Sub-connector and wafer thereof

A technology of connectors and chips, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of inability to form differential pair circumferential shielding and differential pair shielding, and achieve structural strength assurance and convenience Effect of processing and enhancing the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

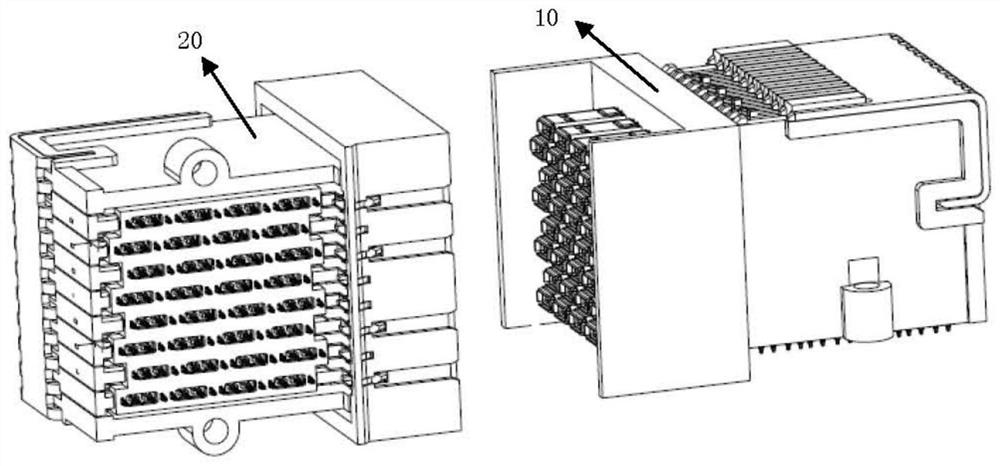

[0064] see figure 1 , a high-speed orthogonal connector of the present invention, including two matching sub-connectors, defining the contact end of the signal terminal as the shape of the receiving cavity, or a sub-connector whose contact end plays the role of the receiving cavity is a curved female The connector 10 defines that the contact end of the signal terminal is in a contained form and forms a needle-like form. Another sub-connector is a bent male connector 20, where "bent" means that the two ends of the connector have a 90° bend fold.

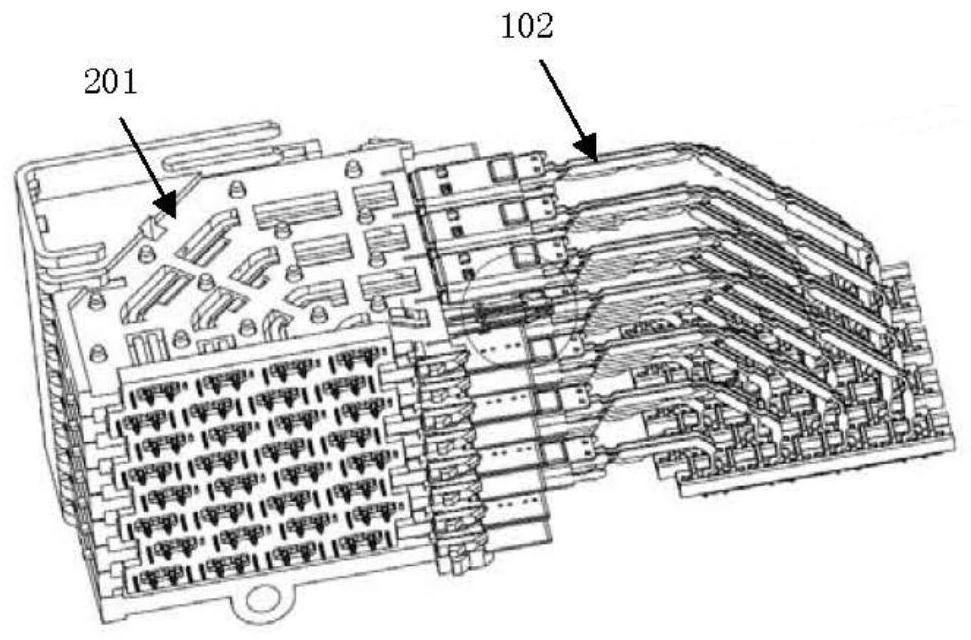

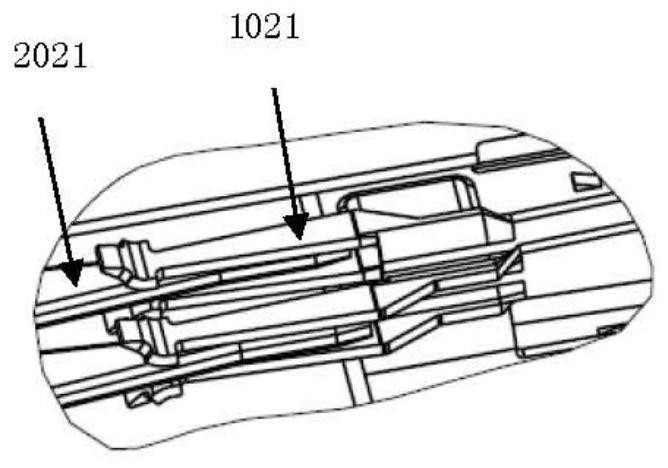

[0065] see figure 2 , the bent female connector includes a plurality of bent mother wafers 101 distributed in parallel, and the bent female signal terminal 102 on the same bent mother wafer has a contact end, a crimping end and a terminal body connecting the contact en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com