High-activity lead-free solder paste and preparation method thereof

A lead-free solder paste, high activity technology, used in manufacturing tools, welding equipment, metal processing equipment and other directions, can solve the problems of easy to cause pillow effect, weak activity of solder paste, etc., to achieve the effect of mild reaction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

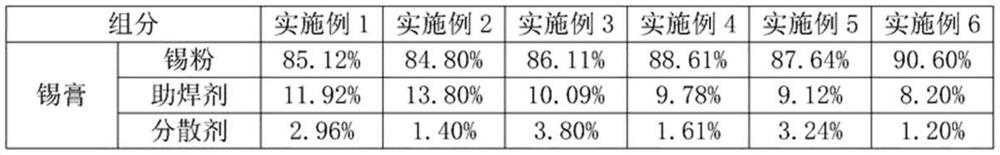

Embodiment 1

[0033]A highly active lead-free solder paste, comprising the following weight components, 85.12% tin flour, 11.92%, dispersant 2.96%, wherein the tin powder is dispensing, such as Table 2, the fluxed As described in Table 3, the dispersing agent is an oleic acid amide; the preparation method, including the following steps:

[0034] According to Table 2, the weight percentage of Table 3 refers to each component, backup; first add the solvent to the container, heated to 110 ° C, then add rosin, stir until the rosin is completely dissolved, maintain the temperature at 110 ° C, will touch The variable agent is added to the container, maintains the temperature and stir until completely dissolve; the temperature drops to 60 ° C, the active agent, the antioxidant, the temperature is maintained and stirred for 30 minutes; the mixture is ground to grasses at 4000 r / min. The diameter is less than 20 microns to obtain a flux; 11.92% of the fluxing and 85.12% tin powder and 2.96% dispersant...

Embodiment 2

[0036] A highly active lead-free tin cream comprising the following weight components, 84.8% tin flour, 13.8%, dispersing agent 1.4%, wherein the tin powder is dispensed, such as Table 2, the fluxed Group 3, for example, the dispersant is a mixture of ethyl bisteanamide and polyacryl dimethylsulfonate 1: 1 mixed; the preparation method, including the following steps:

[0037] According to Table 2, the weight percentage of Table 3 refers to the components, spare; add the solvent to the container, heated to 130 ° C, then add rosin, stir into the rosin completely dissolved, keep the temperature at 130 ° C, will thicken The agent is added to the container, maintains the temperature and stir it until it completely dissolves; the temperature drops to 50 ° C, the active agent, the antioxidant, the temperature is maintained and stirred for 25 minutes; the mixture was ground to the particle diameter of 5000 r / min. The flux is obtained; a 13.8% fluxing and 84.8% tin powder and 1.4% disper...

Embodiment 3

[0039] A highly active lead-free tin cream comprising the following weight components, 86.11% tin flour, 10.09%, dispersing agent 3.8%, wherein the tin powder is dispensed, such as Table 2, the fluxed As described in Table 3, the dispersing agent is a dual stearid amide; the preparation method includes the following steps:

[0040] According to Table 2, the weight percentage of Table 3 refers to each component, backup; add the solvent to the container, heated to 120 ° C, then add rosin, stir well completely dissolved, keep the temperature at 120 ° C, will throw The agent is added to the container, the temperature is maintained and stirred until completely dissolve; the temperature drops to 80 ° C, the active agent, the antioxidant, the temperature is maintained and stirred for 20 minutes; the mixture is grounded at 3000 r / min to ground the particle diameter at a rotational speed of 3000 r / min. 20 microns to obtain flux; 10.09% flux and 86.11% tin powder and 3.8% dispersant wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com