Stretchable pressure sensor array

A pressure sensor and pressure technology, which is applied in fluid pressure measurement, instrumentation, measurement force and other directions by changing ohmic resistance, can solve problems such as poor stretchability, small mechanical detection range, and complex data processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] One embodiment of the present invention provides a method for preparing the aforementioned stretchable pressure sensor array, including:

[0072] The step of preparing the pressure sensitive layer;

[0073] The step of preparing conductive layer;

[0074] The step of preparing encapsulation layer;

[0075] disposing the encapsulation layer on the surface of the conductive layer to form a flexible circuit board; and

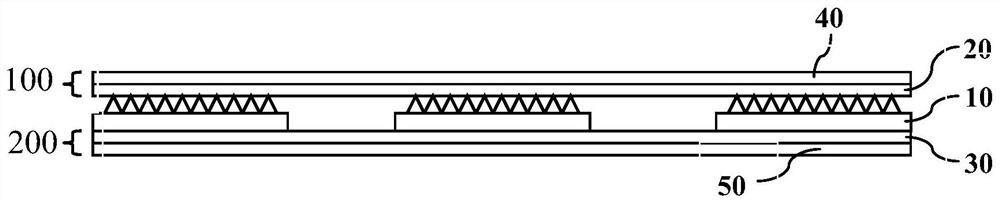

[0076] The pressure-sensitive layer is sandwiched between two flexible circuit boards to prepare a stretchable pressure sensor array.

[0077] In one embodiment, the process for preparing the pressure sensitive layer includes:

[0078] Add carbon-based powder to PDMS, planetary stirring to disperse evenly, then add curing agent and mechanically stir to prepare evenly dispersed carbon-based powder-PDMS composite slurry;

[0079] Add conductive ink to the carbon-based powder-PDMS composite slurry, and mechanically stir evenly to prepare conductive elastom...

Embodiment 1

[0093] (1) The conductive composition used includes 10wt% carbon fiber powder, 34wt% conductive ink and 56wt% polydimethylsiloxane (PDMS);

[0094] Add carbon fiber powder to PDMS, planetary stirring to disperse evenly, and then add curing agent to mechanically stir to obtain a uniformly dispersed carbon fiber-PDMS composite slurry; add conductive ink to carbon fiber-PDMS composite slurry, and mechanically stir to obtain a conductive Elastomer slurry; spread the conductive elastomer slurry on a smooth glass plate for curing to obtain a 700um thick flexible composite conductive film; cut the flexible composite conductive film into 16 cube pressure sensitive units of 1×1mm.

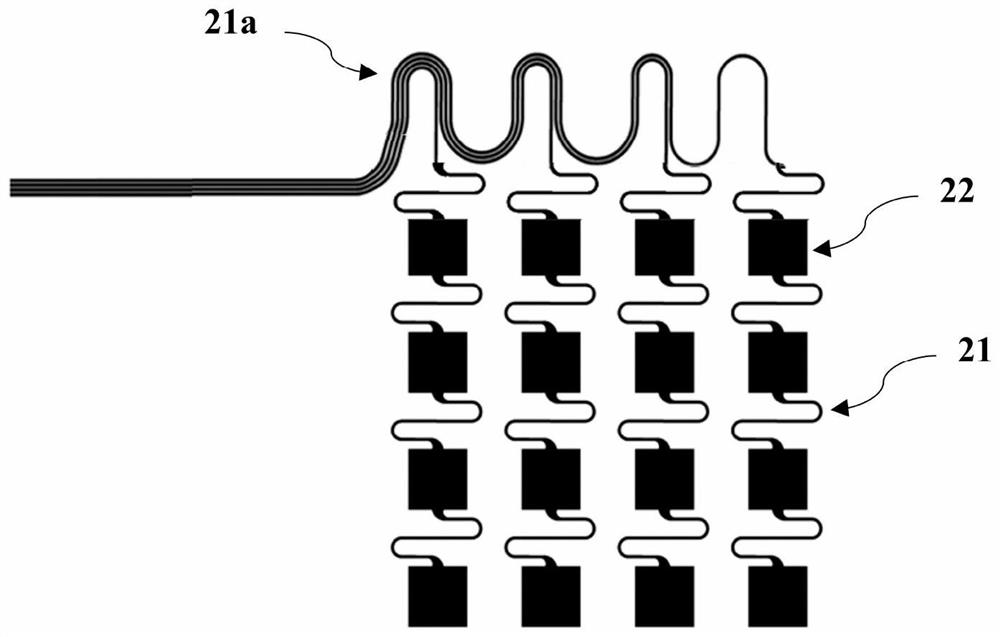

[0095] (2) Using copper foil as the base material, it is made by photoimaging pattern transfer and etching process such as image 3 As shown in the first electrode layer 20, the first electrode layer 20 includes 16 first conductive node parts 22 arranged in an array, and the connecting wire part 21a is wavy...

Embodiment 2

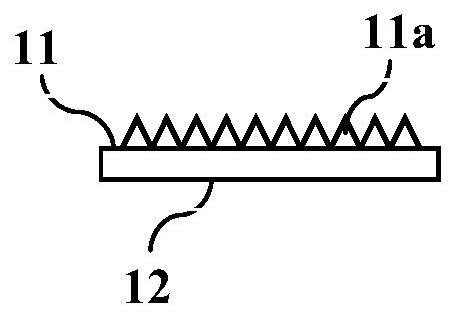

[0101] This embodiment uses the same raw materials, steps, process conditions, etc. as in Example 1. The only difference is that the step (1) of Example 1 makes a flat pressure-sensitive unit, and what this embodiment makes is a pressure-sensitive unit with a square pyramid. Pressure sensitive unit with raised structure. The preparation steps of the pressure sensitive unit are:

[0102] Use a laser cutting machine to engrave a quadrangular pyramid array with a gap distance of 0.2mm to make a pressure-sensitive layer patterned mold, in which the bottom surface of the quadrangular pyramid has a side length of 0.2×0.2mm and a height of 50um;

[0103] Add carbon fiber powder to PDMS, planetary stirring to disperse evenly, and then add curing agent to mechanically stir to obtain a uniformly dispersed carbon fiber-PDMS composite slurry; add conductive ink to carbon fiber-PDMS composite slurry, and mechanically stir to obtain a conductive Elastomer slurry; pour the prepared conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com