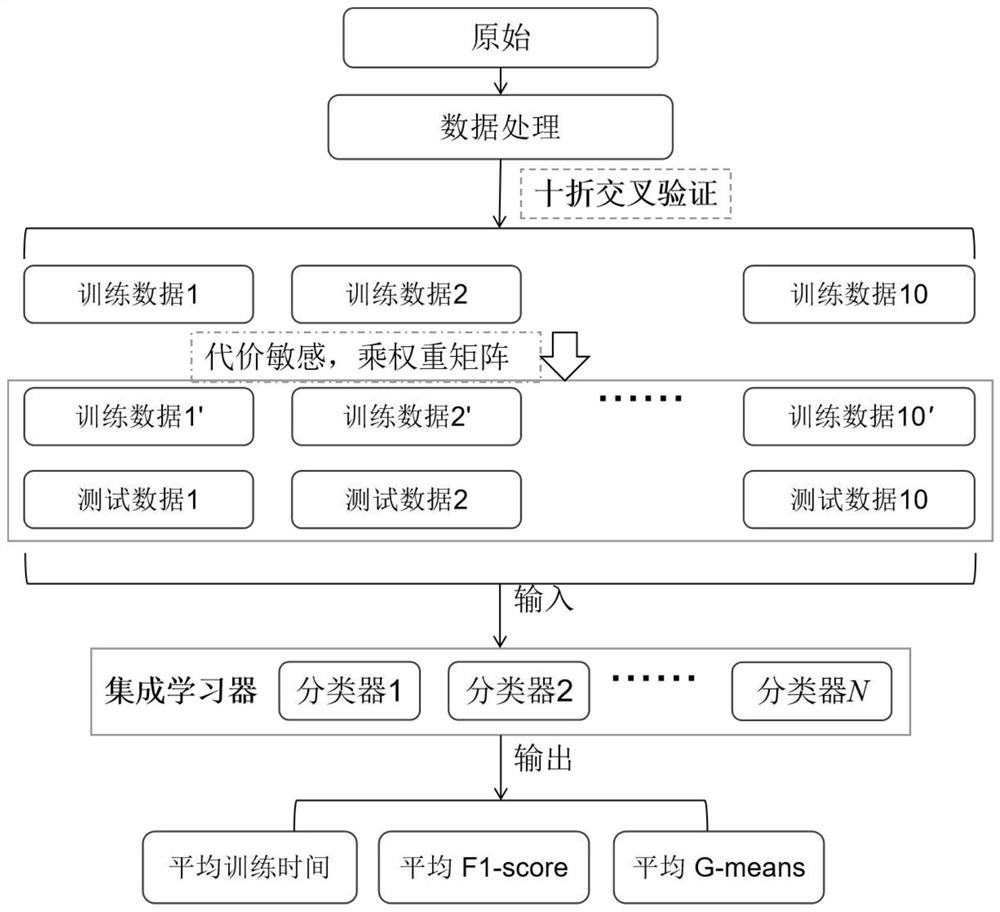

[0048] Embodiments of the present invention provide a real-time fault diagnosis method for electromechanical product systems or equipment based on breadth learning, such as figure 1 As shown, the specific steps include:

[0049] Step 1: Collect the fault status of electromechanical product systems or equipment and related monitoring data for a period of time as historical monitoring data;

[0050] In general, the collected system or equipment fault status monitoring data is heterogeneous data, including continuous features, discrete features and signal features.

[0051] Step 2: Perform data preprocessing on historical monitoring data, including missing values, outliers, dimensional gaps, and digital processing, etc., to obtain the preprocessed data set [X, Y]. The monitoring data can be converted into numerical data by extracting key indicators of signal characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com