Novel anti-corrosion, noise-reducing, vibration-reducing and anti-seismic steel reinforced concrete diaphragm beam

A steel-reinforced concrete and steel beam technology, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as large noise and vibration at the beam end, corrosion of steel beams, increased driving impact of expansion joints at the beam end, etc., to improve rigidity , convenient construction, improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

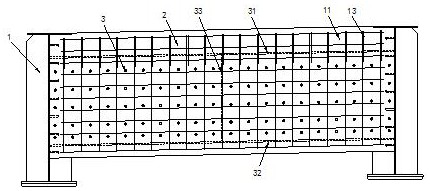

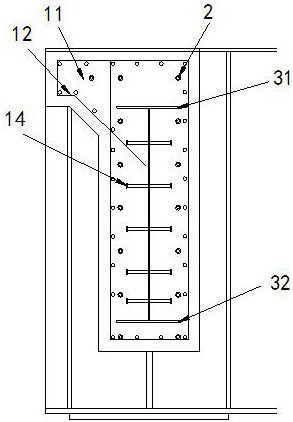

[0024] Example: see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

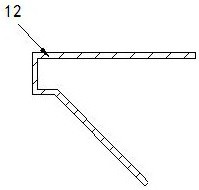

[0025] Its structure includes concrete blocks 1, shear nails 2, and steel beams 3. The outline of the concrete blocks 1 is in the shape of a 7-shaped structure. The shear nails 2 combine the steel beams 3 and the concrete blocks 1 to form a steel-reinforced concrete structure. , the steel beam 3 is wrapped in the concrete block 1, the two sides in the thickness direction of the web 33 are symmetrically arranged in multiple rows of the shear studs 2 in the height region of the concrete block 1, and the shear studs 2 of each row are arranged along the The length direction of the web 33 is arranged in parallel, the steel beam 3 includes an upper flange 31, a lower flange 32, and a web 33, the upper flange 31 is located at the inner upper end of the steel beam 3, and the lower flange 32 It is arranged at the inner lower end of the steel beam 3 , and the web 33 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com