Advanced treatment and cyclic utilization method for industrial wastewater

A technology for industrial wastewater and advanced treatment, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problem that the technology cannot meet the target requirements, etc., and achieve convenient operation, improved effect, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

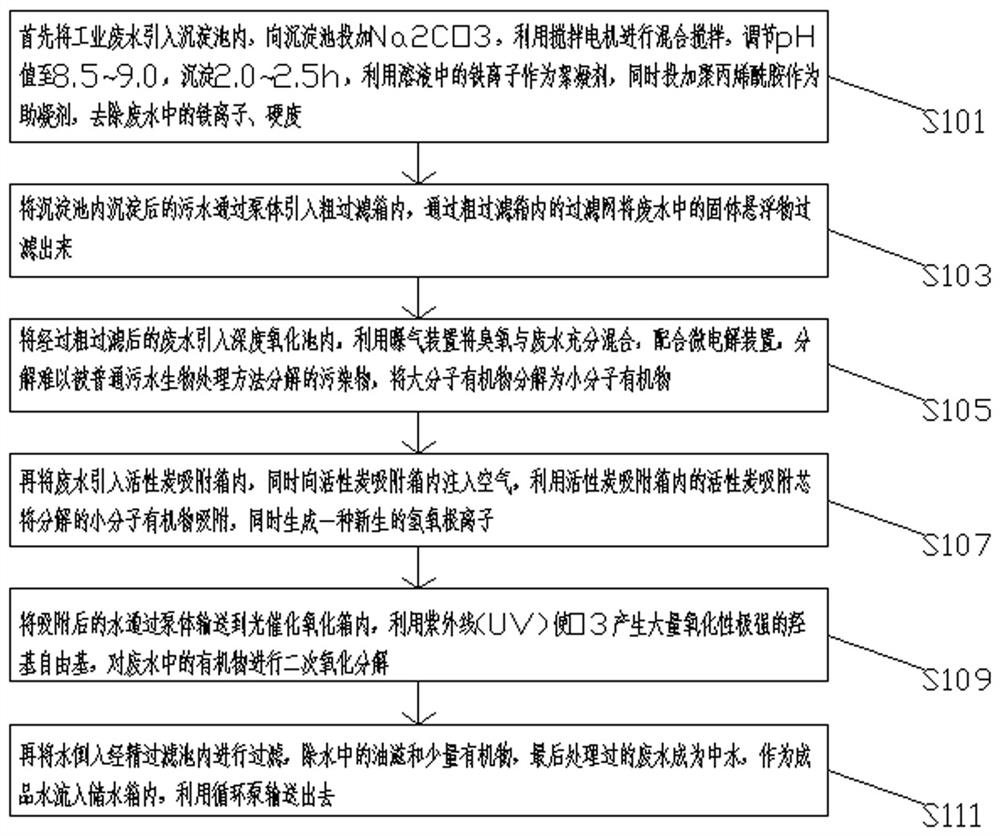

[0024] see figure 1 According to a method for advanced treatment and recycling of industrial wastewater according to an embodiment of the present invention, the specific steps are as follows:

[0025] S1: First introduce industrial wastewater into the sedimentation tank, add Na2CO3 to the sedimentation tank, use the stirring motor to mix and stir, adjust the pH value to 8.5~9.0, settle for 2.0~2.5h, use the iron ion in the solution as a flocculant, and throw in at the same time Add polyacrylamide as a coagulant to remove iron ions and hardness in wastewater;

[0026] S2: The sewage settled in the sedimentation tank is introduced into the coarse filter box through the pump body, and the suspended solids in the wastewater are filtered out through the filter in the coarse filter box;

[0027] S3: Introduce the coarsely filtered wastewater into the deep oxidation tank, use the aeration device to fully mix the ozone with the wastewater, cooperate with the micro-electrolysis device...

Embodiment 2

[0033] Such as figure 1As shown, first introduce industrial wastewater into the sedimentation tank, add Na2CO3 to the flocculation sedimentation tank, use the stirring motor to mix and stir, adjust the pH value to 8.5-9.0, settle for 2.0-2.5 hours, and use the iron ions in the solution as flocculation At the same time, polyacrylamide is added as a coagulant to remove iron ions and hardness in the wastewater, and the sewage precipitated in the sedimentation tank is introduced into the coarse filter box through the pump body, and the wastewater in the wastewater is filtered through the filter in the coarse filter box. The suspended solids are filtered out, and the coarsely filtered wastewater is introduced into the deep oxidation tank, and the ozone is fully mixed with the wastewater by the aeration device, and the micro-electrolysis device is used to decompose the pollutants that are difficult to be decomposed by ordinary sewage biological treatment methods, and the macromolecul...

Embodiment 3

[0035] Such as figure 1 As shown, first introduce industrial wastewater into the sedimentation tank, add Na2CO3 to the flocculation sedimentation tank, use the stirring motor to mix and stir, adjust the pH value to 8.5-9.0, settle for 2.0-2.5 hours, and use the iron ions in the solution as flocculation At the same time, polyacrylamide is added as a coagulant to remove iron ions and hardness in the wastewater, and the sewage precipitated in the sedimentation tank is introduced into the coarse filter box through the pump body, and the wastewater in the wastewater is filtered through the filter in the coarse filter box. The suspended solids are filtered out, and the coarsely filtered wastewater is introduced into the deep oxidation tank, and the ozone is fully mixed with the wastewater by the aeration device, and the micro-electrolysis device is used to decompose the pollutants that are difficult to be decomposed by ordinary sewage biological treatment methods, and the macromolecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com