Multi-station machined part clamping device capable of removing scrap iron for combined machining

A clamping device and combined processing technology, which is applied to metal processing machinery parts, positioning devices, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

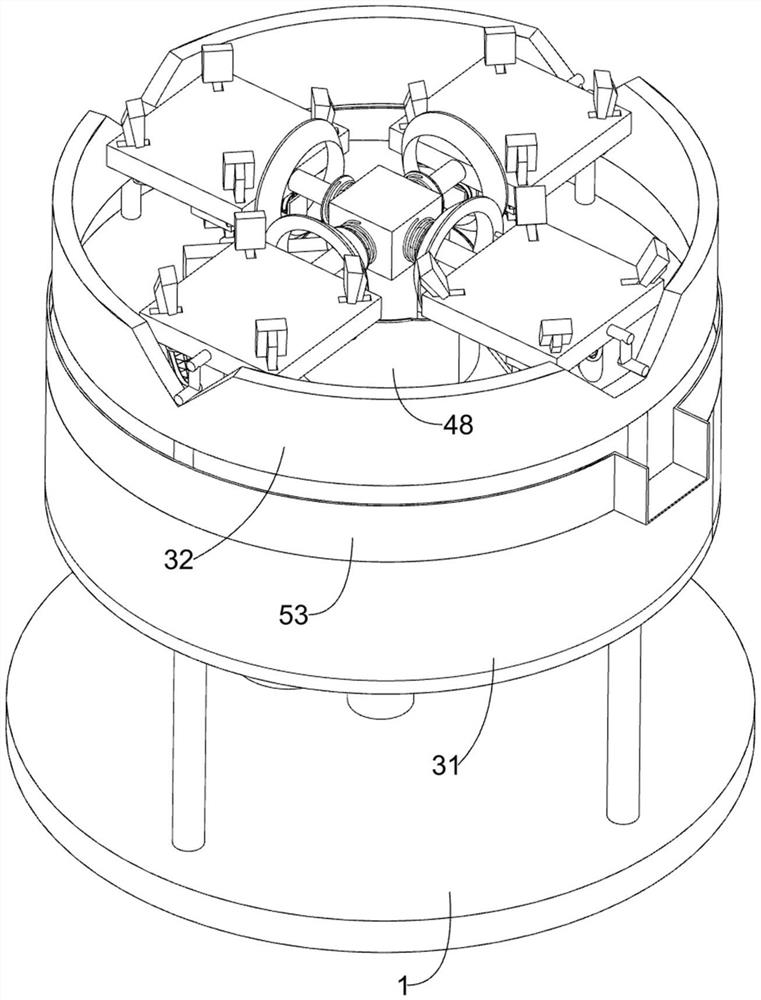

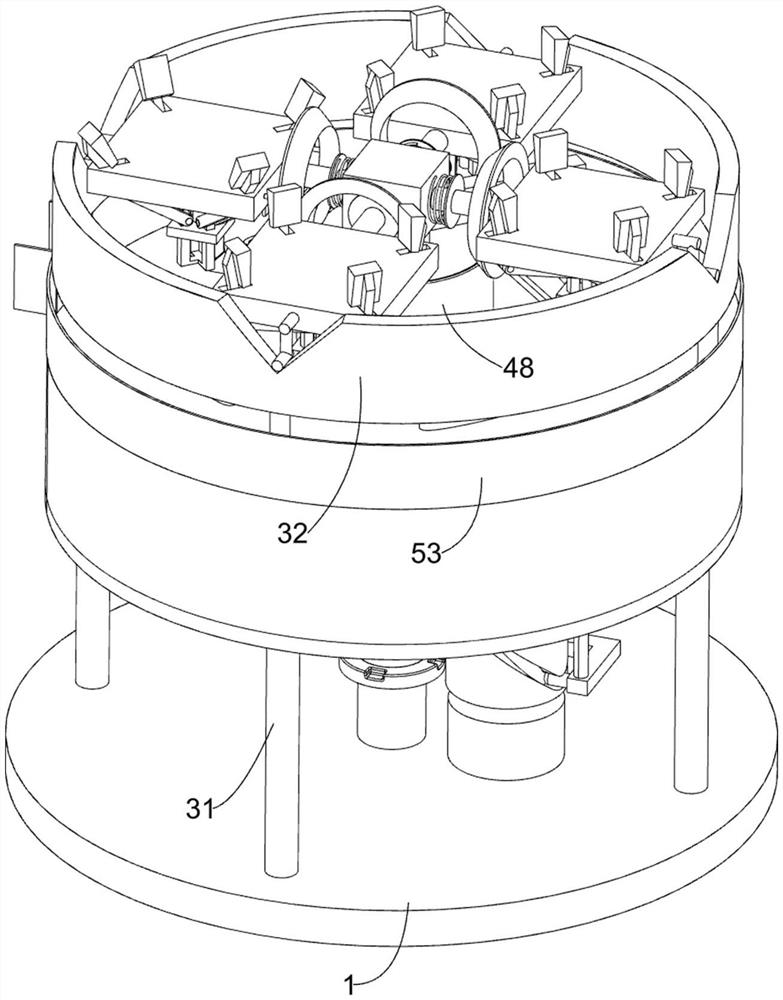

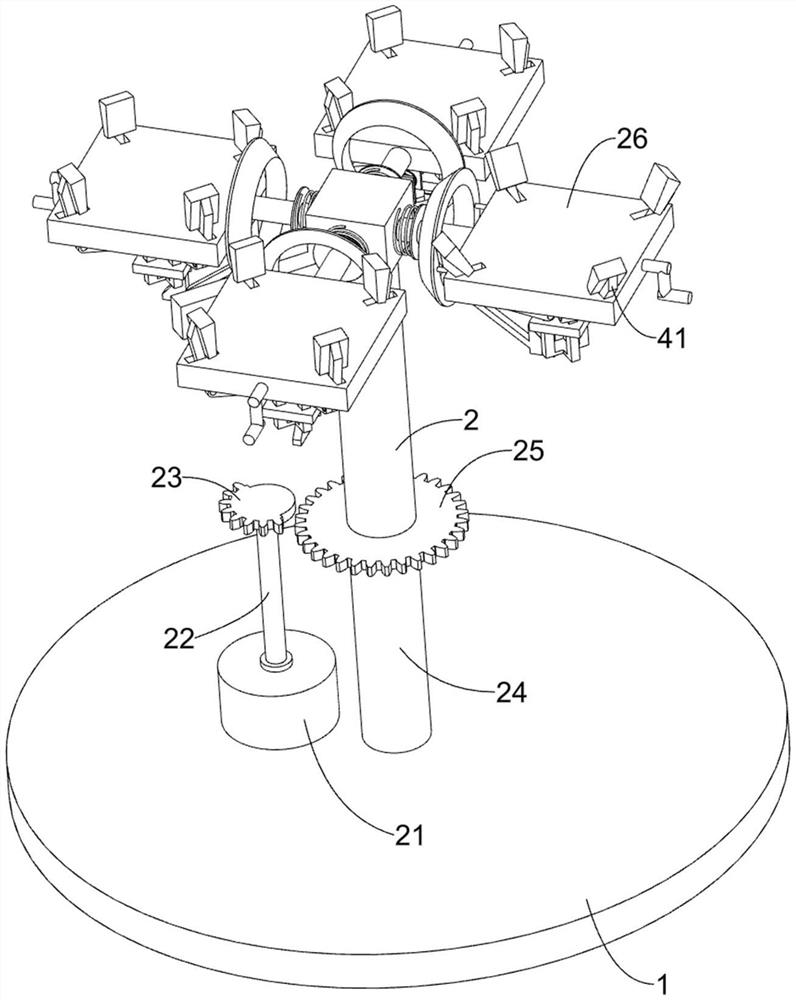

[0026] A multi-camera work piece clamping device capable of removing iron filings for combined processing, such as Figure 1-6 As shown, it includes a supporting base frame 1, a rotating assembly 2, an overturning assembly 3 and a clamping device 4. The rotating assembly 2 is fixedly installed on the supporting base frame 1, and the top surface of the supporting base frame 1 is provided with a tool for turning over the workpiece. The turning assembly 3 and the clamping device 4 for clamping the workpiece are arranged on the rotating assembly 2 .

[0027] The rotating assembly 2 includes a motor 21, a rotating shaft 22, a missing gear 23, a turret 24, a spur gear 25, and a placement frame 26. The top surface of the support chassis 1 is fixedly equipped with a motor 21, and the output shaft of the motor 21 is welded with a rotating shaft 22. , the top of the rotating shaft 22 away from the motor 21 is fixedly connected with a missing gear 23, the support chassis 1 is rotatably c...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 7-8 As shown, it also includes a chip removal auxiliary assembly 5, and the support frame 31 is provided with a chip removal auxiliary assembly 5. 521, the guide groove plate 53 and the air outlet pipe 54 with the sieve plate, the rotating shaft 22 is provided with a slotted cylinder 51, the pushing ring 52 is connected in the support frame 31 in a liftable manner, and the pushing ring 52 is used for The gas in the support frame 31 is extruded, and the bottom surface of the pushing ring 52 is provided with a second clamp frame 521, and the second clamp frame 521 is limitedly matched with the slotted cylinder 51, and the slotted cylinder 51 is used to push the second column frame. The column frame 521 and the push ring 52 reciprocate up and down, the guide groove plate 53 is fixedly installed on the support frame 31, and the support frame 31 is provided with two pairs of air outlet pipes 54 with sieve plates, and the air outlet ...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 7-8 As shown, it also includes an anti-deviation assembly 6, which is arranged on the turret 24. The anti-deviation assembly 6 is used to prevent the turret 24 and the device on it from deflecting. The anti-deviation assembly 6 includes a slot Ring 61 and spacer 62, slotted ring 61 is welded on the turret 24, spacer 62 is arranged on the second card column frame 521, spacer 62 at least a part is arranged in the groove of slotted ring 61, limit The bit frame 62 is used for clamping the slotted ring 61 .

[0038] When the second clamp frame 521 moved upwards, the second clamp frame 521 would drive the spacer 62 to move upward, and the spacer 62 would no longer block the slotted ring 61, so that the turret 24 and its upper device could rotate, After the workpiece position is switched, when the workpiece is being processed, the limit frame 62 just blocks the slotted ring 61 to prevent the turret 24 and its upper device from deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com