Liquid cooling plate with heating and temperature equalizing performance

A liquid-cooled plate and its own technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of low temperature heating temperature and unevenness of power batteries, and achieve the effect of temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

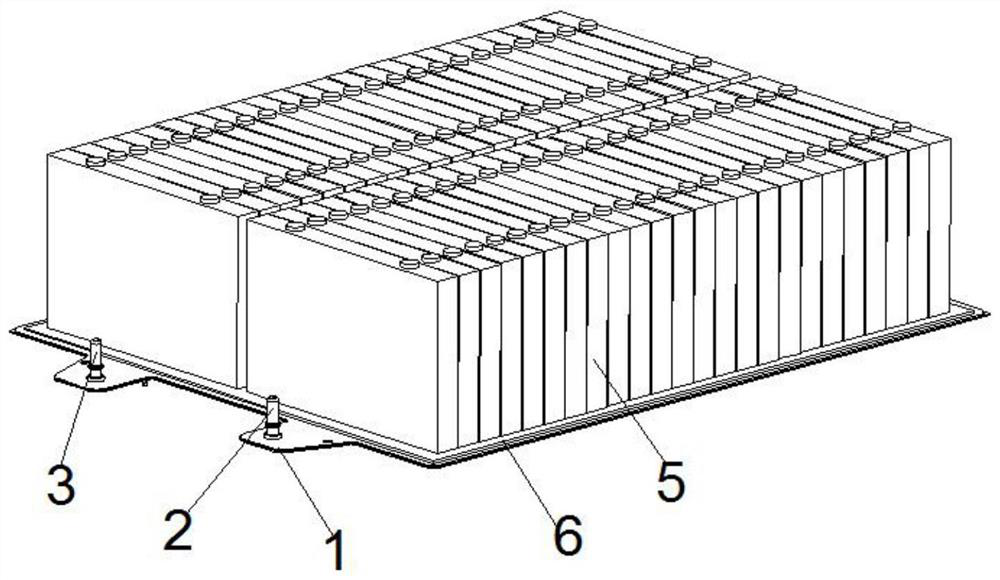

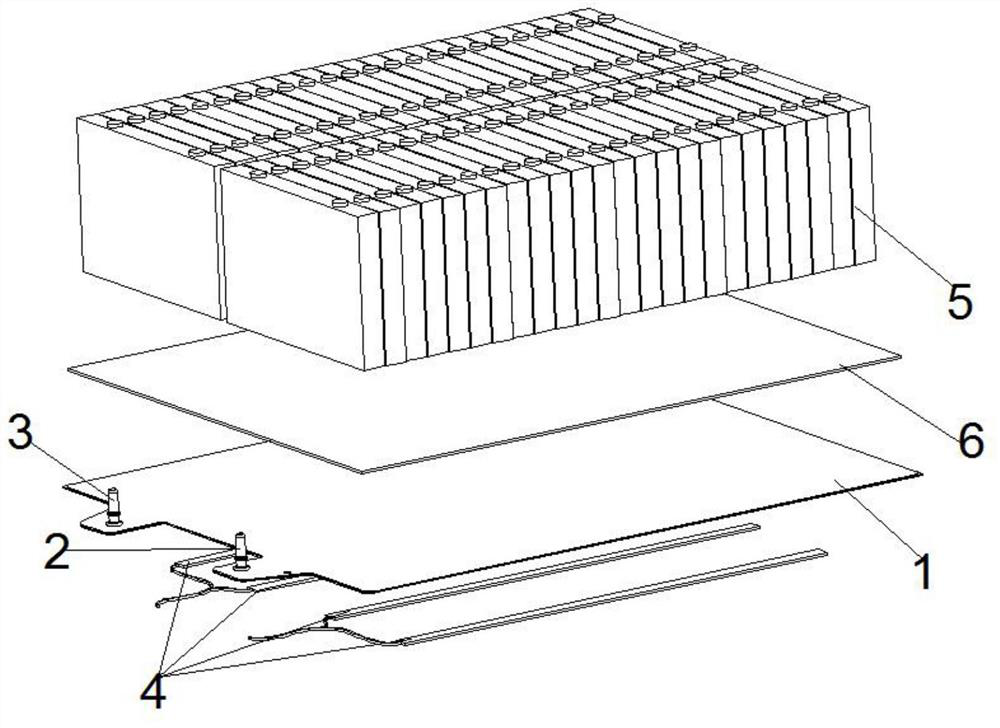

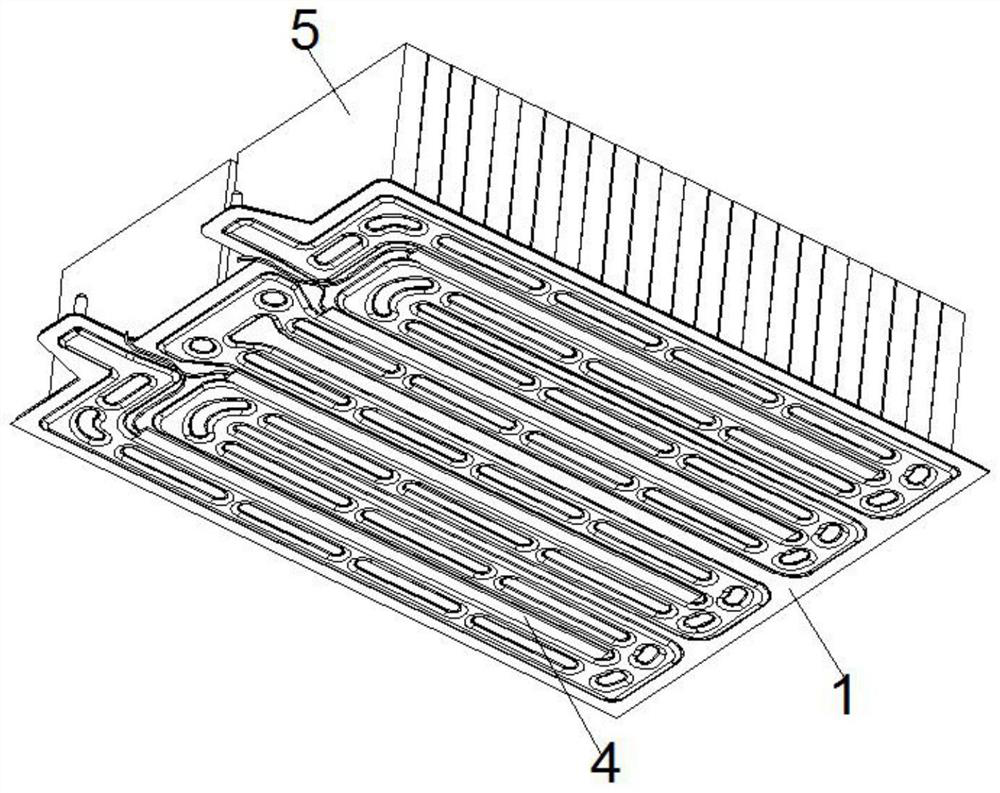

[0032] like Figure 1~4 As shown, the present invention has a liquid cooling plate with heating and uniform temperature performance, including a liquid cooling plate 1, one side of the liquid cooling plate 1 is connected to the water inlet 2 and the water outlet 3, and the bottom of the liquid cooling plate 1 Several heating chips 4 are installed on the liquid cold plate flow channel 7, the liquid cold plate 1 is provided with a silicone pad 6, the upper side of the silicone pad 6 is connected to the battery module 5, and the heating chips 4 are equally spaced Arranged, the heating chips 4 are connected in parallel.

[0033] In this embodiment, several heating fins 4 are arranged at equal intervals on the liquid cooling plate 1 and arranged in parallel. By controlling the start and stop of one or several heating fins 4, the purpose of temperature balance of the battery module 5 is achieved, and also It can ensure that the temperature difference of the battery module 5 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com