A high-strength permeable concrete suitable for sponge city construction and its preparation method

A permeable concrete and sponge city technology, applied in the field of concrete materials, can solve problems such as short service life, low structural strength, and easy damage, and achieve the effects of improving anti-aging, good corrosion resistance, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

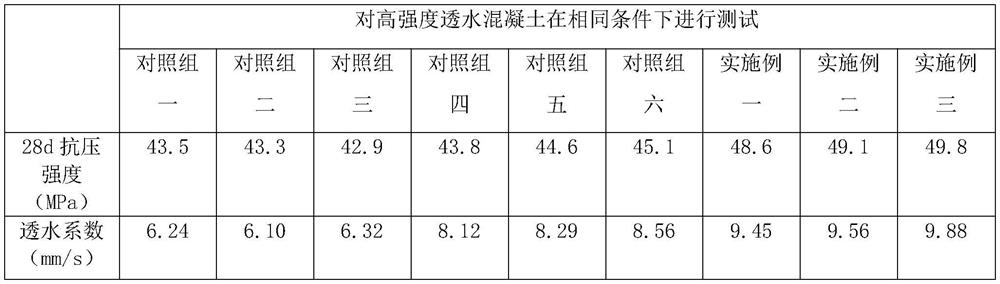

Examples

Embodiment 1

[0027] The present invention provides a high-strength permeable concrete suitable for sponge city construction, which comprises: 12.24% cement, 4.56% composite fiber, 3.26% composite reinforcing agent, 5.45% water, 0.224% Water reducing agent, 0.214% quick-setting and early strength agent, 74.052% aggregate; the composite fibers, calculated by weight percentage, include: 25.40% glass fiber, 28.30% basalt fiber, 46.30% polypropylene fiber; the The composite reinforcing agent, calculated by weight percentage, includes: 35.40% of nano-silicon dioxide, 27.50% of nano-zirconium diboride powder, and 37.10% of nano-silicon nitride;

[0028] The water-reducing agent is a polycarboxylate water-reducing agent; the quick-setting and early-strength agent is composed of triethanolamine, sodium silicate and lithium carbonate, and the mass ratio of the triethanolamine, sodium silicate and lithium carbonate is 3:4 :3;

[0029] The present invention also provides a preparation method of high-...

Embodiment 2

[0040] The difference from Example 1 is that it includes: 12.86% cement, 5.14% composite fiber, 3.84% composite reinforcing agent, 5.95% water, 0.246% water reducing agent, 0.236% quick-setting Early-strength agent, 71.728% aggregate; the composite fiber includes: 26.60% glass fiber, 28.90% basalt fiber, 44.50% polypropylene fiber according to the weight percentage; the composite reinforcing agent includes, according to the weight percentage : 36.60% nano silicon dioxide, 28.10% nano zirconium diboride powder, 35.30% nano silicon nitride.

Embodiment 3

[0042] The difference from Examples 1-2 is that, calculated by weight percentage, it includes: 12.55% cement, 4.85% composite fiber, 3.55% composite reinforcing agent, 5.70% water, 0.235% water reducing agent, 0.225% 72.89% of aggregate; the composite fiber includes: 26.00% glass fiber, 28.60% basalt fiber, 45.40% polypropylene fiber by weight; the composite reinforcing agent is based on weight The percentage calculation includes: 36.00% nano silicon dioxide, 27.80% nano zirconium diboride powder, 36.20% nano silicon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com