Trowelling device for light plastering gypsum mortar construction

A plastering gypsum and mortar technology, which is applied in the field of lightweight plastering gypsum mortar construction equipment and equipment, can solve the problems of inconvenient ground cleaning, inconvenient construction efficiency, and low construction efficiency, and achieve the effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

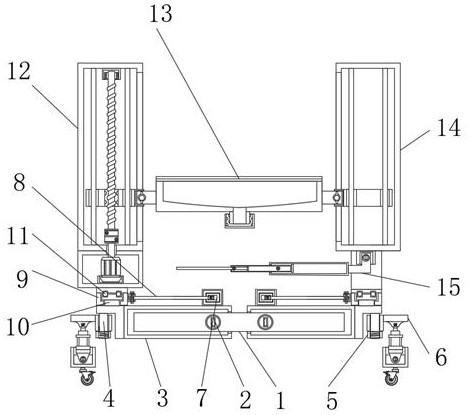

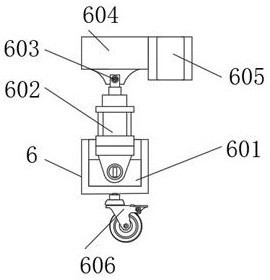

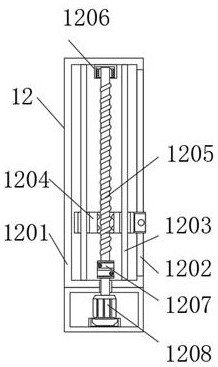

[0024] according to Figure 1-Figure 6 As shown, this embodiment provides a light-weight plastering gypsum mortar construction smoothing device, including a base 1, and both ends of the base 1 are fixedly sleeved with extension sleeves 3 through positioning bolts 2, so that The lower end of one side of the extension cover plate 3 is welded with a fixed rod 4, and the extension cover plate 3 is fixedly connected with a leveling mechanism 6 through the fixed rod 4 and the nut 5, and the upper end of the extension cover plate 3 is provided with an electric push rod 7 , the movable end of the electric push rod 7 is fixedly connected with a connecting rod 8 by a screw, and the other end of the connecting rod 8 is fixedly connected with a slider 9 by a screw, and the lower end of the slider 9 is provided with a slide rail 10, so A ball 11 is arranged between the slide block 9 and the slide rail 10, and the upper end of the slide block 9 is welded with a lifting mechanism 12, and a s...

Embodiment 2

[0035] according to Figure 7 and Figure 8 As shown, this embodiment provides a light-weight plastering gypsum mortar construction troweling device, in the light-weight plastering gypsum mortar construction troweling device, the inside of the mounting frame 1201 and the fixing frame 1401 are also welded Mounting block 16, the lower end of described mounting block 16 is fixedly connected with mounting bar 17 by screw, and the outer wall of mounting bar 17 is equidistantly provided with lamp holder 18, and a side interior of lamp holder 18 is equipped with laser emitter 19, so One side of the laser transmitter 19 is provided with a comparison rod 20, and the comparison rod 20 is fixedly connected to the inner side of the fixed frame 1401. Before the device is used, the aluminum alloy scraper 1301 can be disassembled by loosening the connecting bolt 1306, and then the installation rod 17 and the comparison rod 20 are fixed to the inside of the mounting block 16 by screws respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com