Novel efficient intelligent combined solid waste sorting device

A sorting device and high-efficiency technology, applied in sorting and other directions, can solve the problems of low sorting efficiency, low processing capacity, reduced sorting efficiency, etc., and achieve simple swing arm structure, high sorting efficiency, and grasping speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

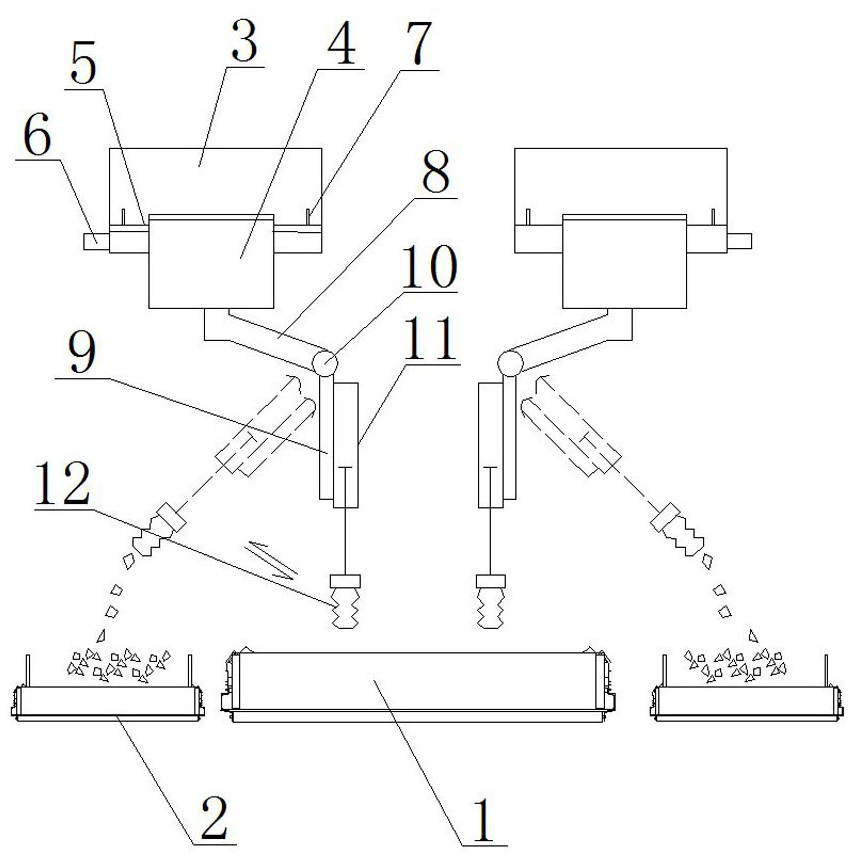

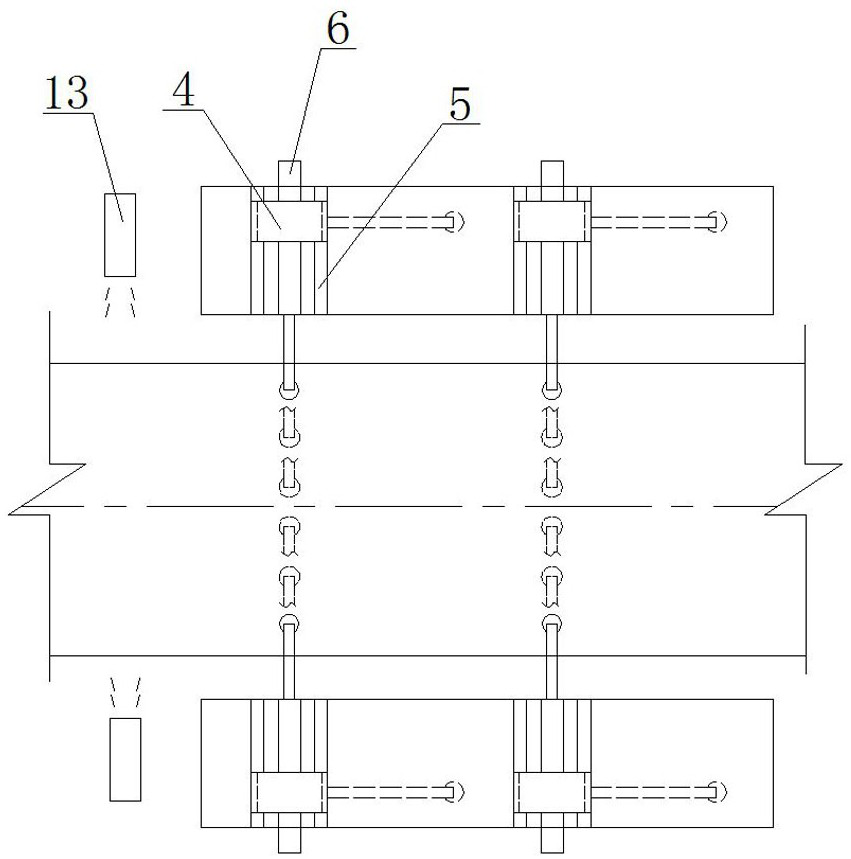

[0025] like figure 1 with figure 2 As shown, a novel high-efficiency intelligent combined fixation sorting device of the present invention includes a feed transport device 1, a product collecting device 2, and a number of sorting means, and the product collecting device 2 is disposed on the side surface of the feed transport device 1, several sorting devices. Symmert is provided on both sides of the raw material conveying device 1, the sorting device includes a rack 3, a suspension device 4, a suspension device driving mechanism, a rotary swing arm, and a grab device, and the suspension device 4 is slidably disposed on the frame 3 and is suspended. The drive mechanism is driven, and the upper end of the rotary swing arm is disposed on the lower side of the suspension device 4, and the grab device is fixed to the lower end of the rotary swing arm. The raw material conveying device 1 and the product collecting device 2 adopt a tape conveyor.

[0026] The lower side of the frame 3 is...

Embodiment 2

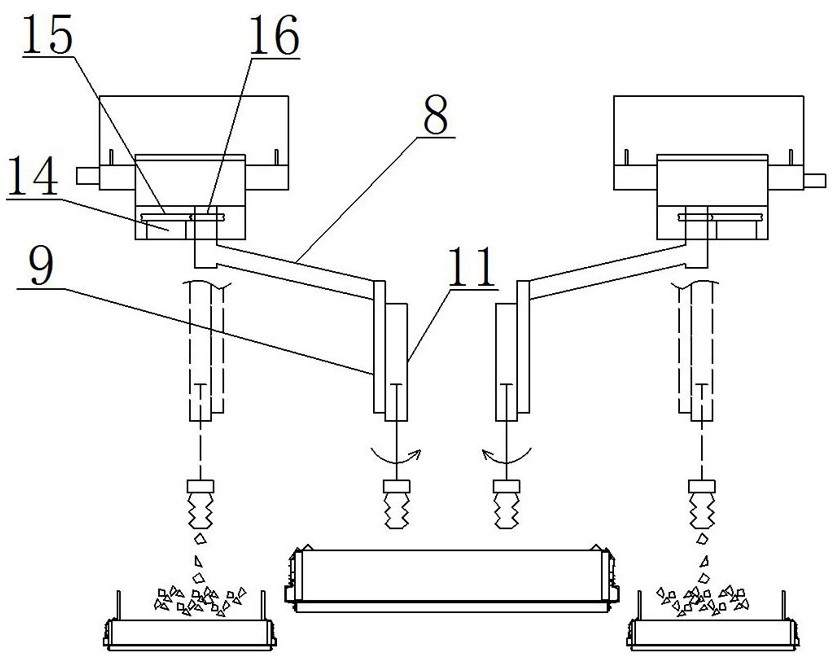

[0031] like image 3 As shown, a novel high-efficiency intelligent combined fixation sorting device of the present invention includes a feed transport device 1, a product collecting device 2, and a number of sorting means, and the product collecting device 2 is disposed on the side surface of the feed transport device 1, several sorting devices. Symmert is provided on both sides of the raw material conveying device 1, the sorting device includes a rack 3, a suspension device 4, a suspension device driving mechanism, a rotary swing arm, and a grab device, and the suspension device 4 is slidably disposed on the frame 3 and is suspended. The drive mechanism is driven, and the upper end of the rotary swing arm is disposed on the lower side of the suspension device 4, and the grab device is fixed to the lower end of the rotary swing arm. The raw material conveying device 1 and the product collecting device 2 adopt a tape conveyor.

[0032] The lower side of the frame 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com