Double-target calibration device of thermal infrared imager and visible light camera and use method of double-target calibration device

A technology of infrared thermal imaging camera and calibration device, which is applied in the directions of instruments, image enhancement, image analysis, etc., can solve problems such as difficult application and complicated manufacturing cost, and achieve easy promotion and implementation, elimination of principle errors, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

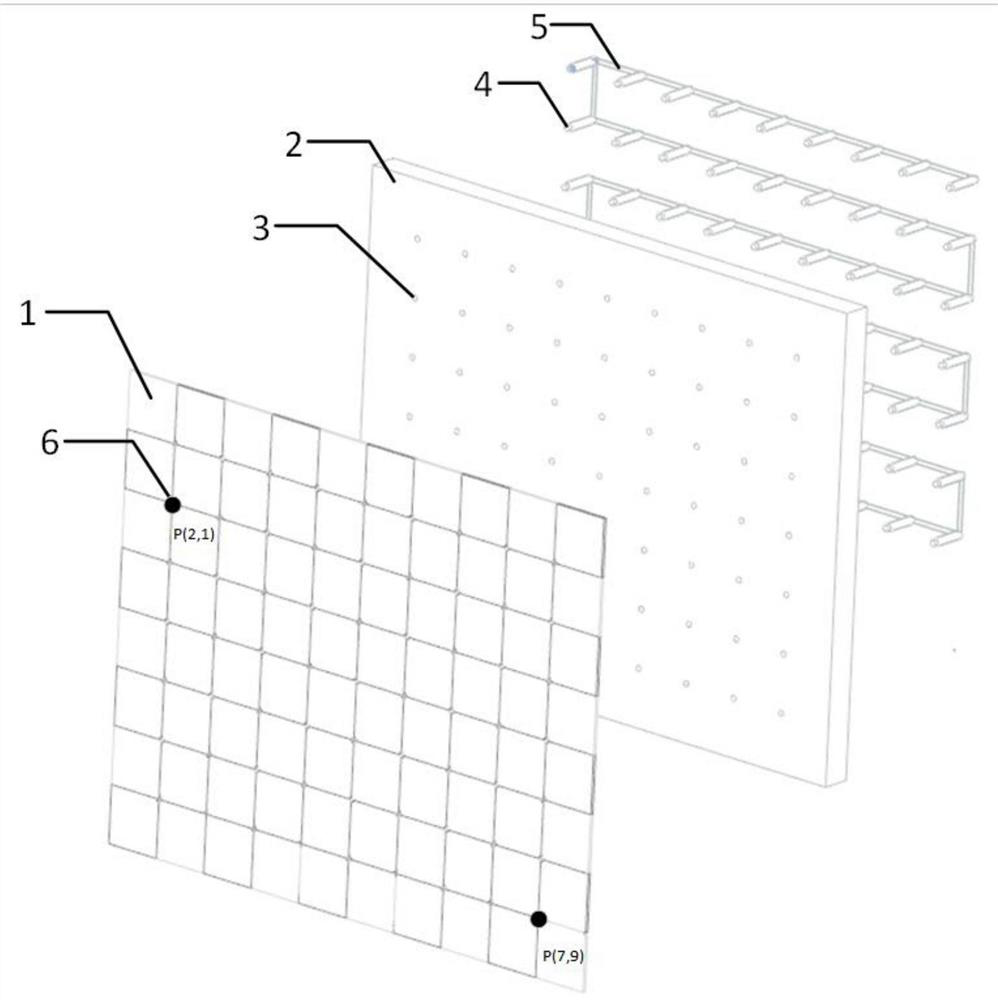

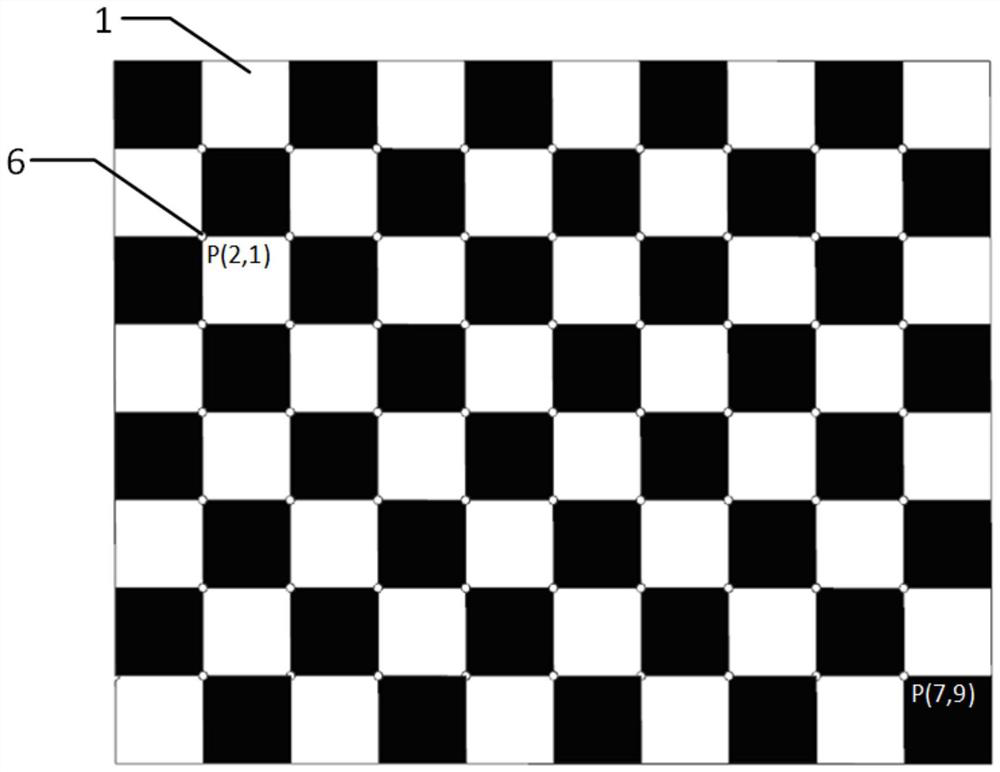

[0034] Such as figure 1 , 3 As shown, it includes: a calibration board 1 , N heating elements 4 , a controller (not shown in the figure) and a heat shield 2 arranged behind the calibration board 1 . N first through holes 6 arranged in a rectangular array are formed on the calibration plate 1 . The diameter of the first through holes 6 is 0.5-5 mm. The diameter of the first through holes 6 should be as small as possible to improve the calibration accuracy. A grid is drawn on the front surface of the calibration plate 1, the intersection of the straight lines in the grid is the first through hole 6, that is, the intersection coincides with the first through hole 6, and there is a heating element 4 in each first through hole 6 .

[0035] The lattices in the grid are filled with black and white, and the black lattices and white lattices are set at intervals. The heating element 4 is heated by electric heating, and the controller is electrically connected to N heating elements 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com