Wireless communication module test system

A technology of wireless communication module and testing system, which is applied in wireless communication, transmission system, digital transmission system, etc. It can solve the problems of inability to clamp and use heat dissipation effect, inconvenient detection of signal receiving sensitivity, etc., and achieve the convenience of testing status and viewing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

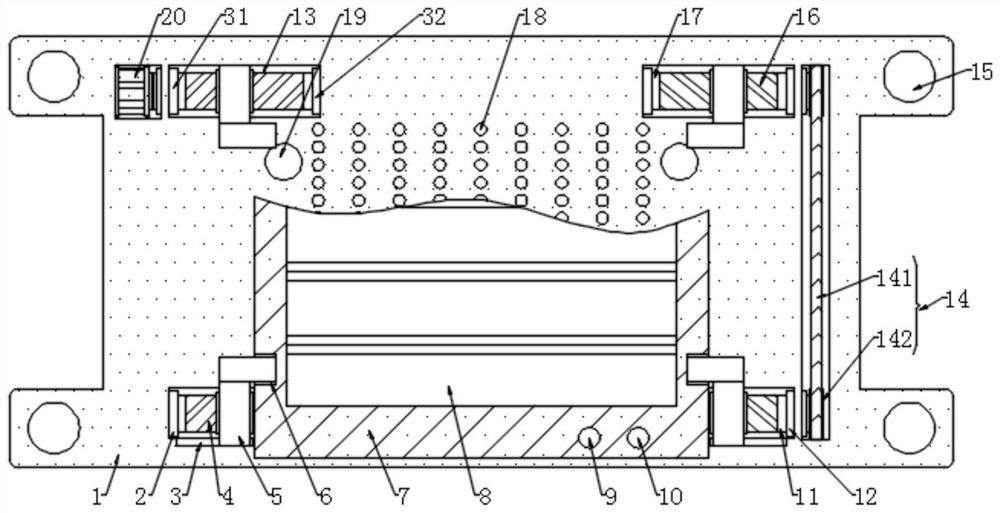

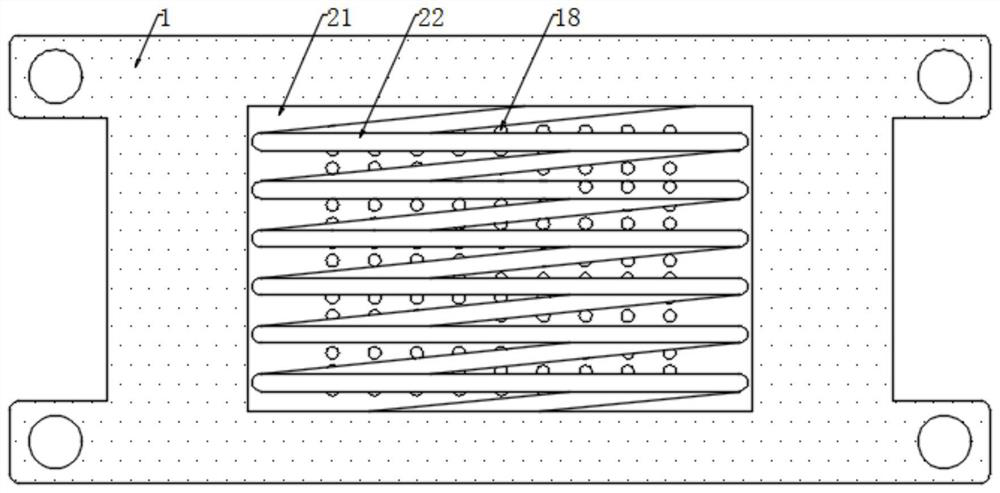

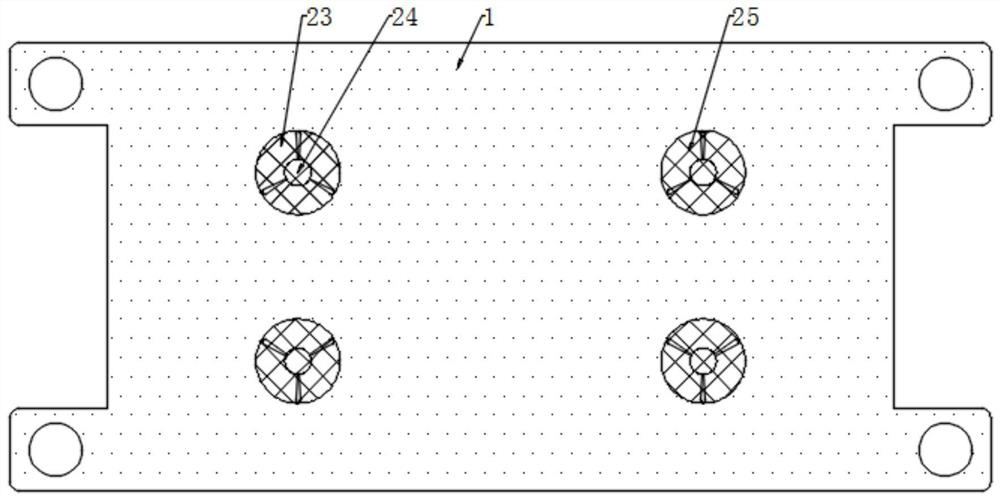

[0039] refer to figure 1 , figure 2 , image 3 and Figure 5 First, take the wireless controller 7, insert the positioning column 26 into the positioning groove 19 for preliminary fixing, then control the driving motor 20 to work through the external controller, and drive the positive thread column 4 and the reverse thread column 16 through the first rotating shaft 31 Rotate, and drive the gear 142 to rotate through the second rotating shaft 11, by means of the transmission effect of the tooth chain 141, drive another reverse thread post 16 and the positive thread post 4 to rotate through another gear 142 and another second rotating shaft 11, so that the limit block 5. Move in the direction of the wireless controller 7 until the limit block 5 is snapped into the limit groove 6, clamp and fix the wireless controller 7 again, and then the fan 24 and the semiconductor refrigerator 22 can be controlled to work through the external controller. After the external air is cooled, ...

Embodiment 2

[0041] refer to figure 1 and Figure 4 , during the testing process, the external equipment transmits information, and the wireless communication module 27 transmits the transmission data to the signal strength detection module 28 and the receiving sensitivity detection module 29 for classification, and then sends the classified data to the data processing center 30 respectively, and then through The analysis module 301 sends the data analysis and processing to the comparison module 302 for comparison with the set value, and sends the comparison data to the database 303 for storage, so that it can be viewed later. When it matches the set value, the data processing center 30 controls The green second warning light 10 lights up to indicate normal. When the set value is not met, the red first warning light 9 is controlled to light up to indicate that there is a problem, and the signal strength and receiving sensitivity are displayed linearly through the display screen 8 for easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com