Efficient double-material-belt synchronous stamping die

A stamping die and double-belt technology, applied in the field of high-efficiency double-belt synchronous stamping dies, can solve the problems of poor synchronization of double-material synchronous stamping dies, affecting stamping accuracy, and strip arching, etc., to achieve easy maintenance, ensure stability, The effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

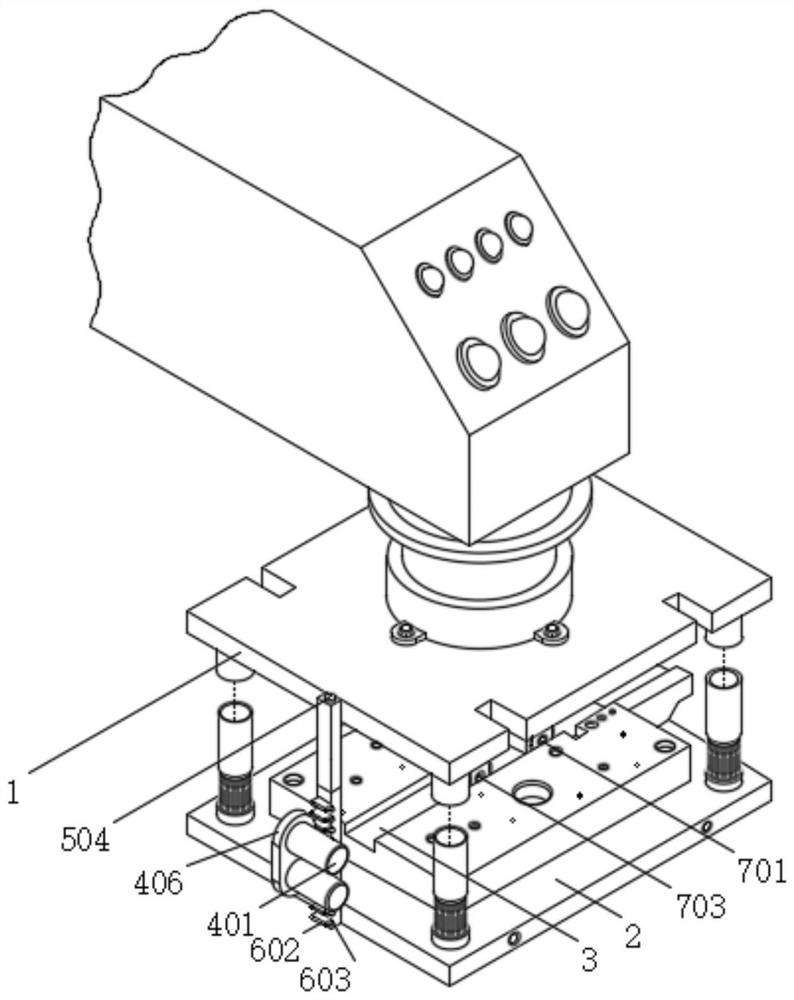

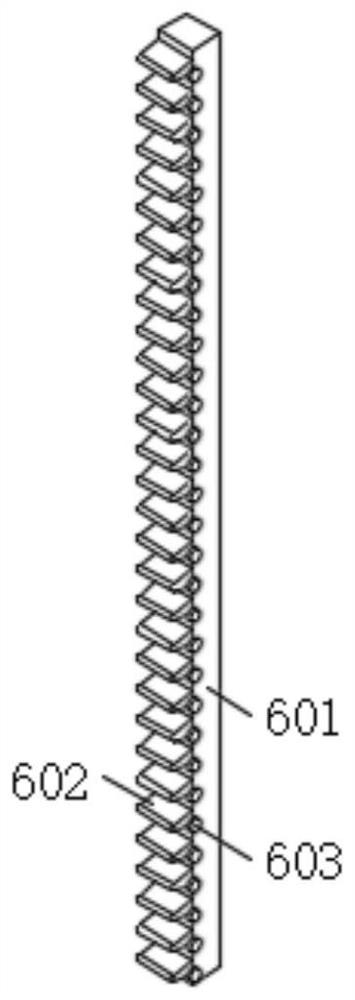

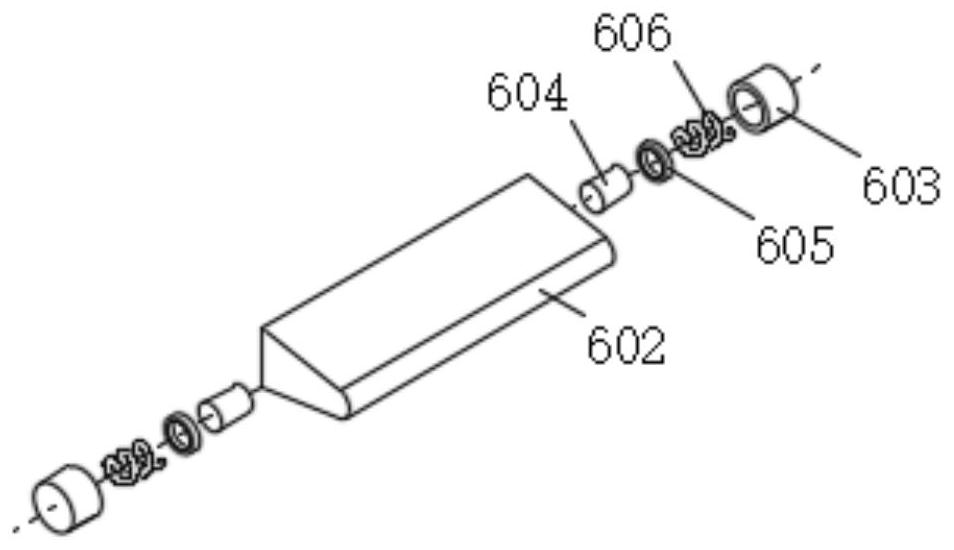

[0045] A high-efficiency double-belt synchronous stamping die, comprising an upper mold base 1, a lower mold base 2 is arranged below the upper mold base 1, and a feeding groove is opened at a position corresponding to the upper mold base 1 on the top of the lower mold base 2 3, and a feeding assembly 4 is fixedly connected to the position corresponding to the feeding groove 3 on the side end surface of the lower mold base 2, and the feeding assembly 4 is also equipped with a model matching assembly 5, and the side end surface of the feeding assembly 4 is engaged with The linkage assembly 6 is fixedly connected to the opposite surface of the upper mold base 1 , and the bottom of the upper mold base 1 is fixedly connected with a smoothing assembly 7 , and the smoothing assembly 7 is rollingly connected in the feeding trough 3 .

[0046] Specifically, such as Figure 4 As shown, the feeding assembly 4 includes two feeding rollers 401, and the two feeding rollers 401 are set corr...

Embodiment 2

[0060] A high-efficiency double-belt synchronous stamping die, comprising an upper mold base 1, a lower mold base 2 is arranged below the upper mold base 1, and a feeding groove is opened at a position corresponding to the upper mold base 1 on the top of the lower mold base 2 3, and a feeding assembly 4 is fixedly connected to the position corresponding to the feeding groove 3 on the side end surface of the lower mold base 2, and the feeding assembly 4 is also equipped with a model matching assembly 5, and the side end surface of the feeding assembly 4 is engaged with The linkage assembly 6 is fixedly connected to the opposite surface of the upper mold base 1 , and the bottom of the upper mold base 1 is fixedly connected with a smoothing assembly 7 , and the smoothing assembly 7 is rollingly connected in the feeding trough 3 .

[0061] Specifically, such as Figure 10 As shown, the smoothing assembly 7 includes a pressure wheel 701, the pressure wheel 701 is located inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com