Method and device for processing dough

A processing device and dough technology, applied in the direction of dough processing, dough extruder, dough cutting machine, etc., can solve the problems of structural damage, increase stickiness, affect product quality, etc., to reduce structural damage and reduce water release , The effect of process stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

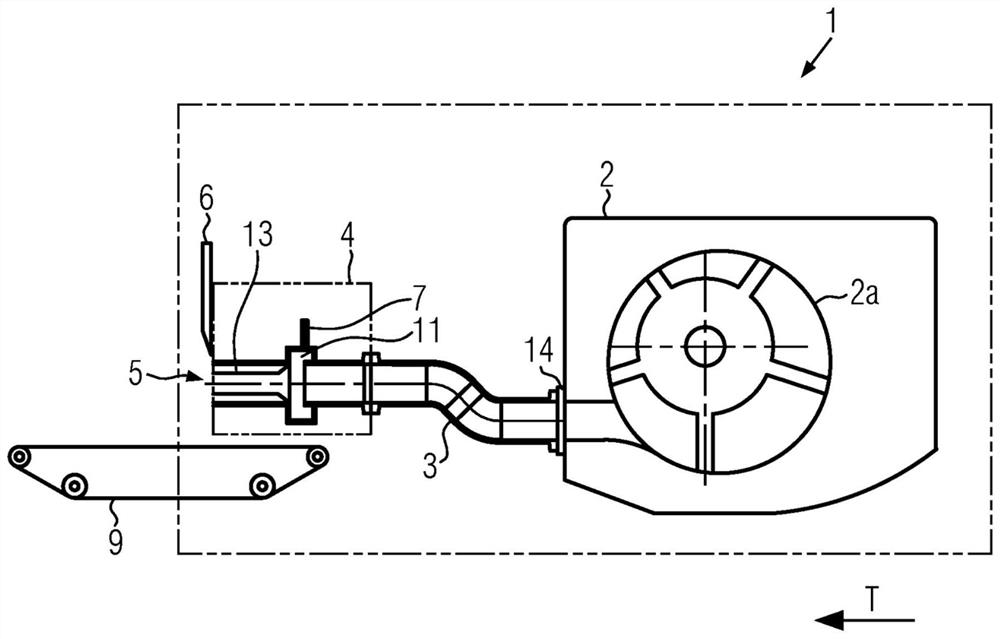

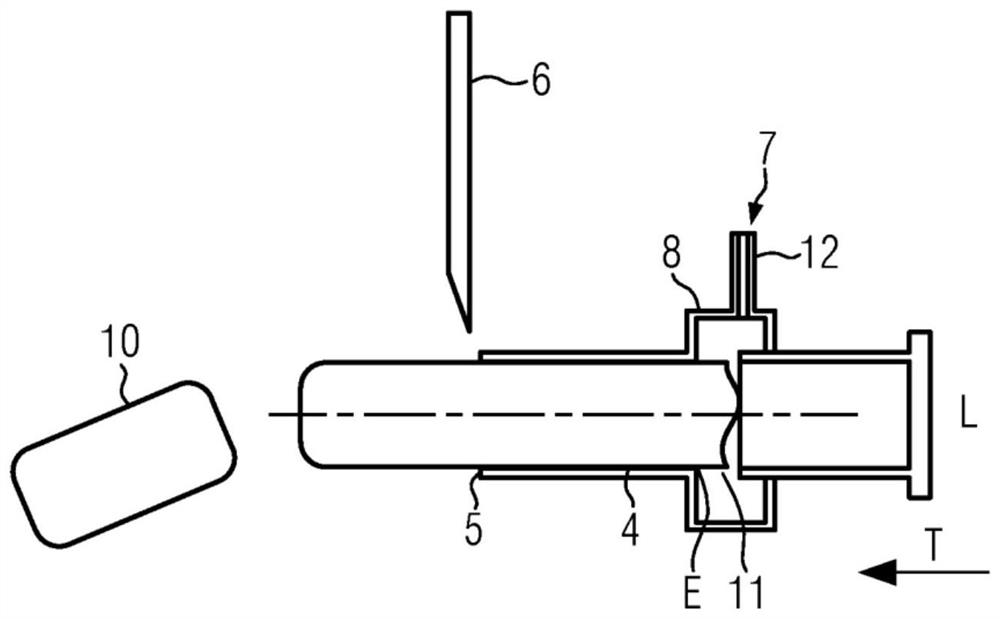

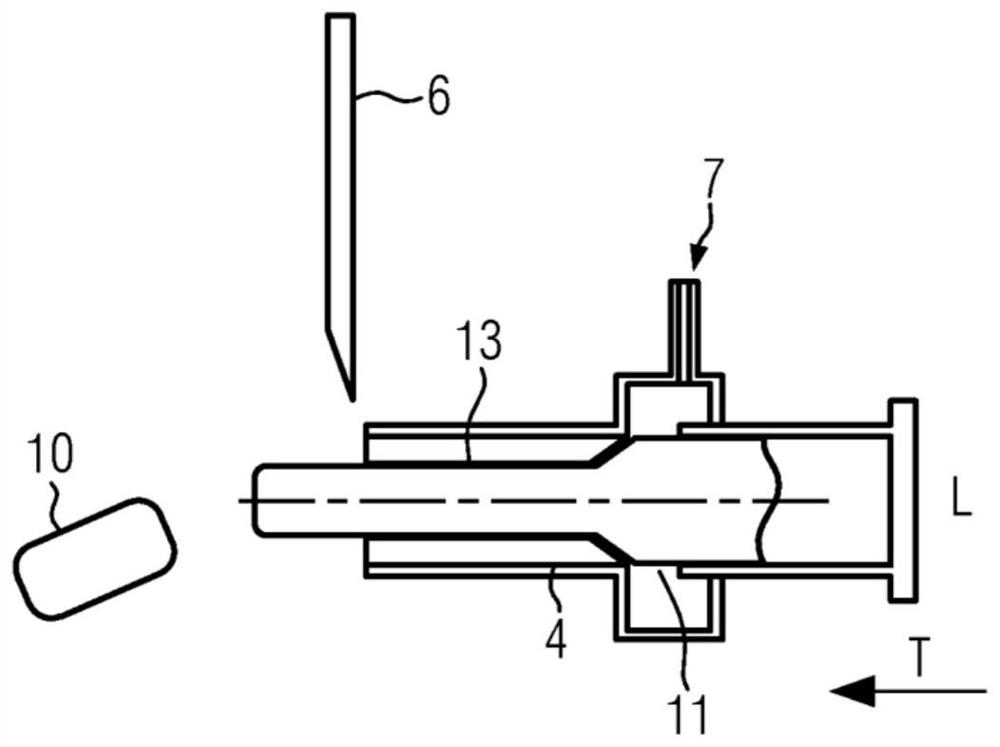

[0049] figure 1 A cross-sectional view of a dough divider 1 according to the invention is shown very schematically. The device according to the invention comprises a pump device 2 , by which is hereby meant a pump unit comprising a delivery mechanism 2 a, for example in the form of a vane pump. The pump device 2 can for example pump dough from a filling hopper or a mixing container with a mixer at the lower end and pump it in the form of dough strips into the pipes 4 , 3 adjoining the pump device 2 . The tube currently consists, for example, of a conveying tube 3 and an outlet tube 4 , wherein the tubes 3 , 4 comprise an outlet opening 5 through which the conveyed strips of dough 10 can exit. The pipe, presently the delivery pipe 3 , is connected to the pump device 2 via a pipe flange 14 . In this embodiment, eg in the transport direction T, a further transport device, eg in the form of a conveyor belt 9 , can be arranged downstream of the outlet opening 5 .

[0050] The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com