Automatic charging platform of high-capacity power supply device for underground coal mine

A power supply device and automatic charging technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of short lifespan of the power supply device, cumbersome and cumbersome charging process, avoid the risk of being squeezed, and reduce labor intensity. , the effect of simplifying the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

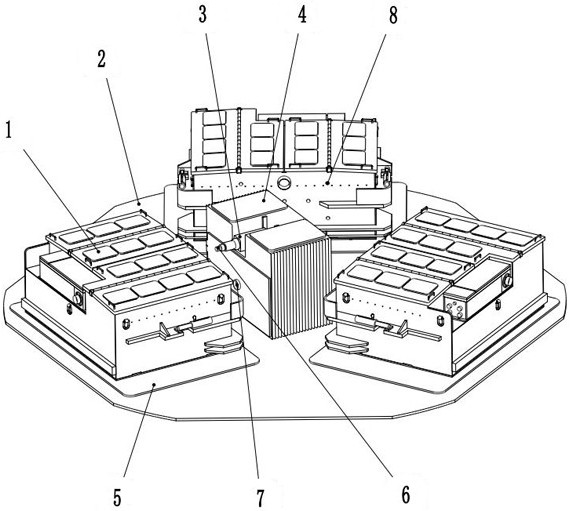

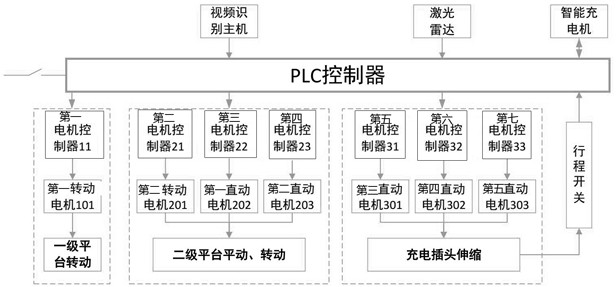

[0025] Such as figure 1 , figure 2 As shown, the embodiment of the present invention is an automatic charging platform for a large-capacity power supply device for underground coal mines, including: an intelligent charger 4, on which a video recognition host 7, a charging plug expansion mechanism 3 and a laser radar 8 are installed; The first-stage rotating platform 2 is rotatably arranged around the intelligent charger 4; several second-stage platforms 5 are arranged along the circumferential direction of the first-stage rotating platform 2, and are movably connected with the first-stage rotating platform 2; several power supply devices 1, power supply The device 1 is fixed on the secondary platform 5 , and the rear end of the power supply device 1 is provided with a charging port, several feature points and a laser radar 8 . In this embodiment, there are three pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com